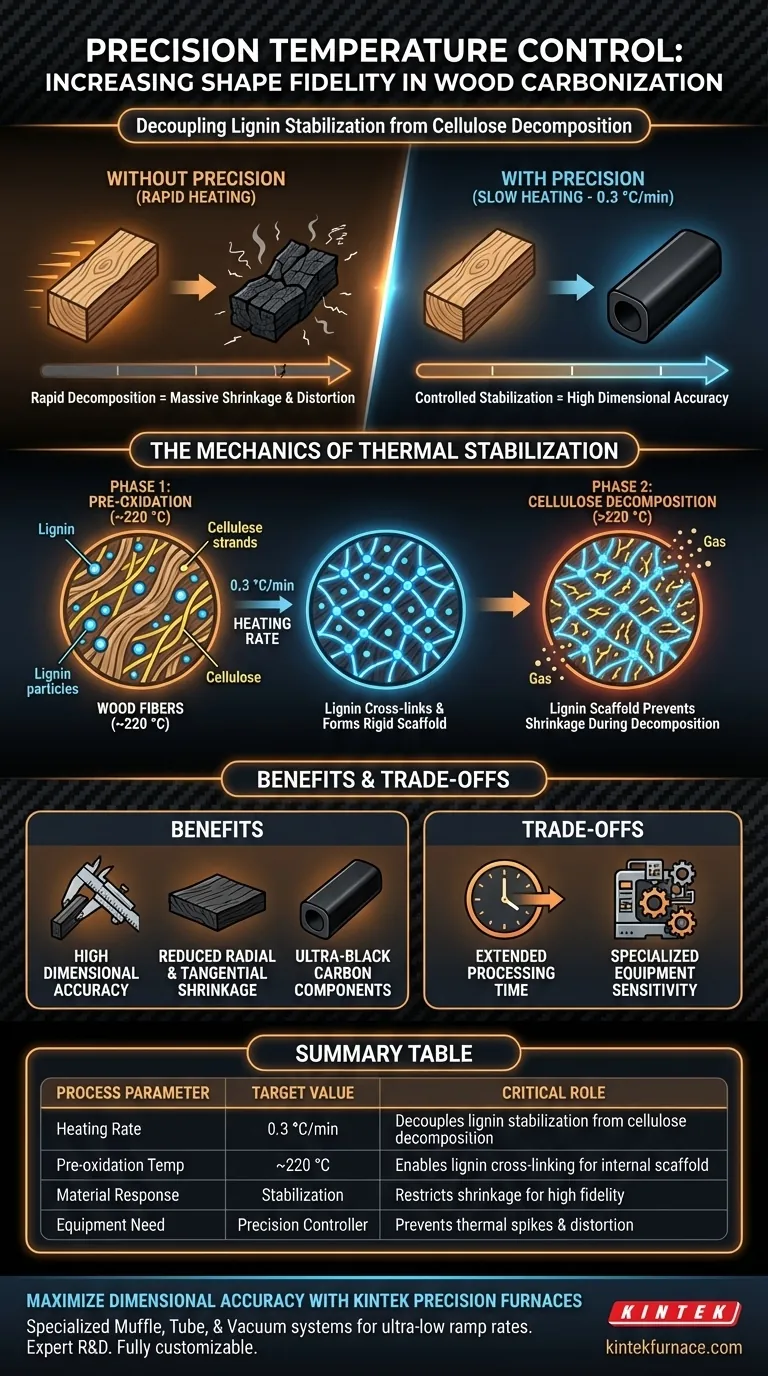

A precision temperature control system is essential because it decouples the stabilization of lignin from the decomposition of cellulose. By maintaining a specific, low heating rate (approximately 0.3 °C/min) up to 220 °C, the system allows lignin to cross-link and reinforce the wood structure. This internal reinforcement prevents significant shrinkage and warping when the cellulose eventually decomposes at higher temperatures, ensuring the final carbon component retains its original shape.

Core Insight: The secret to shape fidelity lies in timing: slow heating creates a protective lignin skeleton before the main wood structure degrades. Without this precise thermal stabilization, rapid decomposition causes massive shrinkage and structural distortion.

The Mechanics of Thermal Stabilization

The Role of Pre-Oxidation

To achieve high dimensional accuracy, the wood must undergo a "pre-oxidation" phase rather than immediate carbonization.

This occurs at approximately 220 °C. A precision control system ensures the material reaches and holds this temperature accurately without overshooting, which is critical for the chemical changes required.

Lignin as a Structural Reinforcement

At this specific temperature and heating rate, the lignin particles within the wood undergo a process of partial graphitization or cross-linking.

This transformation effectively turns the lignin into a rigid coating. This coating acts as a stabilizing agent for the surrounding material.

Timing Cellulose Decomposition

The primary reason for the specific heating rate of 0.3 °C/min is to ensure the lignin stabilizes before the cellulose skeleton begins to decompose.

If the temperature rises too fast, the cellulose breaks down before the lignin has formed its protective network.

By prioritizing the lignin cross-linking first, the wood develops an internal scaffold that holds the material together during the more destructive phases of carbonization.

Managing Shrinkage and Dimensional Accuracy

Reducing Radial and Tangential Shrinkage

Wood naturally shrinks anisotropically (differently in different directions) when heated, which typically leads to warping.

The stabilized lignin coating significantly restricts both radial and tangential shrinkage. This uniformity is what allows the final product to match the geometry of the original wood.

Achieving Ultra-Black Carbon Components

The ultimate goal of this process is often the creation of ultra-black carbon components.

These components require precise surface fidelity to function correctly. The precision heating profile ensures that the final carbonized structure is not only black but also geometrically faithful to the original design.

Understanding the Trade-offs

The Cost of Processing Time

The primary trade-off of this method is the significant time investment required.

A heating rate of 0.3 °C/min is extremely slow. This extends the production cycle considerably compared to standard industrial carbonization methods.

Equipment Sensitivity

Achieving such a specific, low ramp rate requires sophisticated thermal controllers.

Standard ovens often fluctuate too wildly to maintain a consistent 0.3 °C/min rise. Therefore, specialized equipment is necessary to prevent thermal spikes that could ruin the stabilization phase.

Making the Right Choice for Your Goal

To apply these principles effectively, consider your specific manufacturing priorities:

- If your primary focus is Shape Fidelity: Strictly adhere to the 0.3 °C/min heating rate up to 220 °C to ensure the lignin skeleton fully forms before cellulose degrades.

- If your primary focus is Production Speed: Recognize that increasing the heating rate will bypass the stabilization phase, resulting in unpredictable shrinkage and warped components.

Precision control is not just about temperature; it is about synchronizing chemical reactions to preserve the structural integrity of the material.

Summary Table:

| Process Parameter | Target Value | Critical Role in Carbonization |

|---|---|---|

| Heating Rate | 0.3 °C/min | Decouples lignin stabilization from cellulose decomposition |

| Pre-oxidation Temp | ~220 °C | Enables lignin cross-linking to form a rigid internal scaffold |

| Material Response | Stabilization | Restricts radial and tangential shrinkage for high fidelity |

| Equipment Need | Precision Controller | Prevents thermal spikes that cause structural distortion |

Maximize Dimensional Accuracy with KINTEK Precision Furnaces

Don't let unpredictable shrinkage ruin your high-fidelity carbon components. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, and Vacuum systems designed to maintain the ultra-low ramp rates (0.3 °C/min) essential for successful wood stabilization and carbonization. Whether you need a standard setup or a fully customizable high-temperature furnace, our team ensures your lab is equipped for excellence. Contact KINTEK today to discuss your unique thermal processing needs!

Visual Guide

References

- Bin Zhao, Bruno D. Mattos. Wood Reconfiguration Enables Broadband Blackbody in Large‐Area, Modular, Optically Welded Carbon Constructs. DOI: 10.1002/adfm.202506820

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the main types of sintering methods for metals, ceramics, and refractory intermetallic compounds powders? Optimize Your Material Processing

- What are the core advantages of using a microwave hydrothermal synthesis system? Rapid & Uniform CNS Production

- What advantages does a vacuum oven offer over a standard oven for V2CTx MXene films? Protect Your Material Quality

- What role does a high-temperature sintering furnace play in lead-free piezoelectric ceramics? Optimizing Performance

- What is Skin Depth and how does it affect induction heating? Master Frequency Control for Precise Heat

- Why is a low-temperature annealing treatment necessary for porous gold microspheres? Ensure Structural Integrity

- Why is a cycle of secondary grinding and re-sintering employed in BiCuSeO preparation? Achieve Peak Material Density

- How does a precision pressure-controlled oxidation device increase carbon chain yield? Optimize Your Annealing Process