Microwave hydrothermal synthesis systems offer a distinct technological edge in the production of carbon nanospheres (CNSs) by fundamentally changing how heat is applied to the reaction. By utilizing microwave radiation to induce molecular polar rotation, the system generates heat directly within the liquid rather than relying on conduction from an external source. This results in a production process that is significantly faster and more uniform than traditional methods.

Core Takeaway The primary advantage of microwave synthesis lies in its mechanism of direct energy transfer; by heating the reaction liquid internally via molecular interaction, it eliminates thermal gradients and reduces reaction times from hours to minutes, ensuring superior consistency in the final nanomaterials.

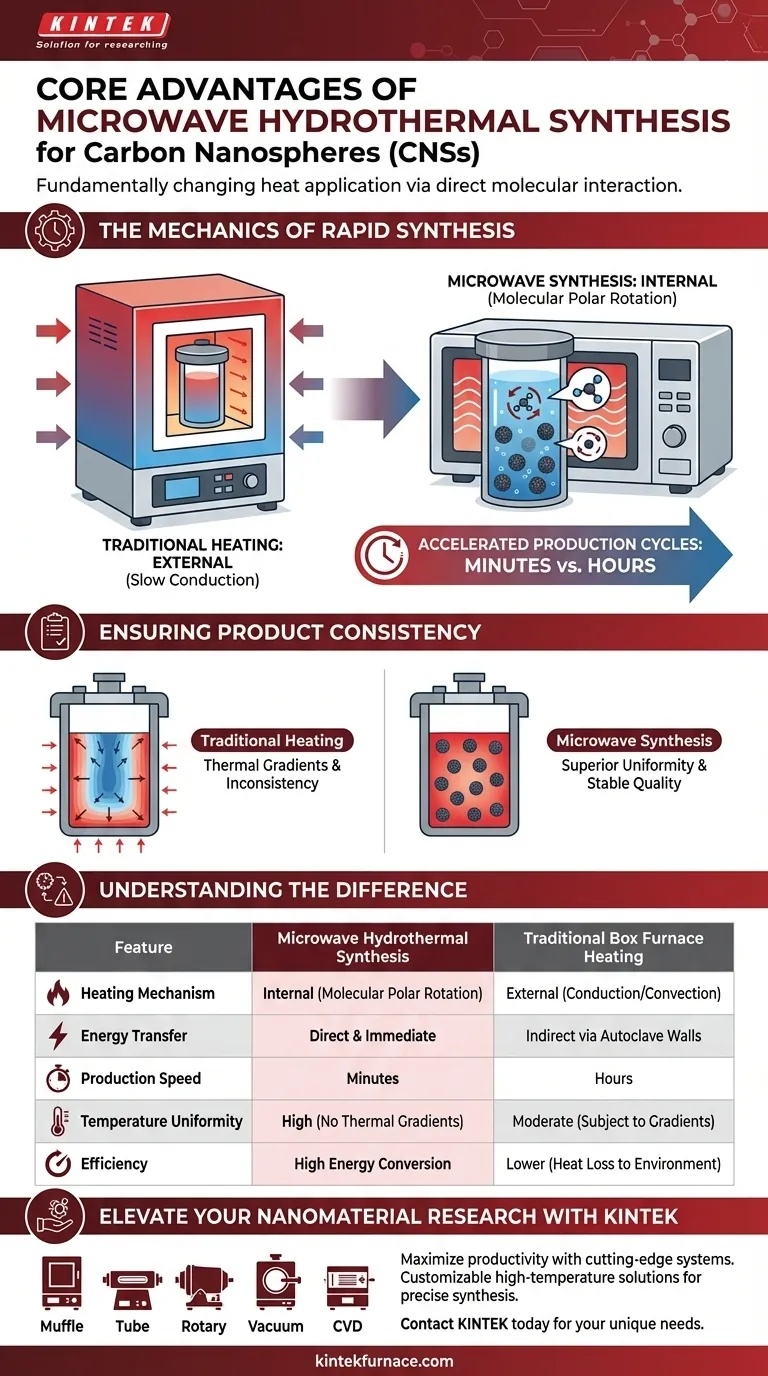

The Mechanics of Rapid Synthesis

Direct Energy Transfer

Unlike conventional methods that heat a vessel from the outside, microwave systems utilize microwave radiation.

This radiation acts directly on the reaction liquid through a process known as molecular polar rotation. The energy is converted immediately into heat at the molecular level, ensuring high energy conversion efficiency.

Accelerated Production Cycles

The most immediate operational benefit is speed.

Because the heating mechanism is direct and internal, the reaction system reaches the target temperature much more rapidly. This allows synthesis reactions to be completed within minutes, significantly shortening the overall production cycle compared to traditional hydrothermal methods.

Ensuring Product Consistency

Eliminating Temperature Gradients

Traditional heating often creates uneven temperature zones—hotter near the walls, cooler in the center.

Microwave synthesis heats the entire volume of the liquid evenly. This superior heating uniformity prevents the formation of temperature gradients that typically lead to inconsistencies in the final product.

Stabilizing Quality

In the production of carbon nanospheres, uniformity is critical.

By removing thermal fluctuations, the microwave system effectively prevents product quality fluctuations. This ensures that the structural and chemical properties of the CNSs remain consistent throughout the batch.

Understanding the Difference: Microwave vs. Traditional Heating

The Limits of External Heating

To appreciate the value of the microwave system, it is helpful to understand the alternative: the industrial-grade laboratory box furnace.

As noted in standard hydrothermal processes, a box furnace acts as an external heat source to warm an autoclave. While this method provides a stable thermal field (e.g., maintaining 150 °C), it relies on conductive heating.

Efficiency Comparison

The box furnace method is inherently slower because heat must travel from the furnace air, through the autoclave walls, and finally into the solution.

While effective for specific crystallization processes (such as forming inverse spinel structures with Cobalt and Zirconium), this external approach cannot match the rapid heating rates or the energy efficiency of the direct microwave interaction used for CNS production.

Making the Right Choice for Your Goal

When selecting a synthesis methodology for carbon nanospheres, align your choice with your production priorities:

- If your primary focus is Production Speed: Leverage microwave synthesis to reduce reaction times to minutes through direct molecular heating.

- If your primary focus is Product Uniformity: Use microwave systems to eliminate temperature gradients and ensure every nanosphere is subjected to the exact same thermal conditions.

By adopting microwave hydrothermal synthesis, you move from a passive heating process to an active, molecular-level manufacturing strategy.

Summary Table:

| Feature | Microwave Hydrothermal Synthesis | Traditional Box Furnace Heating |

|---|---|---|

| Heating Mechanism | Internal (Molecular Polar Rotation) | External (Conduction/Convection) |

| Energy Transfer | Direct & Immediate | Indirect via Autoclave Walls |

| Production Speed | Minutes | Hours |

| Temperature Uniformity | High (No Thermal Gradients) | Moderate (Subject to Gradients) |

| Efficiency | High Energy Conversion | Lower (Heat Loss to Environment) |

Elevate Your Nanomaterial Research with KINTEK

Maximize your lab's productivity with our cutting-edge microwave hydrothermal systems. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to meet the rigorous demands of advanced nanomaterial synthesis.

Whether you are producing carbon nanospheres or complex oxide structures, our high-temperature solutions ensure the thermal precision your work deserves. Contact us today to find the perfect customizable furnace for your unique needs and experience the KINTEK advantage in precision and performance.

Visual Guide

References

- Kaihe Lv, Jinsheng Sun. Microwave-Assisted Synthesis of Carbon Nanospheres and Their Application as Plugging Agents for Oil-Based Drilling Fluids. DOI: 10.3390/molecules30030463

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do sputtering systems and lift-off processes interact? Master Micro-Device Fabrication for ST-FMR Measurements

- What are the advantages of using a vacuum drying oven for MnMgPO4@C3N4? Preserving Photocatalyst Integrity

- How do high-pressure reaction environments facilitate the solvothermal synthesis of Ag2Se? Precision Phase Control

- What is the role of industrial drying ovens equipped with fan systems in the convective hot air drying of fruit materials? Boost Quality & Preserve Nutrients

- Why is precision constant temperature control required during the hardening stage of geopolymer mortar? Guide to Success

- What is tempering, and when is it used? Optimize Metal Toughness and Durability

- What is the function of 0.5 mbar nitrogen in sintering? Prevent Chromium Loss for Stronger Cermets

- How does the pre-oxidation process affect high-temperature alloys? Enhancing Surface Integrity for Steam Cracking