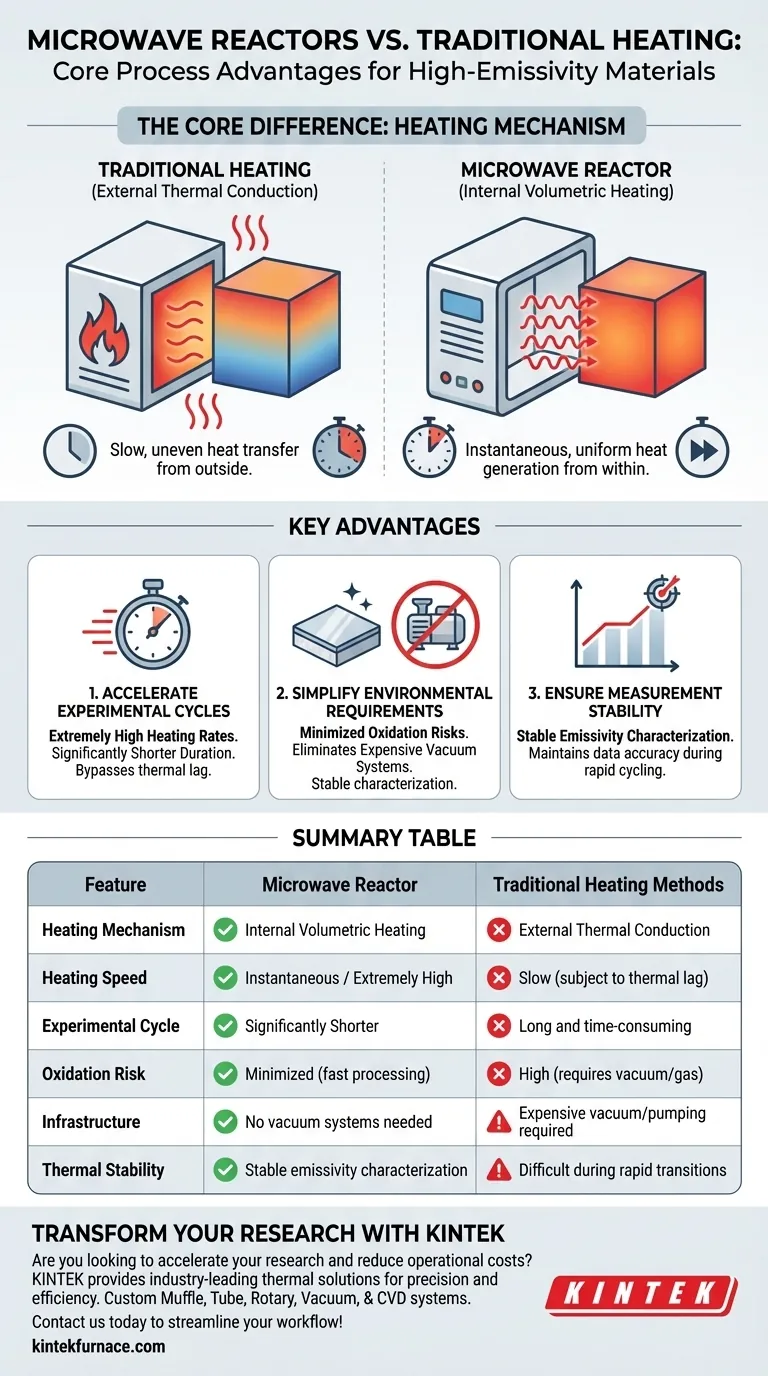

Microwave reactors offer a distinct advantage through internal volumetric heating, which generates heat from within the material rather than relying on external thermal conduction. This fundamental difference results in exceptionally fast heating rates, significantly shorter experimental cycles, and minimized material oxidation, all without requiring complex vacuum environments.

By utilizing internal energy transfer, microwave reactors enable rapid thermal cycling and stable emissivity characterization while eliminating the need for expensive protective vacuum systems typically required to prevent high-temperature oxidation.

The Mechanics of Volumetric Heating

Internal Energy Transfer

Traditional heating methods rely on heat transfer from the outside in, which can be slow and uneven. In contrast, a microwave reactor utilizes internal volumetric heating.

Direct Material Interaction

This mechanism allows energy to be transferred directly to the material's volume. Consequently, the material heats up uniformly and almost instantaneously compared to conventional methods.

Accelerating the Experimental Cycle

Achieving High Heating Rates

Because the energy transfer is internal, the system bypasses the thermal lag associated with conduction or convection. This results in extremely high heating rates.

Shortening Experiment Duration

The ability to reach target temperatures rapidly has a direct impact on process efficiency. It significantly shortens experimental cycles, allowing researchers to characterize materials in a fraction of the time required by traditional furnaces.

Simplifying Environmental Requirements

Reducing Oxidation Risks

High-temperature characterization often leads to material oxidation, which degrades the sample. The rapid nature of microwave heating minimizes the time the material is exposed to critical temperatures, naturally reducing the risk of oxidation.

Eliminating Vacuum Systems

Conventionally, preventing oxidation requires creating a vacuum environment, which demands expensive pumping systems. The microwave reactor's efficiency allows for stable characterization without the need for these expensive vacuum systems.

Ensuring Measurement Stability

Stable Emissivity Characterization

Despite the rapid changes in temperature, the process remains controlled. It allows for the stable characterization of emissivity changes, ensuring that data accuracy is maintained even during fast thermal cycling.

Understanding Operational Considerations

Material Compatibility

While highly effective, this process relies on the physics of microwave interaction. It is specifically beneficial for high-emissivity materials capable of coupling effectively with microwave energy to achieve volumetric heating.

Making the Right Choice for Your Goal

To determine if a microwave reactor is the optimal tool for your characterization needs, consider your specific constraints:

- If your primary focus is process speed: Leverage the high heating rates to drastically shorten your experimental cycles and increase throughput.

- If your primary focus is cost reduction: Utilize the inherent oxidation resistance to bypass the capital and maintenance costs of high-vacuum systems.

- If your primary focus is data integrity: Rely on the system’s ability to provide stable emissivity characterization during rapid thermal changes.

Microwave reactors provide a streamlined, cost-effective pathway to high-temperature characterization by substituting complex environmental controls with efficient, volumetric energy transfer.

Summary Table:

| Feature | Microwave Reactor | Traditional Heating Methods |

|---|---|---|

| Heating Mechanism | Internal Volumetric Heating | External Thermal Conduction |

| Heating Speed | Instantaneous / Extremely High | Slow (subject to thermal lag) |

| Experimental Cycle | Significantly Shorter | Long and time-consuming |

| Oxidation Risk | Minimized (fast processing) | High (requires vacuum/gas) |

| Infrastructure | No vacuum systems needed | Expensive vacuum/pumping required |

| Thermal Stability | Stable emissivity characterization | Difficult during rapid transitions |

Transform Your Material Characterization with KINTEK

Are you looking to accelerate your research and reduce operational costs? KINTEK provides industry-leading thermal solutions designed for precision and efficiency. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature lab furnaces—all fully customizable to your unique characterization needs.

Don't let traditional heating bottlenecks slow down your innovation. Contact us today to discover how our advanced heating technology can streamline your workflow and deliver stable, high-accuracy results for your high-emissivity materials.

Visual Guide

References

- Gloria Cosoli, Gian Marco Revel. A Measurement Approach for Characterizing Temperature-Related Emissivity Variability in High-Emissivity Materials. DOI: 10.3390/s25020487

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What is the significance of using an Annealing Furnace in gas sensors? Enhance Stability and Sensitivity

- What is the function of a 1% CO-99% Argon gas mixture? Protect Phase Equilibrium Experiments from Oxidation

- Why is a precision temperature control system essential for wood carbonization? Achieve Perfect Shape Fidelity

- What is a sintering furnace used for? Fuse Powders into Dense, High-Performance Parts

- Why is it necessary to thoroughly dry biomass raw materials before starting a pyrolysis experiment? Improve Yields

- Why is precise sample loading critical in CO2 capture experiments? Avoid Bed Effects and Ensure Data Integrity

- What role does an ultrafast Joule heating device play in the synthesis of heterostructure nanocatalysts?

- Why use 10% Carbon Monoxide in black liquor pyrolysis? Prevent sodium volatilization for superior char quality.