Laboratory high-temperature resistance furnaces simulate industrial production by strictly replicating the thermal history of the steel through precise reheating control. specifically for 01YUT steel, these furnaces utilize defined heating rates, such as 3°C/s, to mimic the exact industrial heating sequences required before processing.

The core objective of using resistance furnaces is to reproduce the steel's thermodynamic state as it exists immediately prior to rolling, ensuring that laboratory microstructural observations accurately reflect real-world manufacturing conditions.

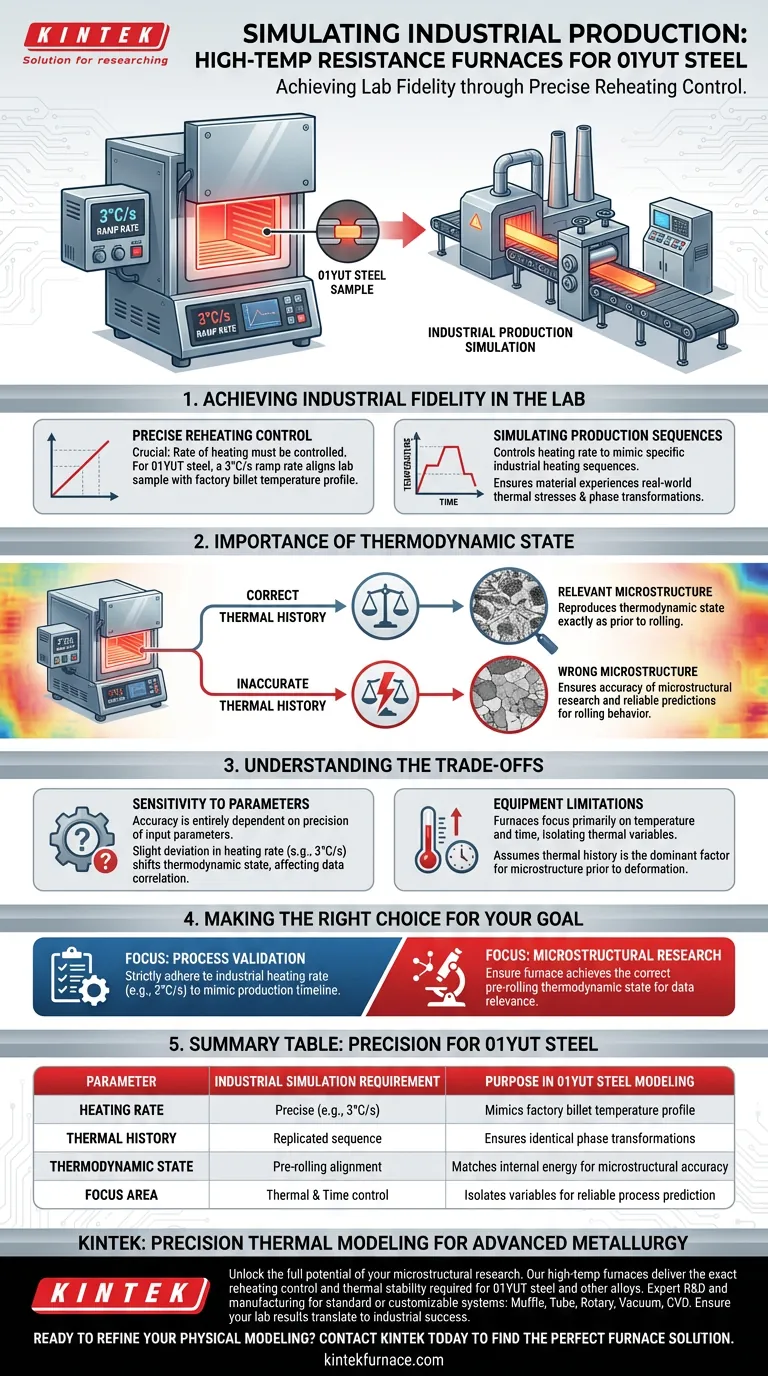

Achieving Industrial Fidelity in the Lab

Precise Reheating Control

To model industrial processes effectively, simple heating is insufficient; the rate of heating must be controlled.

High-temperature resistance furnaces allow researchers to program specific ramp rates. For 01YUT steel, a rate of 3°C/s is used to align the test sample's temperature profile with that of a factory billet.

Simulating Production Sequences

Industrial steel production involves complex thermal cycles, not just a static holding temperature.

By controlling the heating rate, the furnace simulates the specific industrial heating sequence. This ensures the material experiences the same thermal stresses and phase transformations in the lab as it would on the production line.

The Importance of the Thermodynamic State

Establishing Pre-Rolling Conditions

The validity of physical modeling hinges on the starting condition of the material.

These furnaces are designed to reproduce the thermodynamic state of the steel exactly as it would be prior to rolling. This aligns the internal energy and phase balance of the small-scale sample with the full-scale product.

Ensuring Microstructural Accuracy

If the thermal history is inaccurate, the resulting microstructure will be irrelevant to the actual product.

By securing the correct thermodynamic state, researchers ensure the accuracy of microstructural research. This allows for reliable predictions regarding how 01YUT steel will behave during the actual rolling process.

Understanding the Trade-offs

Sensitivity to Parameters

The accuracy of this simulation is entirely dependent on the precision of the input parameters.

If the heating rate (e.g., 3°C/s) deviates even slightly, the thermodynamic state may shift. This can lead to microstructural data that, while experimentally valid, does not correlate to the industrial output.

Equipment Limitations

While resistance furnaces excel at thermal control, they focus primarily on temperature and time.

They isolate the thermal variables effectively, but this requires the user to assume that thermal history is the dominant factor affecting the microstructure prior to mechanical deformation.

Making the Right Choice for Your Goal

To ensure your physical modeling yields actionable data for 01YUT steel, align your parameters with your specific objectives:

- If your primary focus is process validation: strictly adhere to the industrial heating rate (e.g., 3°C/s) to mimic the production timeline.

- If your primary focus is microstructural research: Ensure the furnace achieves the correct pre-rolling thermodynamic state to guarantee data relevance.

Success in physical modeling relies not just on reaching high temperatures, but on replicating the precise journey the material takes to get there.

Summary Table:

| Parameter | Industrial Simulation Requirement | Purpose in 01YUT Steel Modeling |

|---|---|---|

| Heating Rate | Precise (e.g., 3°C/s) | Mimics factory billet temperature profile |

| Thermal History | Replicated sequence | Ensures identical phase transformations |

| Thermodynamic State | Pre-rolling alignment | Matches internal energy for microstructural accuracy |

| Focus Area | Thermal & Time control | Isolates variables for reliable process prediction |

Precision Thermal Modeling for Advanced Metallurgy

Unlock the full potential of your microstructural research with KINTEK. Our laboratory high-temperature furnaces are engineered to provide the exact reheating control and thermal stability required to simulate complex industrial sequences for 01YUT steel and other specialized alloys.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temp furnaces or fully customizable systems for unique research needs, we deliver the precision you require to ensure your lab results translate perfectly to industrial success.

Ready to refine your physical modeling? Contact KINTEK today to find the perfect furnace solution.

Visual Guide

References

- O.G. Velychko, Yu.S. Proidak. Coordinated control of the composition of 01YUT steel and deformation processing modes to achieve specified mechanical properties. DOI: 10.15802/tpm.2.2024.06

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a two-stage sintering process used for porous LATP? Master Structural Integrity and Porosity

- What role does an industrial-grade walking beam heating furnace play in SSC bars? Ensure Optimal Metallurgical Bonding

- Why is the use of silver-containing active brazing alloys prohibited in TEGs? Prevent Semiconductor Degradation

- How does the holding time in a high-temperature furnace affect 0W Fe-C-B-Cr-W alloys? Optimize Phase Dissolution

- How does a high-precision temperature control system assist in evaluating the thermal management capabilities of phosphor materials? Pinpoint Performance for Solar Cells.

- What are the limitations of functional group grafting through high-temperature heating? Achieve Chemical Precision

- What are the three steps parts go through in a conveyor furnace? Master Sintering for Stronger Parts

- What causes the increase in specific gravity of Moso Bamboo? Master Cellular Densification in Heat Treatment