High-temperature laboratory furnaces act as the critical architect for Lithium Titanate (LTO) synthesis by establishing the precise thermodynamic conditions required for phase transformation. Through the rigorous control of heating rates, dwell times, and gas atmospheres, these instruments dictate the material's final crystal structure and electrochemical performance.

Core Takeaway By managing the thermal profile and atmospheric environment, furnaces ensure the complete solid-state reaction of precursors into a stable spinel structure. This process not only minimizes micro-defects but also fine-tunes the titanium valence states necessary for optimal electronic conductivity.

The Role of Thermodynamic Precision

Facilitating Crystal Growth

The primary function of a muffle or tube furnace in this context is to provide a precisely controlled thermodynamic environment.

This environment is essential for the precursors to overcome the activation energy barrier.

By maintaining a uniform thermal field, the furnace ensures the material undergoes a complete physical and chemical reaction, transforming from a raw precursor mix into the desired spinel structure.

Controlling Reaction Kinetics

Furnaces allow for the programming of specific heating rates and isothermal holding times.

These parameters dictate how quickly the solid-state reaction occurs.

If the heating is too rapid or the holding time too short, the phase transformation may be incomplete. Conversely, precise control allows for the full development of the crystal lattice.

Managing Thermal History

The cooling curve is just as critical as the heating phase.

Controlled cooling prevents thermal shock and stabilizes the newly formed crystal structure.

Advanced insulation in modern furnaces supports this by preventing temperature fluctuations, which protects the LTO from forming micro-defects during the calcination or sintering process.

Atmosphere Control and Electronic Conductivity

Regulating Oxygen Defects

Beyond temperature, the chemical atmosphere within the furnace plays a pivotal role in defining material properties.

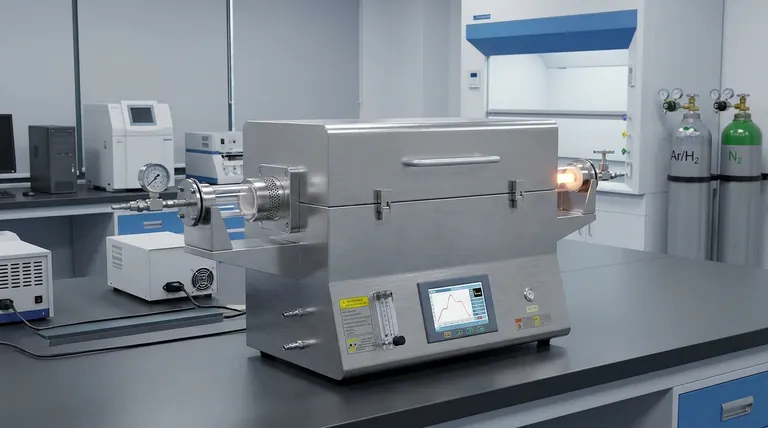

Tube furnaces and atmosphere-controlled muffle furnaces allow sintering in air, nitrogen, or hydrogen-argon mixtures.

The choice of gas directly influences the concentration of oxygen defects within the LTO lattice.

Tuning Titanium Valence States

The atmosphere determines the oxidation state of the titanium ions.

By adjusting the environment (e.g., using a reducing atmosphere), you can manipulate the titanium valence states.

This manipulation is the key lever for enhancing the electronic conductivity of the synthesized Lithium Titanate, a critical factor for battery performance.

Understanding the Trade-offs

Temperature Uniformity vs. Processing Speed

Achieving a perfectly uniform thermal field often requires slower ramp rates and longer dwell times.

While this ensures high-quality crystallization and minimizes micro-defects, it increases total energy consumption and processing time.

Atmosphere Sensitivity

Introducing complex atmospheres (like hydrogen-argon) significantly improves conductivity but introduces complexity.

It requires strict safety protocols and precise flow control.

Inconsistent atmosphere control can lead to heterogeneous material properties, where some particles are conductive and others remain insulating.

Making the Right Choice for Your Goal

To optimize your LTO synthesis, align your furnace parameters with your specific material requirements:

- If your primary focus is Structural Purity: Prioritize a furnace with excellent insulation and thermal uniformity to prevent micro-defects during the spinel transformation.

- If your primary focus is Electronic Conductivity: Select a tube furnace or atmosphere-controlled system capable of handling reducing gases to optimize titanium valence states.

Ultimately, the furnace is not just a heat source; it is a precision instrument for engineering the atomic-level defects and structure that define LTO performance.

Summary Table:

| Parameter | Influence on LTO Synthesis | Key Result |

|---|---|---|

| Thermal Uniformity | Facilitates crystal growth & phase transformation | Stable spinel structure with minimal defects |

| Heating/Dwell Time | Controls solid-state reaction kinetics | Complete precursors conversion & lattice development |

| Atmosphere Control | Regulates oxygen vacancies & Ti valence states | Enhanced electronic conductivity for battery performance |

| Cooling Profile | Manages thermal history & stress | Prevention of micro-defects and structural stabilization |

Maximize Your LTO Synthesis Precision with KINTEK

Unlock the full potential of your battery material research with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of solid-state sintering.

Whether you require precise atmosphere control to tune titanium valence states or superior thermal uniformity for structural purity, our high-temperature laboratory furnaces are fully customizable to your unique research needs. Ensure consistent, high-performance results for your Lithium Titanate (LTO) and other advanced materials.

Ready to elevate your lab's capabilities? Contact us today to discuss your custom furnace requirements!

References

- C. Julien, A. Mauger. Fabrication of Li4Ti5O12 (LTO) as Anode Material for Li-Ion Batteries. DOI: 10.3390/mi15030310

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is precise molar measurement of metal nitrates required during the preparation of high-entropy oxide precursor solutions? Ensure HEO Stability & Purity

- What is the function of a vacuum drying oven in cement testing? Preserve Sample Integrity for XRD/MIP Analysis

- How is Spark Plasma Sintering (SPS) equipment utilized in f-TEGs? Enhancing Alpha-Mg3Bi2 Interface Stability

- How does a Rapid Thermal Processing (RTP) system function? Optimize Nanowire Device Performance Today

- What is the purpose of performing a final annealing treatment? Optimize Your Heterojunction Device Performance

- Why is dual heat treatment required for SnO2 nanoparticles? Optimize Oxidation for Superior Performance

- What is the role of sintering in CsPbBr3-SiO2 preparation? Unlock Ultra-Stability with Precise Thermal Sealing

- What gas is used in a graphite furnace? A Guide to Argon vs. Nitrogen for Optimal Analysis