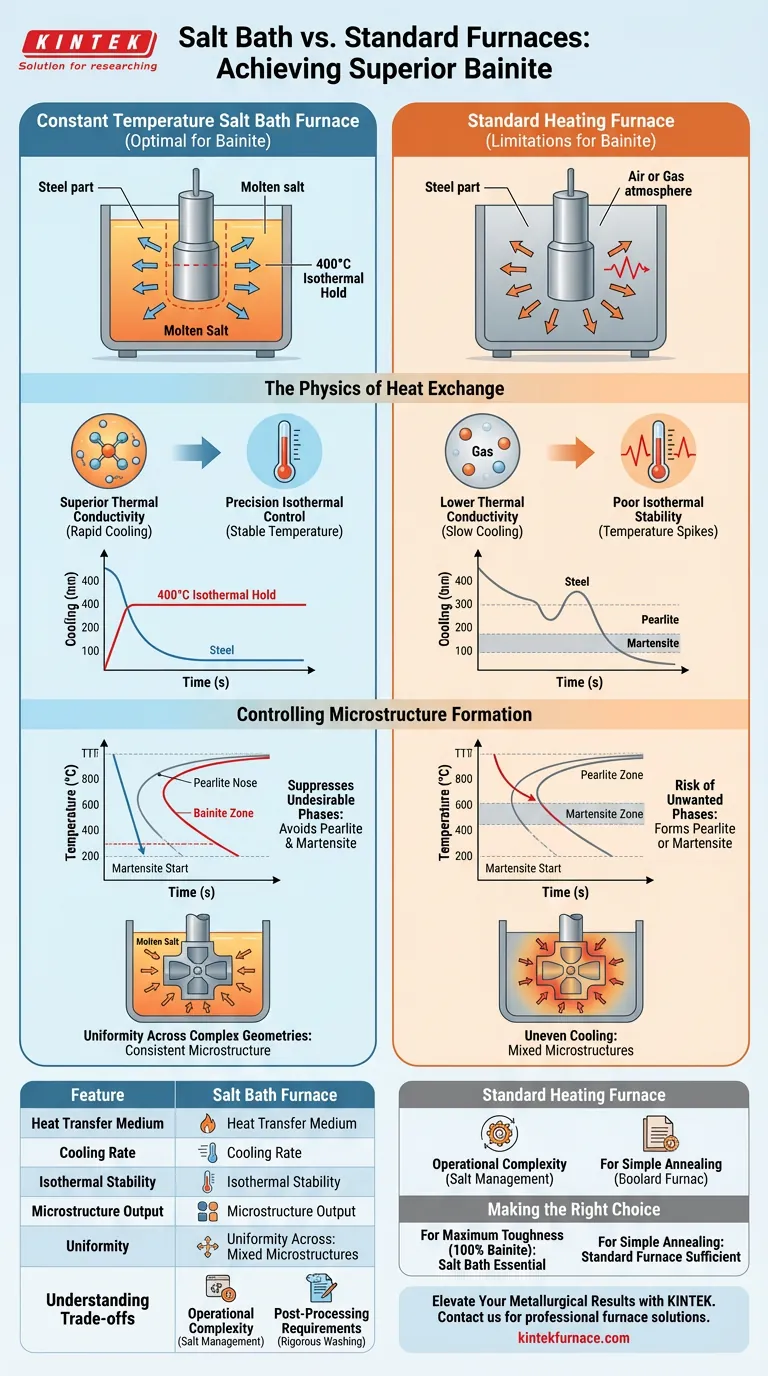

The decisive advantage of a constant temperature salt bath furnace is its superior heat transfer capability. Unlike standard heating furnaces that rely on air or atmosphere for cooling, a salt bath utilizes the high thermal conductivity of molten salt to rapidly lower the temperature of austenitized steel components to a precise isothermal holding point, such as 400°C. This specific capability is essential for bypassing unwanted microstructural phases that standard furnaces often fail to prevent.

By replacing air with molten salt as the heat transfer medium, manufacturers achieve the rapid cooling rates necessary to suppress pearlite and martensite formation. This ensures the steel stabilizes immediately at the target temperature, resulting in a consistent and high-quality bainitic transformation.

The Physics of Heat Exchange

Superior Thermal Conductivity

The primary limitation of a standard furnace during the cooling phase is the heat transfer medium: air or gas. Molten salt possesses significantly higher thermal conductivity than the gaseous atmospheres found in standard furnaces.

This allows the salt bath to extract heat from the steel component much faster than a standard furnace could. This efficiency is critical when the goal is to drop the temperature of the steel rapidly from austenitizing levels to the transformation range.

Precision Isothermal Control

Achieving bainite requires holding the steel at a fixed temperature (e.g., 400°C) for a specific duration. Standard furnaces often struggle with "thermal inertia," where the temperature fluctuates as a heavy load is introduced.

Because of the thermal mass of the molten salt, the bath maintains superior temperature stability. It absorbs the heat from the steel without significant temperature spikes, ensuring the environment remains strictly isothermal.

Controlling Microstructure Formation

Suppressing Undesirable Phases

The formation of bainite is a race against time and temperature. If cooling is too slow, the steel will transform into pearlite, which is softer and less ductile.

If the cooling is uncontrolled and drops too low, the steel will transform into martensite, which is hard but brittle.

The salt bath furnace rapidly cools the part past the "nose" of the pearlite curve but stops precisely before the martensite start temperature. This "stop-and-hold" capability is the defining feature that allows for pure bainitic transformation.

Uniformity Across Complex Geometries

In a standard radiation or convection furnace, parts with complex shapes may experience uneven cooling rates. Thinner sections cool faster than thick sections, leading to mixed microstructures.

Molten salt acts as a liquid medium that surrounds the entire part. This ensures uniform heat extraction across all surfaces simultaneously, resulting in a consistent microstructure throughout the component.

Understanding the Trade-offs

Operational Complexity

While salt baths offer superior metallurgical results for bainite, they introduce operational challenges not present in standard furnaces. Managing the chemistry of the molten salt is critical to prevent the salt from degrading or reacting with the steel surface.

Post-Processing Requirements

Unlike vacuum or atmosphere furnaces that may leave parts clean, salt bath processing requires rigorous washing. All traces of solidified salt must be removed from the components after the treatment to prevent corrosion.

Making the Right Choice for Your Project

The decision between a salt bath and a standard furnace depends entirely on the mechanical properties required of your final part.

- If your primary focus is maximum toughness and ductility: The salt bath is essential to ensure a 100% bainitic structure without brittle martensite.

- If your primary focus is simple annealing or normalizing: A standard furnace is sufficient, as rapid cooling rates and precise isothermal holding are not required.

For high-performance steel components where failure is not an option, the thermal precision of a salt bath is not just an advantage; it is a necessity.

Summary Table:

| Feature | Salt Bath Furnace | Standard Heating Furnace |

|---|---|---|

| Heat Transfer Medium | Molten Salt (High Conductivity) | Air or Gas (Low Conductivity) |

| Cooling Rate | Rapid (Suppresses Pearlite) | Slow (Risk of unwanted phases) |

| Isothermal Stability | High (High Thermal Mass) | Low (Prone to temperature spikes) |

| Microstructure Output | Consistent 100% Bainite | Mixed (Pearlite, Martensite) |

| Uniformity | Excellent for complex geometries | Variable depending on part shape |

Elevate Your Metallurgical Results with KINTEK

Don't settle for inconsistent microstructures. At KINTEK, we understand that precision is the difference between a high-performance component and a failure. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable high-temperature solutions tailored to your unique bainitic transformation needs.

Ready to optimize your heat treatment process? Our experts are standing by to design the perfect furnace for your laboratory or industrial application.

Contact KINTEK Today for a Professional Consultation

Visual Guide

References

- Impact Toughness and Fatigue Crack Propagation in Carbide‐Free Bainite: The Adverse Role of Retained Austenite and Martensite‐Austenite Islands. DOI: 10.1111/ffe.70025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is an automatically controlled mesh belt quenching line used for bearing rings? Precision & Stability Explained

- How does the precise control of heating rates affect sewage sludge biochar? Master Stability & Metal Stabilization

- How does a dual-stage salt bath design address steel wire sorbitization? Master Precision Gradient Cooling

- Why is a constant temperature oven required for CoCrFeNiMn alloy powders? Ensure Superior Defect-Free Deposition

- How is a vacuum oven utilized during the drying process of NVP/C gel? Ensure High Purity & Structural Integrity

- Why is a laboratory drying oven necessary for Co-Zr iron oxide nanopowders? Protect Material Integrity & Purity

- Why is high temperature control stability required for KAS method kinetics? Ensure Accurate Activation Energy Results

- What is the purpose of using a vacuum drying oven for mineral powders? Optimize Polymer Bonding and Density