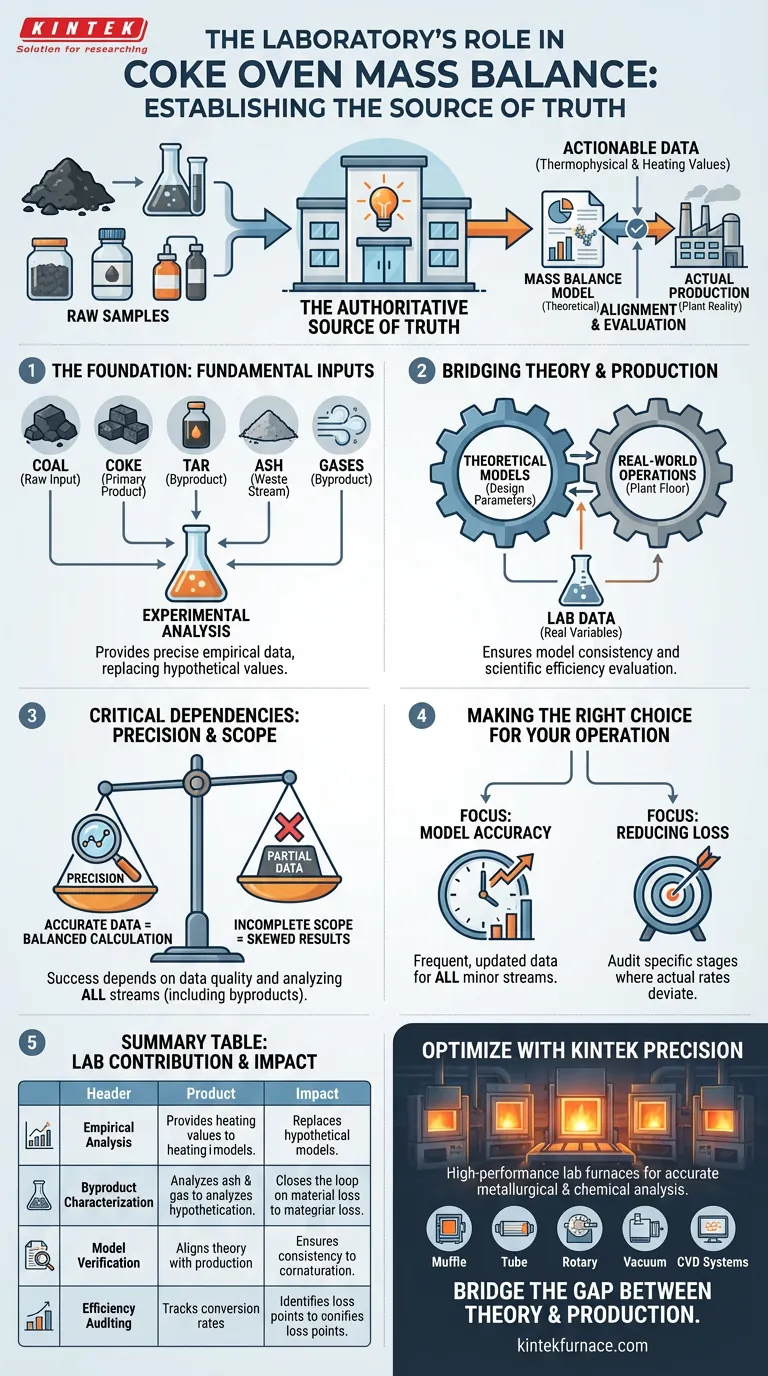

The laboratory serves as the authoritative source of truth for establishing an accurate mass balance in coke oven operations. It is responsible for generating the critical thermophysical data and heating values for all process materials—including coal, coke, tar, ash, and byproduct gases—which act as the fundamental variables for all balance calculations.

The laboratory transforms raw samples into actionable data, ensuring that theoretical mass balance models align with actual production conditions to allow for the scientific evaluation of material loss and efficiency.

The Foundation of Mass Balance Calculations

Providing Fundamental Inputs

Theoretical models for coke ovens cannot function in a vacuum; they require precise empirical data.

The laboratory provides these fundamental inputs by conducting experimental analysis. Without this verified data, mass balance calculations would remain hypothetical rather than practical tools for plant management.

Analyzing Diverse Material Streams

A complete mass balance requires accounting for every input and output stream.

The laboratory analyzes the specific characteristics of the raw input (coal) and the resulting products. This includes determining the heating values and physical properties of coke, tar, ash, and various byproduct gases.

Bridging Theory and Production

Ensuring Model Consistency

One of the primary challenges in process engineering is the discrepancy between design parameters and real-world operations.

Laboratory data ensures that theoretical models remain consistent with actual production conditions. By feeding real-world variables into the equations, the facility bridges the gap between engineering theory and the reality of the plant floor.

Evaluating Conversion Efficiency

Understanding where material goes is essential for optimizing the coking process.

With accurate lab data, operators can perform a scientific evaluation of conversion efficiency. This allows the facility to track material flow precisely and identify specific stages where material loss occurs.

Understanding the Dependencies

The Criticality of Data Precision

The output of a mass balance calculation is highly sensitive to the quality of the input data.

If the laboratory fails to provide accurate thermophysical characteristics, the entire scientific evaluation becomes compromised. An error in measuring the heating value of a byproduct gas, for example, will skew the energy balance and mask potential inefficiencies.

The Scope of Analysis

Partial data leads to incomplete conclusions.

To establish a valid mass balance, the laboratory cannot focus solely on the primary product (coke). It must maintain equal rigor in analyzing byproducts and waste streams (tar, ash, gases) to fully close the loop on material loss.

Making the Right Choice for Your Operation

To maximize the value of your laboratory facility in mass balance efforts:

- If your primary focus is model accuracy: Ensure the laboratory provides frequent, updated thermophysical data for all minor byproduct streams, not just coal and coke.

- If your primary focus is reducing loss: Use the laboratory's experimental data to audit specific process stages where the "actual" conversion rates deviate significantly from theoretical expectations.

Accurate laboratory data is the difference between guessing your plant's efficiency and scientifically controlling it.

Summary Table:

| Lab Contribution | Functional Benefit | Impact on Mass Balance |

|---|---|---|

| Empirical Analysis | Provides heating values for coal, coke, & tar | Replaces hypothetical models with real-world data |

| Byproduct Characterization | Analyzes ash and gas streams | Closes the loop on material loss and waste tracking |

| Model Verification | Aligns theoretical design with actual production | Ensures consistency between engineering and operation |

| Efficiency Auditing | Tracks conversion rates across process stages | Identifies specific points of material loss |

Optimize Your Coking Process with KINTEK Precision

Accuracy in mass balance begins with high-performance laboratory equipment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique metallurgical and chemical analysis needs. Whether you are analyzing coal samples or byproduct gas characteristics, our solutions provide the data precision required to maximize your plant's conversion efficiency.

Ready to bridge the gap between theory and production? Contact us today to find the perfect furnace for your laboratory!

Visual Guide

References

- Murat Ergul, Selçuk Selimli. An applied study on energy analysis of a coke oven. DOI: 10.2516/stet/2023042

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a reactor system control chlorine sources in oxychlorination? Master Catalyst Regeneration Control

- What are the primary technical objectives of CoCrFeMnNi alloy annealing? Master Recrystallization & Phase Control

- What advantages does a salt bath furnace offer for bainitic transformation? Achieve Superior Steel Microstructures

- What is the function of zone melting purification equipment in the preparation of CsPbBr3 perovskite single crystals? Key for 6N.

- What is sintering in the context of 3D printing? Unlock Dense, Functional Parts with Precision

- What role does a drying oven play in the final preparation of graphite oxide powder? Ensure Material Stability and Purity

- Why is carbon dioxide utilized for the in-situ gasification regeneration of NiCuCe catalysts? Enhance Catalyst Longevity

- Why is Barium Titanate annealed after SPS? Restore Material Stoichiometry and Electrical Performance