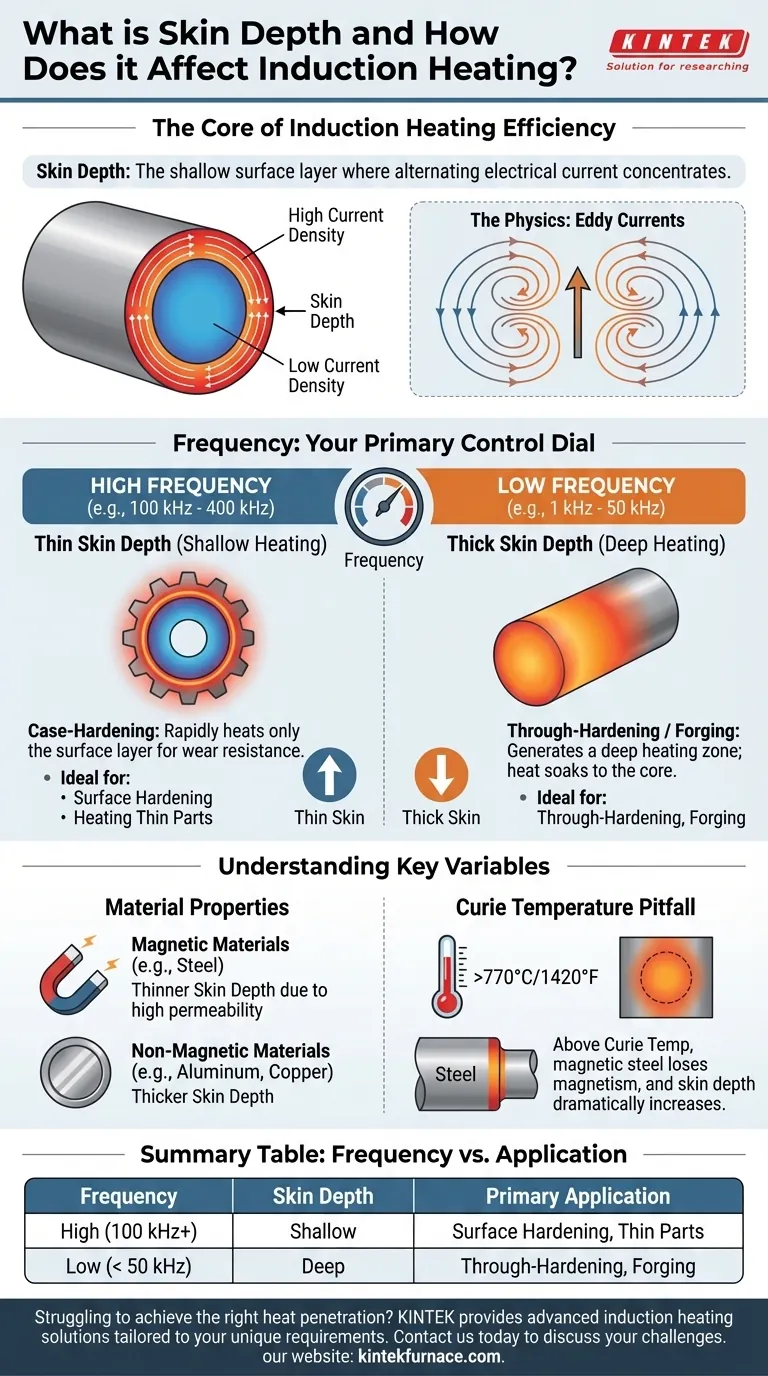

At its core, skin depth is the shallow layer on a conductor's surface where an alternating electrical current concentrates. In induction heating, this phenomenon, known as the "skin effect," is not a limitation but the primary mechanism for success. It allows you to focus immense heating power precisely where you need it, turning electrical energy into thermal energy with exceptional speed and control.

The central challenge in induction heating isn't just knowing what skin depth is, but understanding how to control it. The frequency of the alternating current is your primary tool for dictating exactly where and how fast your part heats up, determining the success of your entire process.

The Physics Behind the Skin Effect

To use skin depth effectively, you must first understand why it occurs. It is a fundamental property of alternating currents in conductors.

How Alternating Current Stays on the Surface

An alternating current flowing through a conductor generates a changing magnetic field around and within it. This changing field, in turn, induces secondary currents, known as eddy currents, inside the conductor itself.

These eddy currents swirl in directions that oppose the main current flow in the center of theconductor, effectively canceling it out. However, they reinforce the main current at the surface. The result is a net current flow that is highly concentrated in a thin layer, or "skin," on the conductor's surface.

Why It's Called a "Depth"

The current doesn't stop at a hard boundary. Its density is highest at the surface and decays exponentially toward the center of the part.

The technical skin depth is the distance from the surface where the current density has fallen to approximately 37% (or 1/e) of its value at the surface. Critically, about 86% of the total heat generated by the current is produced within this single layer, making it the most important region for heating.

The Key Relationship: Frequency is Your Control Dial

The single most important factor you can control is frequency. The skin depth is inversely proportional to the square root of the frequency.

This relationship is simple and powerful:

- High Frequency = Thin Skin Depth (Shallow Heating)

- Low Frequency = Thick Skin Depth (Deep Heating)

How Skin Depth Governs Induction Heating

Understanding this principle allows you to tailor the heating process to your specific goal, whether it's hardening a tiny surface layer or heating a massive billet for forging.

Concentrating Heat for High Efficiency

By forcing the current into a very thin skin, you dramatically increase the current density. This concentration leads to rapid and intense resistive heating (I²R losses) precisely at the part's surface.

This is why induction is so efficient. Instead of heating the air around a part and waiting for that heat to transfer, induction generates the heat directly inside the material where it is needed.

Case-Hardening vs. Through-Hardening

The most common application of this principle is in heat treating.

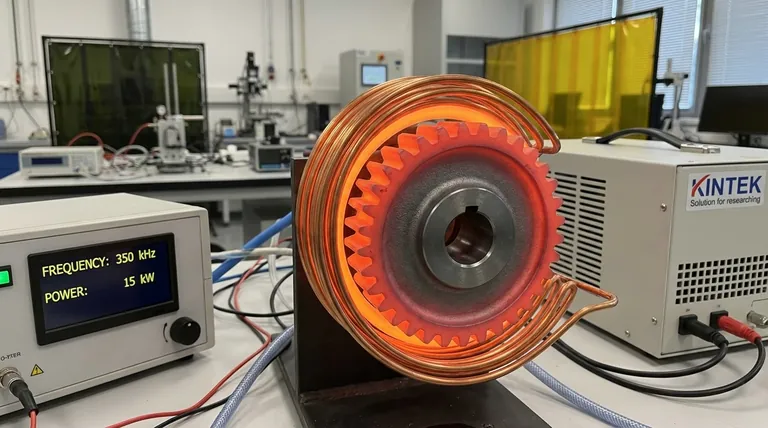

For case-hardening, where you need a hard, wear-resistant surface while keeping the core ductile, you use a high frequency (e.g., 100 kHz to 400 kHz). This creates a very thin skin depth, rapidly heating only the surface layer before the heat has time to conduct deeper into the part.

For through-hardening or pre-heating for forging, you need to heat the entire cross-section of the part. Here, you use a low frequency (e.g., 1 kHz to 50 kHz). This generates a deeper heating zone and provides more time for the heat to "soak" via thermal conduction to the component's core.

Matching Frequency to Part Geometry

To heat a part effectively, the skin depth should be significantly smaller than the part's thickness or radius.

If the skin depth is too large relative to the part's thickness, the magnetic fields induced from opposite sides can meet in the middle and cancel each other out. This dramatically reduces the induced current and leads to very inefficient heating.

Understanding the Trade-offs and Key Variables

While frequency is your primary control, it doesn't operate in a vacuum. Material properties also play a critical role in the outcome.

The Role of Material Properties

The formula for skin depth also includes the material's electrical resistivity and magnetic permeability.

Magnetic materials like steel have a very high magnetic permeability, which results in a much thinner skin depth compared to non-magnetic materials like aluminum or copper at the same frequency.

The Curie Temperature Pitfall

When magnetic steel is heated above its Curie temperature (approximately 770°C or 1420°F), it loses its magnetic properties.

This causes its magnetic permeability to drop dramatically, which in turn causes the skin depth to suddenly increase. Your induction system must be able to account for this change in load to continue heating the part effectively.

The Risk of Inefficient Coupling

You must ensure the energy from your induction coil is properly transferred to the workpiece. If the frequency is too low for a small part, or the part is positioned too far from the coil, the magnetic field can "pass through" without inducing sufficient current. This results in poor coupling and wasted energy.

Making the Right Choice for Your Application

Selecting the correct frequency is a function of your material, part size, and desired heating outcome. Use these principles as your guide.

- If your primary focus is surface hardening or heating thin parts: Use a high frequency (100 kHz+) to create a shallow skin depth for rapid, localized heating.

- If your primary focus is heating a large part all the way through for forging or through-hardening: Use a lower frequency (< 50 kHz) to achieve deeper heat penetration and allow time for thermal conduction to the core.

- If your primary focus is heating magnetic steel parts: Be prepared for the skin depth to increase as the material passes its Curie temperature, which will alter the heating characteristics mid-process.

Ultimately, mastering skin depth is about selecting the right frequency to deliver thermal energy with absolute precision and efficiency.

Summary Table:

| Frequency | Skin Depth | Primary Application |

|---|---|---|

| High (100 kHz+) | Shallow | Surface Hardening, Thin Parts |

| Low (< 50 kHz) | Deep | Through-Hardening, Forging |

Struggling to achieve the right heat penetration in your induction heating process? The key lies in precisely controlling the skin depth through frequency selection. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced induction heating solutions tailored to your unique requirements. Whether you need high-frequency systems for precise case-hardening or low-frequency power supplies for deep through-heating, our expertise ensures optimal efficiency and results.

Contact us today (#ContactForm) to discuss how our customized induction heating systems can solve your specific thermal processing challenges.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency