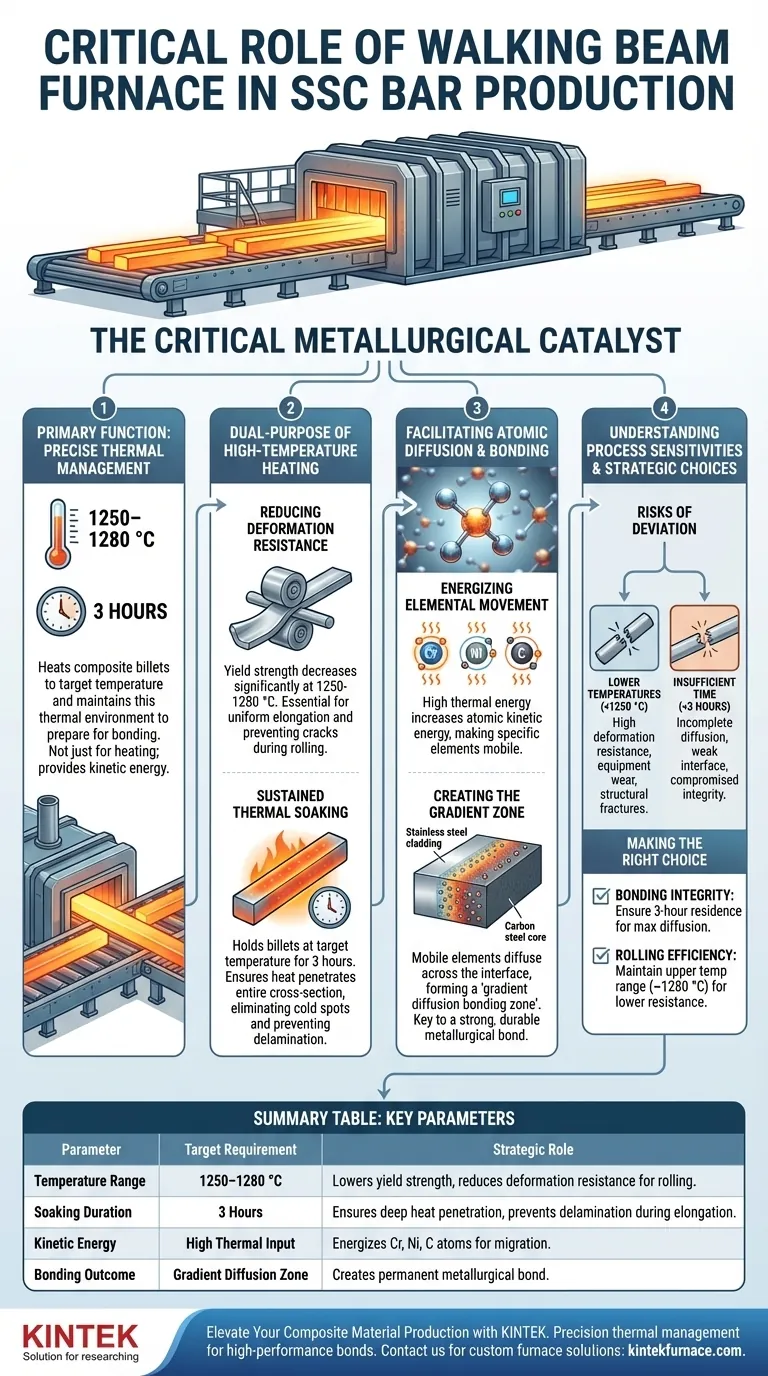

The industrial-grade walking beam heating furnace serves as the critical metallurgical catalyst in the production of stainless steel-clad carbon steel (SSC) bars. Its primary function is to heat composite billets to a precise temperature range of 1250–1280 °C and maintain this thermal environment for exactly three hours to prepare the materials for bonding.

This process does more than simply heat the metal; it provides the necessary kinetic energy for atomic migration, creating a gradient diffusion bonding zone that structurally unifies the stainless steel and carbon steel layers.

The Dual-Purpose of High-Temperature Heating

The furnace is not merely a staging area for the rolling mill; it is where the fundamental properties of the composite material are established.

Reducing Deformation Resistance

To successfully roll a composite billet into a bar, the material must be malleable.

The furnace heats the billet to between 1250 °C and 1280 °C.

At this temperature, the yield strength of the metal decreases significantly. This reduction in deformation resistance is essential for the subsequent rolling process, preventing cracks and ensuring uniform elongation.

Sustained Thermal Soaking

Reaching the target temperature is only the first step; maintaining it is equally vital.

The walking beam furnace holds the billets at the target temperature for a sustained duration of three hours.

This "soaking" period ensures that the heat penetrates through the entire cross-section of the billet, eliminating cold spots that could lead to delamination during rolling.

Facilitating Atomic Diffusion

The most distinct role of the furnace in SSC production is enabling the metallurgical bond between the two dissimilar metals.

Energizing Elemental Movement

Bonding stainless steel to carbon steel requires more than mechanical pressure; it requires chemical interaction at the interface.

The high thermal energy provided by the furnace increases the kinetic energy of the atoms within the metal.

This energy allows specific elements—namely chromium, nickel, and carbon—to become mobile.

Creating the Gradient Zone

Once mobilized, these elements diffuse across the interface between the stainless steel cladding and the carbon steel core.

This diffusion creates a "gradient diffusion bonding zone," where the composition transitions gradually rather than abruptly.

This zone is the key to a strong, durable bond that will not peel or separate under stress.

Understanding Process Sensitivities

While the furnace enables production, strict adherence to the process parameters is required to avoid failure.

The Risks of Lower Temperatures

If the temperature falls below the 1250 °C threshold, the deformation resistance remains too high.

This can lead to excessive wear on rolling equipment and potential structural fractures in the billet.

The Impact of Insufficient Time

If the three-hour soaking time is curtailed, the elemental diffusion will be incomplete.

Without sufficient time for chromium and nickel to migrate, the gradient zone will not form correctly.

This results in a weak interface, compromising the integrity of the final clad bar.

Making the Right Choice for Your Goal

The operation of the walking beam furnace must be tuned to your specific metallurgical requirements.

- If your primary focus is Bonding Integrity: Ensure the residence time is strictly maintained at 3 hours to maximize the diffusion of chromium and nickel across the interface.

- If your primary focus is Rolling Efficiency: Prioritize maintaining the upper temperature range (near 1280 °C) to minimize deformation resistance and reduce load on the rolling mill.

Precise thermal management is the difference between two separate metals and a single, unified high-performance composite.

Summary Table:

| Parameter | Targeted Requirement | Strategic Role in SSC Production |

|---|---|---|

| Temperature Range | 1250–1280 °C | Lowers yield strength and reduces deformation resistance for rolling. |

| Soaking Duration | 3 Hours | Ensures deep heat penetration and prevents delamination during elongation. |

| Kinetic Energy | High Thermal Input | Energizes Cr, Ni, and C atoms to initiate migration across the interface. |

| Bonding Outcome | Gradient Diffusion Zone | Creates a permanent metallurgical bond between stainless and carbon steel. |

Elevate Your Composite Material Production with KINTEK

Precision thermal management is the difference between a weak interface and a high-performance metallurgical bond. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab and industrial-grade high-temp furnaces tailored to your unique SSC production needs.

Whether you are refining atomic diffusion parameters or optimizing rolling efficiency, our technical team is ready to provide the specialized equipment you require.

Contact KINTEK Today to Discuss Your Custom Furnace Solution

Visual Guide

References

- G. X. Liang, T.‐H. Chen. Interfacial Bonding Properties Experimental Research of 316L Stainless Steel–Carbon Steel Clad Rebar in the Process of Intermediate and Finish Rolling. DOI: 10.3390/met15020108

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How are the effects of heat treatment furnace parameters on AlSi10Mg evaluated? Master Microstructural Analysis

- Why use a precision oven for moxa floss samples? Ensure Accurate Air-Drying Basis for Combustion Research

- Why is a high-precision blast drying oven used for Ni-Co/Ca catalyst preparation? Ensure Structural Integrity

- What is the purpose of high-temperature homogenization annealing? Optimizing Ti-5Al-2.5Sn-0.2C Alloy Ductility

- What is the function of zone melting purification equipment in the preparation of CsPbBr3 perovskite single crystals? Key for 6N.

- How does the pre-oxidation process affect high-temperature alloys? Enhancing Surface Integrity for Steam Cracking

- Why is stepped temperature control in a laboratory precision oven necessary? Mastering Porous TiCO Ceramic Curing

- What is the function of a high-pressure hydrothermal reactor in hydrochar synthesis? Unlock Biomass Transformation