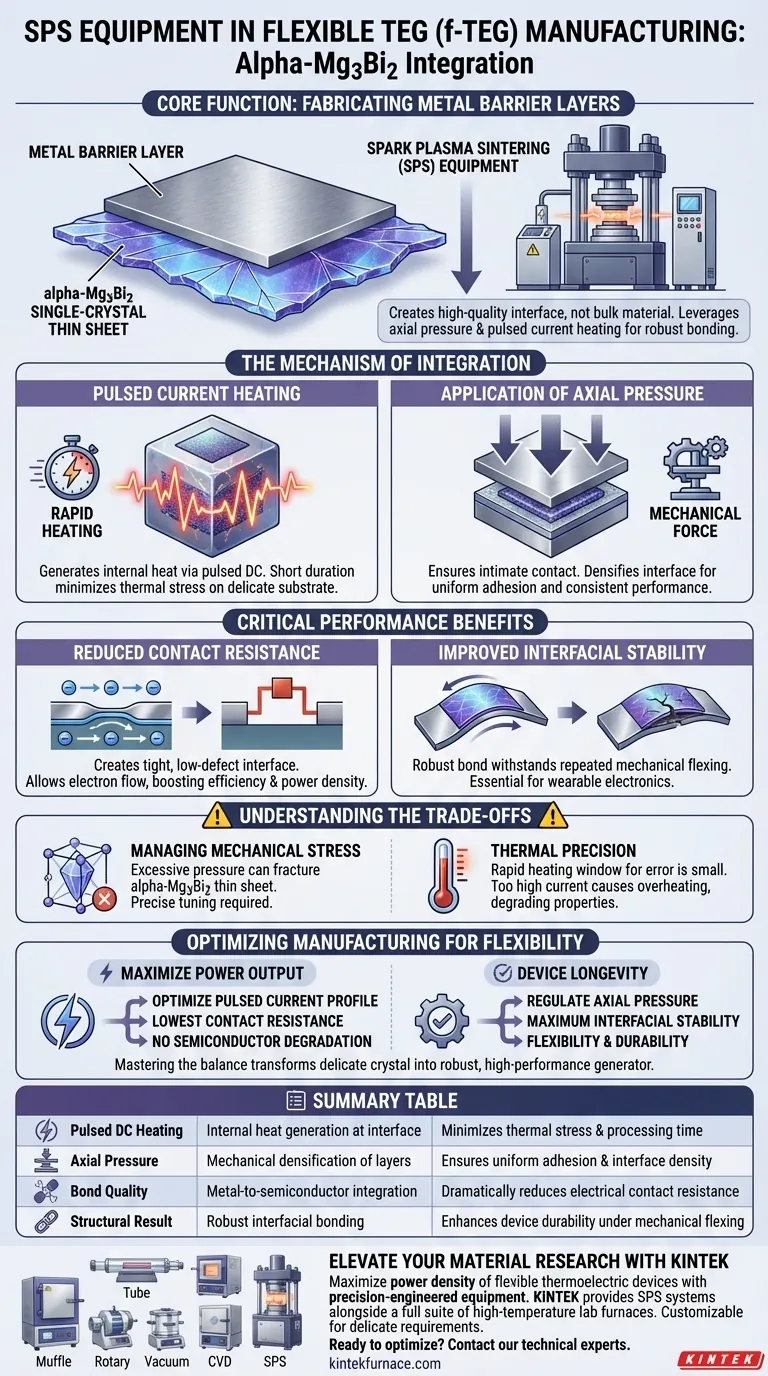

In the realm of flexible thermoelectric generator (f-TEG) manufacturing, Spark Plasma Sintering (SPS) equipment serves a highly specific and critical function: fabricating metal barrier layers directly onto the surfaces of alpha-Mg3Bi2 single-crystal thin sheets. Rather than synthesizing the bulk material itself, the equipment is leveraged to create a high-quality interface between the thermoelectric material and the conductive metal layer.

The core value of SPS in this context lies in its ability to apply axial pressure and pulsed current heating simultaneously. This allows for the rapid formation of a robust bond that significantly reduces contact resistance and enhances interfacial stability, which are prerequisites for high-power density flexible devices.

The Mechanism of Integration

Pulsed Current Heating

SPS distinguishes itself from conventional sintering methods by utilizing pulsed direct current. This generates heat internally within the die and the sample, rather than applying it from an external source.

This method allows for extremely rapid heating rates. Consequently, the metal barrier layer can be bonded to the alpha-Mg3Bi2 substrate in a short duration, minimizing thermal stress on the delicate thin sheet.

Application of Axial Pressure

Simultaneous with the heating, the equipment applies mechanical force. Axial pressure is exerted to ensure intimate contact between the metal barrier material and the thermoelectric sheet.

This pressure is vital for densifying the interface. It ensures that the metal layer adheres uniformly across the surface of the single-crystal sheet, which is essential for consistent electrical performance.

Critical Performance Benefits

Reducing Contact Resistance

The primary technical challenge in f-TEG manufacturing is electrical loss at connections. The SPS process creates a tight, low-defect interface between the metal and the alpha-Mg3Bi2.

This significantly reduces contact resistance. Lower resistance allows electrons to flow more freely across the junction, directly contributing to higher efficiency and power density in the final device.

Improving Interfacial Stability

Flexible devices undergo repeated mechanical stress during use. A weak bond will delaminate or crack, leading to device failure.

SPS achieves a robust bond that creates superior interfacial stability. This ensures the metal barrier remains intact even when the device is subjected to the flexing required of wearable or conformable electronics.

Understanding the Trade-offs

Managing Mechanical Stress

While axial pressure ensures a good bond, it presents a risk to the substrate. Alpha-Mg3Bi2 is utilized here as single-crystal thin sheets, which can be fragile.

Excessive or uneven pressure during the SPS process could fracture the crystal lattice. Process parameters must be tuned precisely to balance sufficient bonding force against the structural limits of the thin sheet.

Thermal Precision

The "short duration" of the process is a benefit, but also a constraint. Because the heating is rapid, the window for error is small.

If the pulsed current is too high, it could cause localized overheating or diffusion of the metal too deep into the thermoelectric material, potentially degrading its thermoelectric properties.

Optimizing Manufacturing for Flexibility

To effectively utilize SPS for alpha-Mg3Bi2 f-TEGs, you must align your processing parameters with your specific device requirements.

- If your primary focus is maximizing power output: Prioritize optimizing the pulsed current profile to achieve the lowest possible contact resistance without degrading the semiconductor.

- If your primary focus is device longevity: Focus on the regulation of axial pressure to ensure a bond that provides maximum interfacial stability against mechanical flexing.

By mastering the balance of pressure and pulsed heat, you transform a delicate single crystal into a robust, high-performance flexible generator.

Summary Table:

| Feature | Function in f-TEG Manufacturing | Key Benefit |

|---|---|---|

| Pulsed DC Heating | Internal heat generation at interface | Minimizes thermal stress & processing time |

| Axial Pressure | Mechanical densification of layers | Ensures uniform adhesion & interface density |

| Bond Quality | Metal-to-semiconductor integration | Dramatically reduces electrical contact resistance |

| Structural Result | Robust interfacial bonding | Enhances device durability under mechanical flexing |

Elevate Your Material Research with KINTEK

Maximize the power density of your flexible thermoelectric devices with precision-engineered equipment. KINTEK provides industry-leading Spark Plasma Sintering (SPS) systems alongside a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems.

Backed by expert R&D and manufacturing, our high-temperature lab furnaces are fully customizable to meet the delicate pressure and thermal requirements of materials like alpha-Mg3Bi2.

Ready to optimize your manufacturing process? Contact our technical experts today to find the perfect solution for your unique laboratory needs.

Visual Guide

References

- Mingyuan Hu, Jiaqing He. Helical dislocation-driven plasticity and flexible high-performance thermoelectric generator in α-Mg3Bi2 single crystals. DOI: 10.1038/s41467-024-55689-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are aluminum alloy castings subjected to high-temperature testing in an industrial blister oven? Reveal Defects

- Why is rapid water quenching necessary after thermal compression? Capture True Microstructures in Medium-Mn Steel

- What is the importance of transferring freshly deposited CuO films directly into a 125°C oven? Ensure Film Adhesion

- Why is a high-pressure reactor with a PTFE lining required for V-NbOPO4@rGO? Ensure Purity in Acidic Synthesis

- What are the core process advantages of using a microwave reactor? Maximize Speed & Efficiency in Lab Characterization

- What role does an industrial oven play in the pretreatment of oil palm shell for biochar? Ensure Peak Biomass Quality

- What is the function of an electric arc furnace in the preparation of aluminum-silicon model alloys? Expert Insights

- What role does a high-temperature furnace play in APTO for Vanadium to VO2? Precision Phase Transformation Explained