A high-temperature annealing furnace regulates material properties by providing a precise thermal environment—typically around 800°C—to induce complete recrystallization of the cold-rolled microstructure. This thermal treatment relieves internal stresses and transforms the deformed material into a uniform, fine-grained austenitic structure, directly determining the steel's final mechanical performance.

The furnace acts as a microstructural regulator, balancing conflicting properties by simultaneously eliminating work-hardening stresses and enabling the precipitation of strengthening phases. This results in a material that possesses both ultra-high yield strength and the ductility required for complex forming.

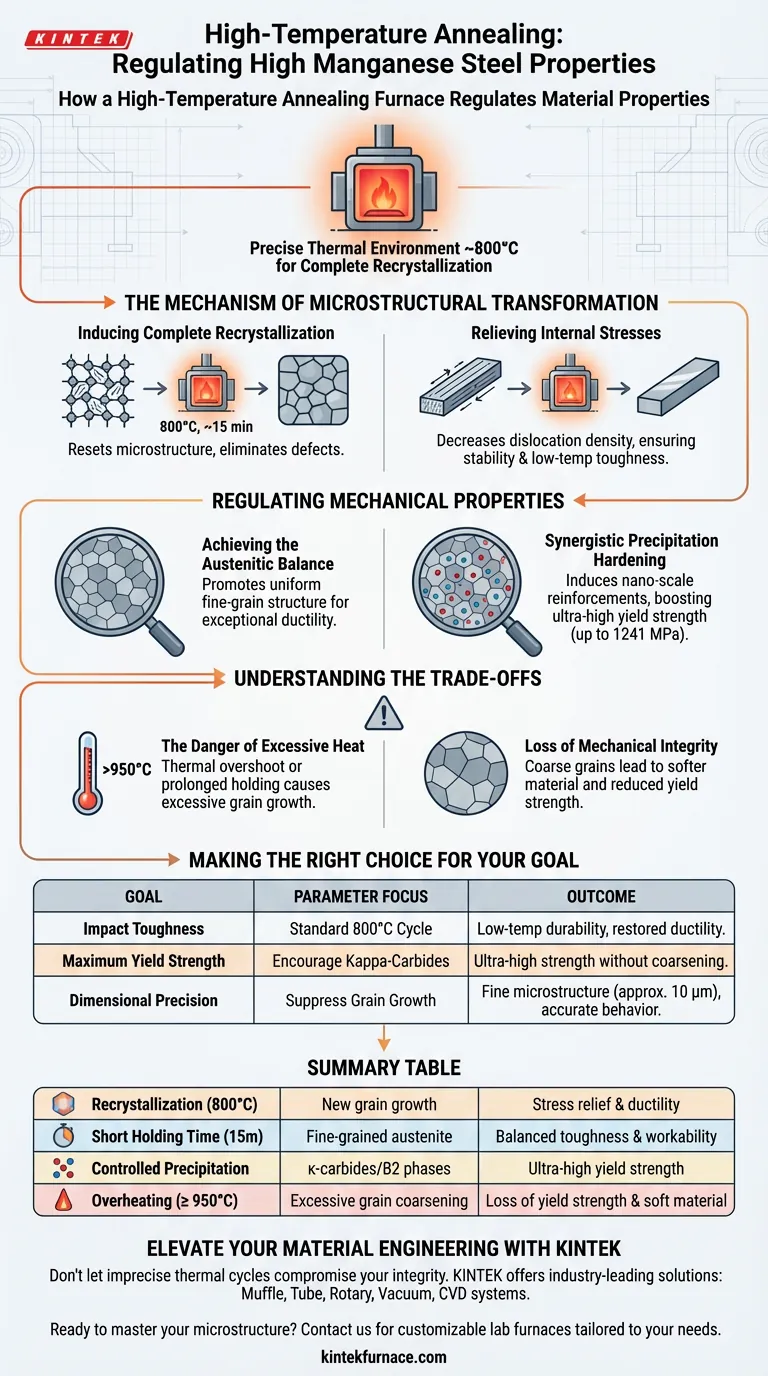

The Mechanism of Microstructural Transformation

Inducing Complete Recrystallization

The primary function of the furnace is to facilitate recrystallization. Cold rolling creates a highly stressed, deformed microstructure that is strong but brittle.

By holding the material at 800°C for approximately 15 minutes, the furnace provides the thermal energy necessary for new, strain-free grains to nucleate and grow. This process effectively resets the microstructure, eliminating the defects introduced during cold rolling.

Relieving Internal Stresses

During the cold-rolling process, significant residual stresses accumulate within the steel lattice. Without thermal regulation, these stresses would lead to premature failure or warping during use.

The annealing furnace acts as a stress-relief chamber. As the steel reaches the target temperature, the dislocation density decreases, ensuring the final product is dimensionally stable and tougher, particularly for low-temperature applications.

Regulating Mechanical Properties

Achieving the Austenitic Balance

The precise thermal control of the furnace promotes the formation of a uniform austenitic fine-grain structure. Austenite is critical for high manganese steels because it provides exceptional ductility.

This structural transformation allows the steel to achieve an optimal balance, offering the toughness to resist fracture while maintaining the ability to deform plastically without breaking.

Synergistic Precipitation Hardening

Beyond simple recrystallization, the furnace's thermal field can induce the precipitation of nanometer-scale kappa-carbides and B2 phases. These precipitates act as reinforcements within the steel matrix.

When the furnace environment is tightly controlled, these precipitates work synergistically to boost the material's ultra-high yield strength (potentially reaching 1241 MPa) without compromising the ductility gained from the austenitic structure.

Understanding the Trade-offs

The Danger of Excessive Heat

While high heat is necessary for recrystallization, the furnace must prevent thermal overshoot. If the temperature exceeds the optimal window (e.g., significantly above 950°C) or the holding time is too long, excessive grain growth will occur.

Loss of Mechanical Integrity

Large grains are detrimental to the material's yield strength. The furnace's precision is critical because it must hold the temperature high enough to recrystallize the steel, but low enough to maintain a fine grain size (often at the 10-micrometer scale).

Failure to regulate this upper limit results in a material that is softer and less capable of bearing high loads, negating the benefits of the alloy.

Making the Right Choice for Your Goal

To maximize the performance of cold-rolled high manganese steel, you must align the furnace parameters with your specific mechanical requirements.

- If your primary focus is Impact Toughness: Prioritize a standard annealing cycle at 800°C to ensure complete recrystallization and a uniform austenitic structure for low-temperature durability.

- If your primary focus is Maximum Yield Strength: Utilize a process window that encourages the precipitation of kappa-carbides, ensuring the thermal field supports these nanostructures without inducing grain coarsening.

- If your primary focus is Dimensional Precision: Ensure the furnace controls specifically target the suppression of grain growth, maintaining a fine microstructure (approx. 10 μm) to predict post-forming behavior accurately.

Precise thermal regulation turns the furnace from a simple heating tool into a critical instrument for engineering molecular performance.

Summary Table:

| Process Parameter | Microstructural Effect | Mechanical Outcome |

|---|---|---|

| Recrystallization (800°C) | New strain-free grain growth | Stress relief & restored ductility |

| Short Holding Time (15m) | Fine-grained austenite formation | Balanced toughness & workability |

| Controlled Precipitation | Formation of κ-carbides/B2 phases | Ultra-high yield strength (up to 1241 MPa) |

| Overheating (≥ 950°C) | Excessive grain coarsening | Loss of yield strength & soft material |

Elevate Your Material Engineering with KINTEK

Don't let imprecise thermal cycles compromise your material integrity. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered for precise metallurgical control.

Whether you need to achieve ultra-high yield strength or exceptional low-temperature toughness, our expert R&D and manufacturing team can deliver customizable lab furnaces tailored to your unique research or production needs.

Ready to master your microstructure? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Lu, Shao-Lun, Max-Planck-Institut für Nachhaltige Materialien. Making High Mn Steel by Sustainable Ferromanganese Pre-alloy for Cryogenic Applications. DOI: 10.5281/zenodo.17520990

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What key process environments does a Molecular Beam Epitaxy (MBE) system provide? Optimize CaF2 Thin Film Growth

- How do high-temp furnaces influence LTO sintering? Optimize Lithium Titanate Performance via Precision Control

- What are the benefits of using a vacuum environment for RCM NSs? Master Material Preservation & Catalytic Performance

- What is the use of a laboratory furnace? Unlock Precise Material Transformation

- Why is a high flow rate of synthetic air maintained during magnetite oxidation? Ensure Accurate Kinetic Modeling

- What are the core technical advantages of a flash sintering system? Elevate KNN Ceramic Manufacturing Performance

- What is the use of furnace in laboratory? Unlock Precise High-Temperature Control for Material Transformations

- What is the function of industrial electric furnaces in EN AW-6082 preparation? Master Aluminum Heat Treatment