At its core, a sintering furnace is a specialized oven used to transform powdered materials into a solid, dense mass using high heat. It accomplishes this through a process called sintering, where the material is heated to a temperature below its melting point, causing the individual particles to fuse and bond together.

The true value of a sintering furnace lies not just in heating, but in its ability to precisely control the thermal and atmospheric environment. This control allows manufacturers to create strong, complex components from materials—like high-performance metals and ceramics—that are otherwise difficult to shape.

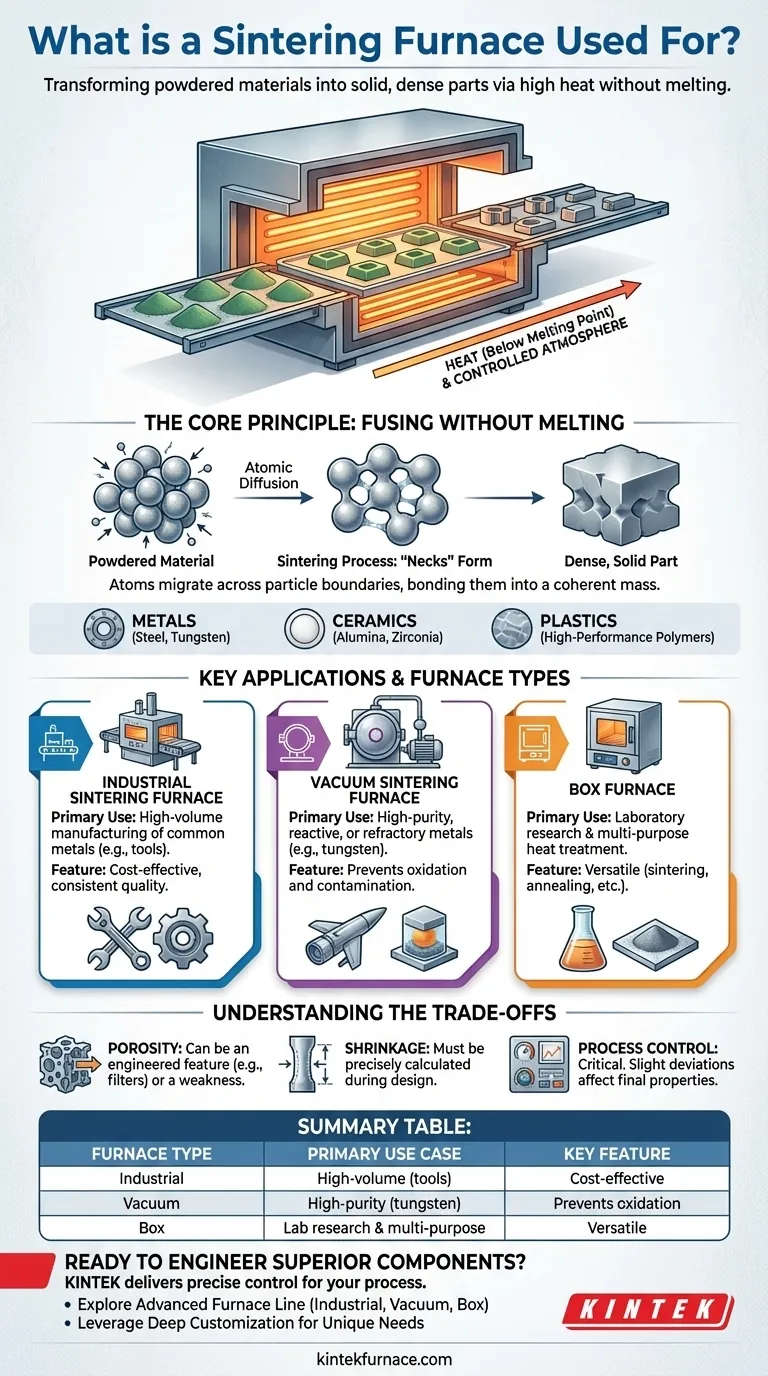

The Core Principle: Fusing Without Melting

How Sintering Works

Sintering is a process of atomic diffusion. When powdered material is heated, the atoms on the surfaces of adjacent particles become more mobile.

Under controlled temperature and sometimes pressure, these atoms migrate across the boundaries of the particles, creating "necks" that grow until the particles are fused into a coherent, solid piece.

The Goal: A Dense, Solid Part

Crucially, the material never becomes a liquid. The process compacts and bonds the powder into a solid structure that is nearly as dense as a part made by melting and casting.

This solid-state process is what makes sintering unique and essential for certain applications.

Materials That Can Be Sintered

Sintering is an incredibly versatile process used across many industries. Common materials include:

- Metals: Stainless steel, tungsten, molybdenum, and various alloys.

- Ceramics: Alumina, zirconia, and other technical ceramics.

- Plastics: Certain high-performance polymers.

Key Applications and Furnace Types

General Industrial Manufacturing

For common applications, a standard industrial sintering furnace is used to produce a wide range of parts.

These furnaces are workhorses for creating items like durable stainless-steel tools or the metal components in shotgun shells, where high volume and consistent quality are key.

High-Purity and Refractory Materials

A vacuum sintering furnace is a more specialized variant designed for advanced materials. By performing the heating process in a vacuum, it prevents oxidation and contamination.

This is critical for sintering reactive or refractory (high-melting-point) metals like tungsten and molybdenum, which are used in scientific research, aerospace, and military applications. The result is a purer, higher-performance final product.

Multi-Purpose Laboratory Use

A box furnace is a general-purpose oven often found in laboratories and research institutions. While it can be used for sintering, its primary function is often broader.

These furnaces are also used for other heat-treatment processes like annealing, tempering, and quenching. They are ideal for small-scale production, material testing, and research where versatility is more important than dedicated, high-volume sintering.

Understanding the Trade-offs

Porosity Cannot Be Ignored

Sintering almost always leaves some level of microscopic pores in the final part. While this can be a weakness, it can also be engineered as a feature, for example, in creating self-lubricating bearings or filters.

Shrinkage Must Be Calculated

As the powder compacts and fuses, the overall part will shrink. This shrinkage must be precisely calculated and accounted for during the initial design of the mold and the "green" (unsintered) part to achieve the final desired dimensions.

Process Control is Everything

The final properties of a sintered part are extremely sensitive to temperature, time, and atmosphere. A slight deviation can lead to a weak or dimensionally inaccurate component, making process control the most critical factor for success.

Making the Right Choice for Your Goal

The type of furnace you need is dictated entirely by your material and desired outcome.

- If your primary focus is producing high-purity, reactive, or refractory metal parts: A vacuum sintering furnace is non-negotiable to prevent oxidation and ensure material integrity.

- If your primary focus is cost-effective, high-volume manufacturing of common metals: A standard industrial sintering furnace is the correct tool for the job.

- If your primary focus is laboratory research or multi-purpose heat treatment: A versatile box furnace that includes a sintering capability provides the flexibility needed for experimentation.

By mastering this solid-state fusion process, you can engineer high-performance components that are often impossible to create through traditional melting and casting.

Summary Table:

| Furnace Type | Primary Use Case | Key Feature |

|---|---|---|

| Industrial Sintering Furnace | High-volume manufacturing of common metals (e.g., tools) | Cost-effective, consistent quality |

| Vacuum Sintering Furnace | High-purity, reactive, or refractory metals (e.g., tungsten) | Prevents oxidation and contamination |

| Box Furnace | Laboratory research & multi-purpose heat treatment | Versatile (sintering, annealing, etc.) |

Ready to Engineer Superior Components with Precision Sintering?

Whether you are developing advanced materials in a research lab or manufacturing high-performance metal parts, the right furnace is critical to your success. KINTEK's expertise in high-temperature thermal solutions delivers the precise control your process demands.

- Explore Our Advanced Furnace Line: From robust Industrial and Vacuum Sintering Furnaces to versatile Box Furnaces, we have the solution for your material and application.

- Leverage Deep Customization: Our strong R&D and in-house manufacturing capabilities allow us to tailor furnace systems to your unique experimental or production requirements.

Let's discuss how a KINTEK sintering furnace can become the cornerstone of your manufacturing or research. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance