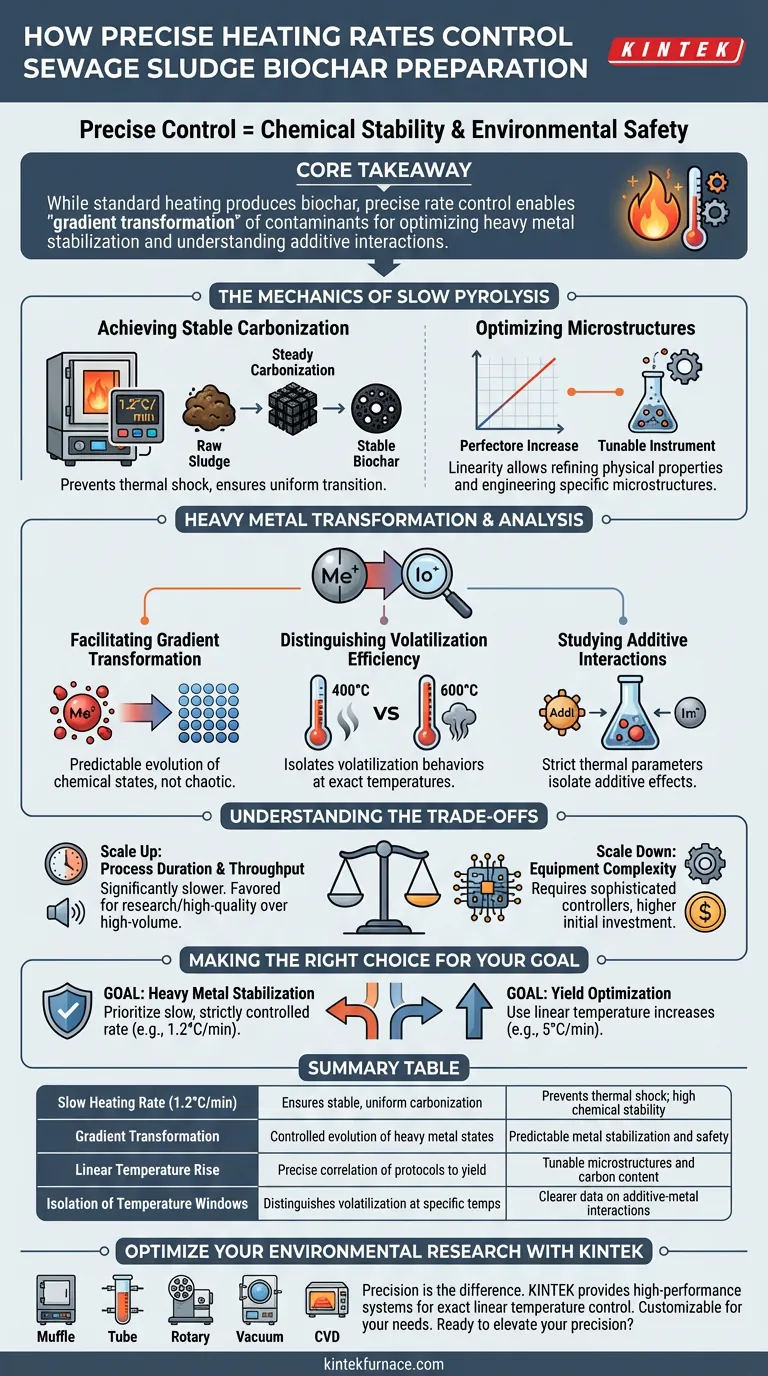

Precise control of heating rates determines the chemical stability and environmental safety of the final biochar product. By utilizing a programmable system to maintain specific rates, such as 1.2 degrees Celsius per minute, operators ensure the stable carbonization of organic matter while meticulously managing the complex transformation of heavy metals inherent in sewage sludge.

Core Takeaway While standard heating simply produces biochar, precise rate control enables the "gradient transformation" of contaminants. This specific modulation allows researchers to isolate volatilization behaviors at exact temperature windows, creating a necessary technical baseline for optimizing heavy metal stabilization and understanding additive interactions.

The Mechanics of Slow Pyrolysis

Achieving Stable Carbonization

A programmable temperature control system is essential for executing slow pyrolysis. By locking in a slow heating rate (e.g., 1.2°C/min), the system ensures that organic matter carbonizes steadily.

This prevents thermal shock to the material. It allows for a uniform transition from raw sludge to stable carbon structures.

Optimizing Microstructural Characteristics

Beyond basic stability, the linearity of the temperature increase is critical. Systems capable of precise linear increases serve as the technical foundation for refining the physical properties of the biochar.

This accuracy allows researchers to correlate specific heating protocols with biochar yield and carbon content. It turns the pyrolysis process into a tunable instrument for engineering specific microstructures.

Heavy Metal Transformation and Analysis

Facilitating Gradient Transformation

Sewage sludge frequently contains hazardous heavy metals, making their stabilization a primary concern. Precise heating control allows for the "gradient transformation" of these metals.

Rather than subjecting the metals to a chaotic thermal environment, the controlled rate allows for a predictable evolution of chemical states.

Distinguishing Volatilization Efficiency

High-precision control enables the isolation of specific temperature ranges, such as distinguishing effects at 400°C versus 600°C.

This allows researchers to observe exactly when and how efficiently different metals volatilize. It removes the ambiguity caused by temperature fluctuations common in less advanced systems.

Studying Additive Interactions

To remediate sludge effectively, additives are often introduced to bind heavy metals. The programmable control system provides the necessary basis for studying these mechanisms.

By maintaining strict thermal parameters, researchers can attribute changes in metal stability directly to the additives, rather than inconsistent heating profiles.

Understanding the Trade-offs

Process Duration and Throughput

The primary trade-off of such precise, slow heating (e.g., 1.2°C/min) is time. This method is significantly slower than flash pyrolysis or uncontrolled combustion.

It reduces the volume of material that can be processed in a given timeframe. It is favored for research and high-quality remediation over high-volume waste reduction.

Equipment Complexity

Achieving this level of linearity requires sophisticated programmable logic controllers.

Simple on/off heating elements cannot achieve the gradient control required for these specific heavy metal studies. This increases the initial capital investment for the furnace systems.

Making the Right Choice for Your Goal

To select the appropriate heating protocol for your sewage sludge biochar, consider your specific analytical needs:

- If your primary focus is Heavy Metal Stabilization: Prioritize a slow, strictly controlled rate (around 1.2°C/min) to facilitate gradient transformation and accurate interaction studies.

- If your primary focus is Yield Optimization: Use a system capable of linear temperature increases (e.g., 5°C/min) to systematically investigate the relationship between temperature and carbon content.

Precise heating control transforms pyrolysis from a crude disposal method into a calibrated science for environmental remediation.

Summary Table:

| Feature | Impact on Biochar Preparation | Primary Benefit |

|---|---|---|

| Slow Heating Rate (1.2°C/min) | Ensures stable, uniform carbonization | Prevents thermal shock; high chemical stability |

| Gradient Transformation | Controlled evolution of heavy metal states | Predictable metal stabilization and safety |

| Linear Temperature Rise | Precise correlation of protocols to yield | Tunable microstructures and carbon content |

| Isolation of Temperature Windows | Distinguishes volatilization at specific temps | Clearer data on additive-metal interactions |

Optimize Your Environmental Research with KINTEK

Precision is the difference between simple waste disposal and advanced environmental remediation. KINTEK provides high-performance laboratory equipment backed by expert R&D and manufacturing. Our Muffle, Tube, Rotary, Vacuum, and CVD systems are engineered for the exact linear temperature control required for gradient transformation studies and biochar engineering.

Whether you need custom heating profiles for sewage sludge analysis or high-temp furnaces for material synthesis, our systems are fully customizable to meet your unique laboratory needs.

Ready to elevate your pyrolysis precision? Contact us today to discuss your technical requirements!

Visual Guide

References

- Mahboub Saffari, Rezvan Mashayekhi. The fate and mobility of chromium, arsenic and zinc in municipal sewage sludge during the co-pyrolysis process with organic and inorganic chlorides. DOI: 10.1038/s41598-025-87169-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is Water Quenching Critical for Metastable Phases in Titanium? Unlock High-Performance Alloy Strength

- What role does a vertical heating furnace play in the production of nano-glass composites? Precision Shaping Experts

- How does oxygen flow at 2 to 8 SLPM regulate PS-PVD coating quality? Master Thermal Barrier Integrity

- What are the objectives of melt stirring and insulation treatment during the Al-5Er-Ti master alloy preparation process?

- Why is a sealed heating vessel used with a stepped heating process to infiltrate sulfur? Maximize Li-S Battery Performance

- What challenges are associated with batch furnaces? Overcome Inefficiency and Quality Issues

- How does high-temperature substrate heating at 500 °C facilitate TiO2 formation? Enhance Film Density and Quality

- How does an aluminum foil mask regulate temperature in the Floating-Zone process? Optimize Crystal Growth Precision