Industrial drying ovens equipped with fan systems function as the primary engine for forced convection, ensuring the uniform and efficient removal of moisture from fruit materials. By generating a consistent cycle of heated air, these systems eliminate cold spots and prevent localized moisture buildup. This controlled environment allows for dehydration at lower temperatures, which is essential for maintaining the physical and chemical integrity of the fruit.

The core role of fan-equipped ovens is to provide a stable, low-temperature environment through forced convection. This balance enables efficient moisture extraction while protecting the fruit’s delicate bioactive profile from thermal damage.

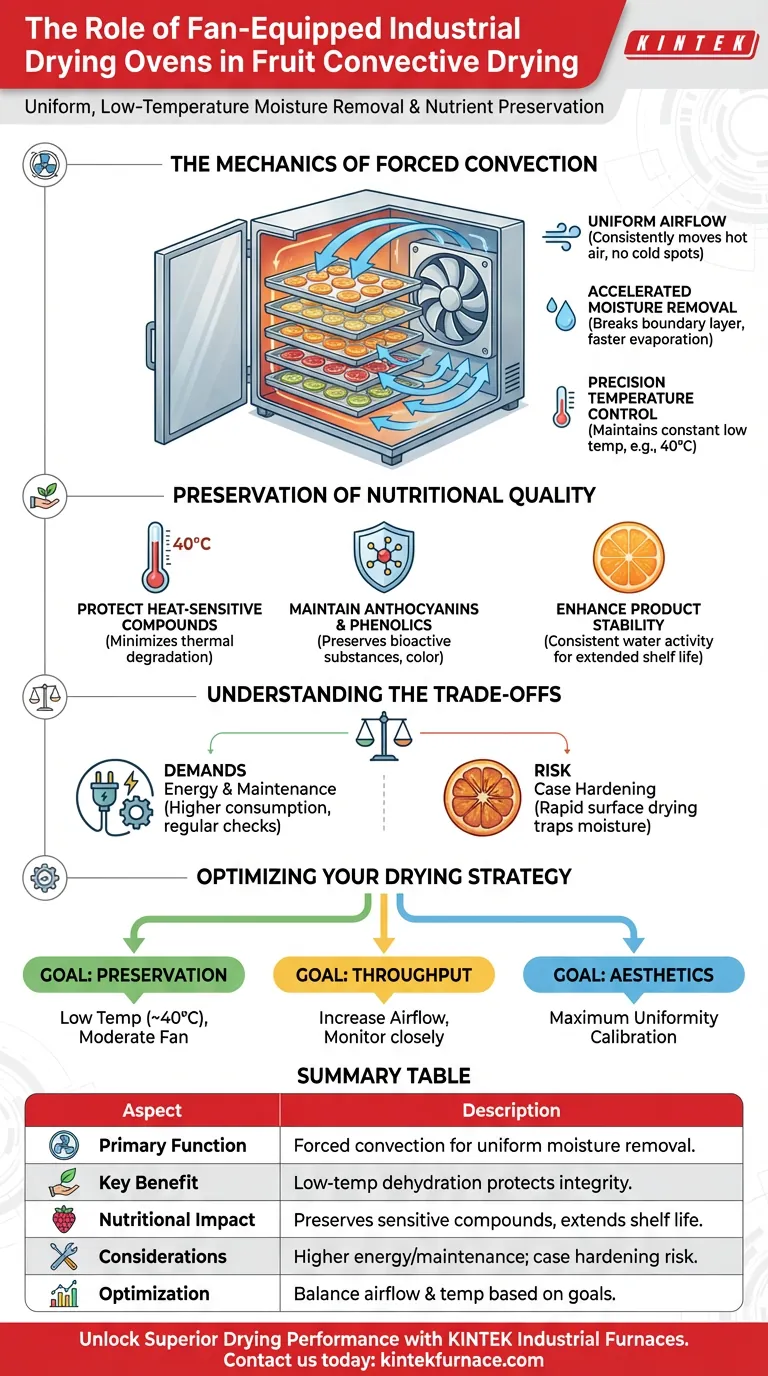

The Mechanics of Forced Convection

Achieving Uniform Airflow

The integration of fan systems transforms a static heating chamber into a dynamic forced convection environment. This ensures that hot air moves consistently across the entire surface of the fruit material, such as a puree, rather than relying on natural air movement.

Accelerating Moisture Removal

Consistent airflow effectively breaks down the boundary layer of saturated air that forms on the fruit's surface. This allows for a much faster and more predictable evaporation rate, facilitating the continuous migration of water from the center of the material to its exterior.

Precision Temperature Control

Fan systems allow the oven to maintain a constant temperature—often as low as 40°C—throughout the drying cycle. This precision prevents temperature spikes that could lead to uneven drying or scorched edges on the fruit.

Preservation of Nutritional Quality

Protecting Heat-Sensitive Compounds

Many fruits contain delicate bioactive substances that break down quickly under high heat. Because fan-driven ovens can dry effectively at lower temperatures, they minimize the thermal degradation of these valuable nutrients.

Maintaining Anthocyanins and Phenolics

Specific antioxidants, such as anthocyanins and phenolic substances, are highly susceptible to heat damage. The gentle, controlled environment of a fan-equipped oven ensures these compounds remain intact, preserving both the fruit's nutritional value and its natural color.

Enhancing Product Stability

By removing moisture uniformly, these ovens ensure the final product has a consistent water activity level. This uniformity is critical for extending shelf life and preventing microbial growth without the need for excessive heat.

Understanding the Trade-offs

Energy and Maintenance Demands

While fan systems significantly improve product quality, they increase the overall energy consumption of the drying process. Additionally, the mechanical nature of fans requires a regular maintenance schedule to prevent motor failure or airflow obstructions.

The Risk of Case Hardening

If the fan speed is set too high, the surface of the fruit may dry and harden too quickly, a phenomenon known as case hardening. This creates a barrier that traps moisture inside the product, potentially leading to internal spoilage despite a dry exterior.

Optimizing Your Drying Strategy

Selecting the right parameters for your fan-driven drying system depends on your specific product goals and the sensitivity of your raw materials.

- If your primary focus is nutritional preservation: Use a low-temperature setting (approximately 40°C) with moderate fan speeds to protect sensitive anthocyanins and phenolics.

- If your primary focus is production throughput: Increase the airflow velocity to accelerate evaporation, but monitor the product closely for signs of surface hardening.

- If your primary focus is color and aesthetics: Ensure the fan system is calibrated for maximum uniformity to prevent localized "hot spots" that cause browning or discoloration.

Mastering the balance between airflow velocity and temperature is the key to producing high-quality dried fruit that retains its natural health benefits.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Forced convection for uniform, efficient moisture removal in fruit drying. |

| Key Benefit | Enables dehydration at lower temperatures (e.g., 40°C) to protect product integrity. |

| Nutritional Impact | Preserves heat-sensitive compounds (anthocyanins, phenolics) and extends shelf life. |

| Considerations | Higher energy/maintenance demands; risk of case hardening with improper settings. |

| Optimization | Balance airflow and temperature based on specific goals: preservation, throughput, or aesthetics. |

Unlock superior drying performance for your fruit materials. Our KINTEK industrial furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems, are engineered with expert R&D and manufacturing to meet your specific needs. From precise temperature control to uniform drying, we deliver customizable high-temp solutions that ensure optimal product quality and nutrient preservation. Ready to enhance your process? Contact us today to discuss your industrial drying oven requirements!

Visual Guide

References

- Recep Güneş. A Study on Quality Properties of Blackthorn (<i>Prunus spinosa</i> L.) Fruit Powder Obtained by Different Drying Treatments. DOI: 10.1051/bioconf/20248501011

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the role of a high-temperature stainless steel autoclave in the synthesis of Copper Ferrite (CuFe2O4)?

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- What is the importance of preheating the mold? Master Thermal Control for Aluminum Matrix Composites

- What function does a water quenching tank serve in Ni-Ti alloy heat treatment? Lock in Superelasticity & Shape Memory

- How do laboratory high-temperature resistance furnaces simulate industrial production processes for 01YUT steel?

- Why is a vacuum drying oven required for the pretreatment of modified zeolite? Preserve Pore Integrity for CO2 Capture

- What is the purpose of performing a final annealing treatment? Optimize Your Heterojunction Device Performance

- Why is a steam generator and programmable furnace needed for emission aging? Replicate Real Hydrothermal Environments