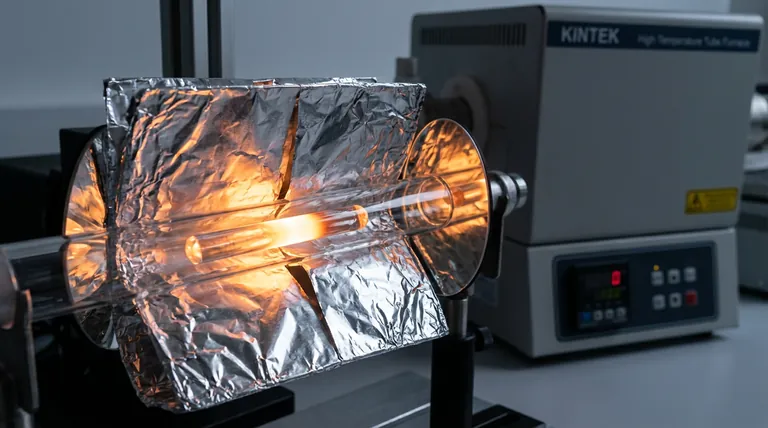

In the optical Floating-Zone process, an aluminum foil mask functions primarily as a high-precision optical shield. By wrapping the exterior of the quartz tube and leaving only a specific central opening, the foil blocks high-angle scattered radiation, preventing it from heating the sample outside the intended melt zone.

By restricting light entry to a precise aperture, the aluminum mask significantly sharpens the vertical temperature gradient at the liquid-solid interface. This thermal control creates distinct melt zone boundaries, which is critical for suppressing constitutional supercooling and preventing crystal cracking.

The Mechanics of Optical Shielding

Blocking Stray Radiation

Optical furnaces naturally generate scattered light that creates a broad, unfocused heating effect.

The aluminum foil mask intercepts this high-angle scattered radiation. It acts as a physical barrier, ensuring that only directed light reaches the sample.

Defining the Heating Aperture

The mask is applied to the exterior of the quartz tube with deliberate gaps.

This configuration forces light to pass only through the central opening. Consequently, the heat source is spatially confined, rather than being allowed to wash over the adjacent solid portions of the crystal rod.

Enhancing the Thermal Gradient

Sharpening the Interface

The direct result of this shielding is a drastic enhancement of the vertical temperature gradient.

Instead of a gradual temperature drop-off, the transition from the molten zone to the solid crystal becomes steep and abrupt. This mimics the ideal conditions required for high-quality crystal growth.

Clarifying Melt Boundaries

Without shielding, scattered light can cause the melt zone to appear diffuse or "mushy."

The aluminum mask eliminates this thermal noise, resulting in clearer melt zone boundaries. This visual and thermal clarity allows operators to maintain tighter control over the solidification front.

Why High Gradients Matter for Crystal Quality

Suppressing Constitutional Supercooling

A shallow temperature gradient often allows the liquid to cool below its freezing point ahead of the actual interface (constitutional supercooling).

By enforcing a steep thermal gradient, the mask ensures the melt remains stable until the exact moment of crystallization. This suppression is vital for maintaining a planar growth front.

Preventing Structural Failure

Uncontrolled thermal profiles are a primary cause of mechanical failure in growing crystals.

By regulating the gradient and removing stray heat, the mask helps prevent crystal cracking. It creates a more stable thermal environment that reduces the likelihood of stress-induced defects.

Understanding the Precision Required

The Importance of Gap Geometry

While the mask is a simple tool, its application requires precision.

The effectiveness of the regulation depends on the specific gaps left in the foil. If the opening is too wide, the shielding effect is lost; if too narrow, the melt zone may become starved of heat.

Alignment Sensitivity

The mask must be perfectly aligned with the optical focal point of the furnace.

Misalignment between the foil aperture and the light source can lead to asymmetric heating, potentially destabilizing the floating zone despite the improved gradient.

Making the Right Choice for Your Goal

To effectively utilize an aluminum foil mask in your setup, consider your specific defect challenges:

- If your primary focus is eliminating inclusions: Use the mask to steepen the gradient, which suppresses constitutional supercooling and keeps the growth front planar.

- If your primary focus is mechanical integrity: Implement the mask to sharpen melt boundaries, as this reduces the thermal noise that often leads to crystal cracking.

Correctly shielding your melt zone turns a broad, diffuse heat source into a precision tool for defect-free crystal growth.

Summary Table:

| Feature | Function of Aluminum Foil Mask | Impact on Crystal Growth |

|---|---|---|

| Radiation Control | Blocks high-angle scattered/stray light | Prevents unintended heating of solid rods |

| Aperture Definition | Constrains light to a precise central opening | Creates sharp, distinct melt zone boundaries |

| Thermal Gradient | Increases vertical temperature gradient | Suppresses constitutional supercooling |

| Structural Integrity | Reduces thermal noise and stress | Minimizes crystal cracking and defects |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect thermal gradient is the difference between a flawed sample and a high-quality single crystal. At KINTEK, we understand the nuances of high-temperature thermal profiles. Backed by expert R&D and manufacturing, we offer a comprehensive range of laboratory solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Our furnaces are fully customizable to meet your unique research needs, ensuring you have the precise control required for advanced crystal growth and material characterization. Don't let scattered radiation compromise your results—Contact KINTEK today to discover how our high-temperature expertise can drive your next breakthrough.

References

- Naoki Kikugawa. Recent Progress of Floating-Zone Techniques for Bulk Single-Crystal Growth. DOI: 10.3390/cryst14060552

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does high-temperature substrate heating at 500 °C facilitate TiO2 formation? Enhance Film Density and Quality

- Why must Sm:YAG ceramics undergo air annealing? Restoring Optical Clarity and Restructuring Defects

- What is the significance of using a hydrogen etching process in a reaction chamber? Mastering SiC Surface Preparation

- What are the advantages and disadvantages of dental porcelain? Achieve a Perfect Balance of Aesthetics & Durability

- Why is precise temperature control in an aging oven critical for ZK61 alloys? Master the 175°C Pre-aging Threshold

- How does a high-temperature annealing furnace regulate cold-rolled steel? Optimize Manganese Steel Performance

- How does the SCRS model simplify furnace combustion simulation? Efficiency Meets Accuracy in Thermal Modeling

- What role does an oscillating furnace play in the synthesis of quaternary Ge-Se-Tl-Sb glass alloys? Ensure Homogeneity