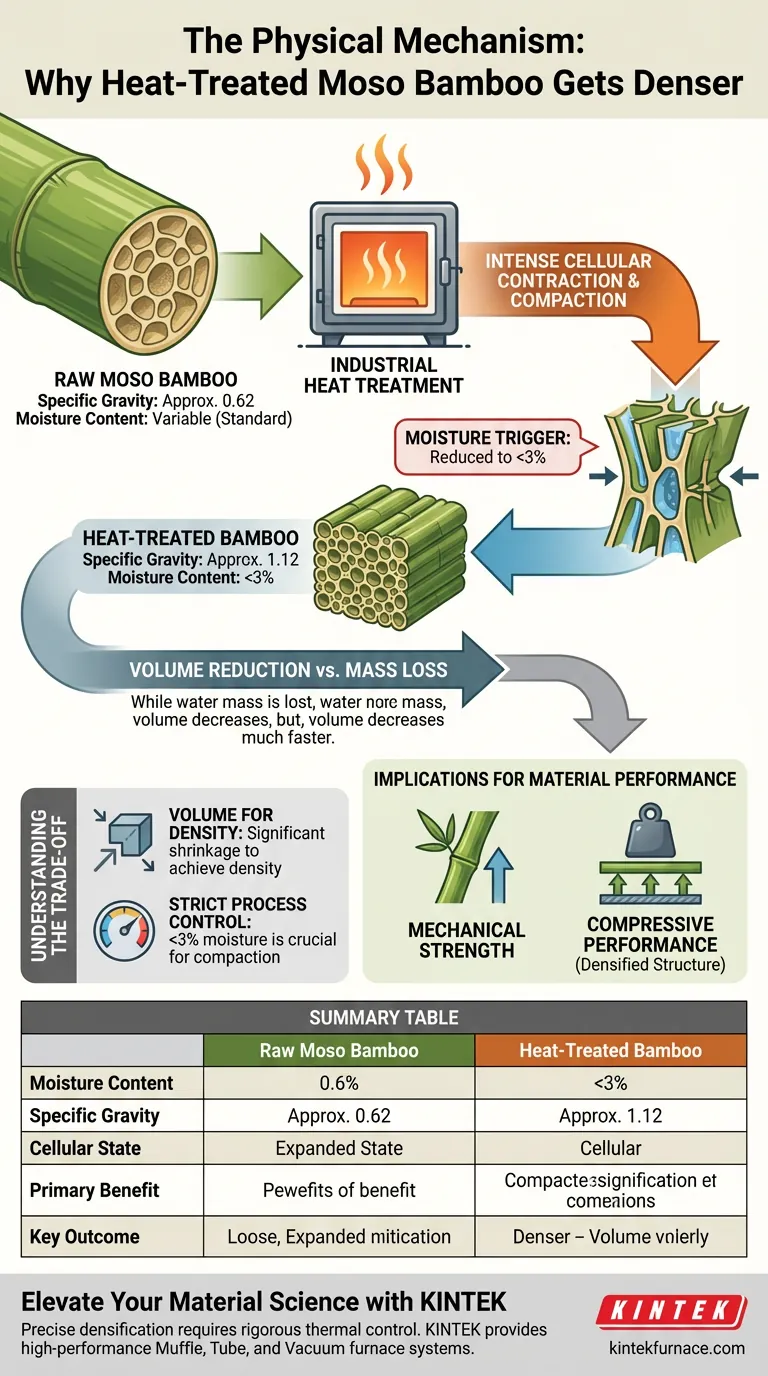

The physical mechanism driving the density increase in heat-treated Moso Bamboo is intense cellular contraction and compaction. When processed in industrial kilns, the bamboo is subjected to heat that reduces its moisture content to below 3%. This extreme drying triggers a structural collapse at the cellular level, causing the material's volume to shrink significantly while densifying the remaining matter.

Core Takeaway The transformation of Moso Bamboo is a trade-off between volume and density. By driving moisture down to near-zero levels (<3%), the process forces the cellular structure to contract and compact, nearly doubling the specific gravity from 0.62 to 1.12 and drastically enhancing its mechanical capabilities.

The Physics of Densification

The dramatic shift in specific gravity is not merely a result of removing water weight; it is a fundamental alteration of the bamboo's physical volume relative to its mass.

The Moisture Trigger

The process begins by reducing the moisture content of the bamboo to below 3%. This is significantly lower than standard equilibrium moisture levels, creating a state of extreme dryness that is necessary to initiate the physical changes.

Cellular Collapse

As the moisture evacuates the bamboo matrix, the cells undergo intense contraction. Without the internal pressure of moisture to maintain their original shape, the cellular walls are drawn closer together.

Volume Reduction vs. Mass

Specific gravity is a measure of density. While the bamboo loses mass (water), it loses volume at a much higher rate due to the compaction. This creates a much denser material within a smaller physical footprint, raising the specific gravity to approximately 1.12.

Implications for Material Performance

The physical compaction of the material directly translates into enhanced performance characteristics.

Mechanical Strength

The increase in specific gravity creates a direct correlation with mechanical strength. Because there is more physical material packed into a given cubic inch, the bamboo becomes significantly stronger than its raw counterpart.

Compressive Performance

The densified cellular structure offers superior resistance to crushing forces. The elimination of void spaces through compaction allows the treated bamboo to handle higher compressive loads.

Understanding the Trade-offs

While the heat treatment process yields a superior structural material, it involves a critical exchange of physical properties that must be understood.

Volume for Density

The primary trade-off in this process is volume shrinkage. To achieve the specific gravity of 1.12, the bamboo must physically shrink. You cannot achieve this level of density without accepting a reduction in the overall dimensions of the raw material.

Strict Process Control

Achieving this state requires precision. If the moisture content is not successfully brought below 3%, the necessary cellular contraction will not occur, and the bamboo will fail to reach the target density and associated strength.

Making the Right Choice for Your Goal

When evaluating heat-treated Moso Bamboo for industrial or structural applications, consider how the densification process aligns with your project needs.

- If your primary focus is Load-Bearing Capacity: Prioritize material that has confirmed a specific gravity near 1.12, as this indicates successful cellular compaction and maximum strength.

- If your primary focus is Material Efficiency: Recognize that the heat treatment process densifies the material through shrinkage, meaning the final product dimensions will be smaller than the raw input.

The value of heat-treated Moso Bamboo lies in its ability to convert a lightweight raw material into a compact, high-strength engineering resource through controlled cellular collapse.

Summary Table:

| Parameter | Raw Moso Bamboo | Heat-Treated Bamboo |

|---|---|---|

| Moisture Content | Variable (Standard) | < 3% |

| Specific Gravity | Approx. 0.62 | Approx. 1.12 |

| Cellular State | Expanded/Hydrated | Contracted/Compacted |

| Primary Benefit | Natural Flexibility | High Mechanical Strength |

| Key Outcome | High Volume/Low Density | Volume Shrinkage/High Density |

Elevate Your Material Science with KINTEK

Precise densification of Moso bamboo requires rigorous thermal control and exact moisture reduction. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, and Vacuum furnace systems tailored for advanced industrial heat treatment. Whether you are conducting material research or scaling production, our customizable lab solutions ensure your materials reach peak mechanical strength and density.

Ready to optimize your thermal processes? Contact our experts today to find the perfect furnace for your unique needs.

Visual Guide

References

- Yesun Kim, Se‐Yeong Park. Improvement of Moso Bamboo (Phyllostachys pubescens) Properties Using a Heat Treatment Process for Landscaping Materials and Evaluation of Its Durability against Biotic/Abiotic Factors. DOI: 10.3390/f15010101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does the secondary calcination process improve Na2WO4-loaded catalysts? Optimize Surface Performance Today

- How does an aluminum foil mask regulate temperature in the Floating-Zone process? Optimize Crystal Growth Precision

- What is the primary purpose of the 600°C annealing treatment? Optimize Silver-Coated Ceramic Performance

- What role does thermal processing with precise temperature control and tensile stress play in PVDF fiber stabilization?

- Why is a reaction vessel with pressure control necessary for Ru nanoparticle synthesis? Achieve Precision Morphology

- What role do high-temperature sintering furnaces play in ceramic SLA? Unlock 99% Density in 3D Printed Ceramics

- What is the primary purpose of continuously introducing high-purity argon gas? 4 Critical Roles in Solar Pyrolysis

- How does a precise temperature control system facilitate HDPE conversion? Optimize Your Catalytic Pyrolysis Efficiency