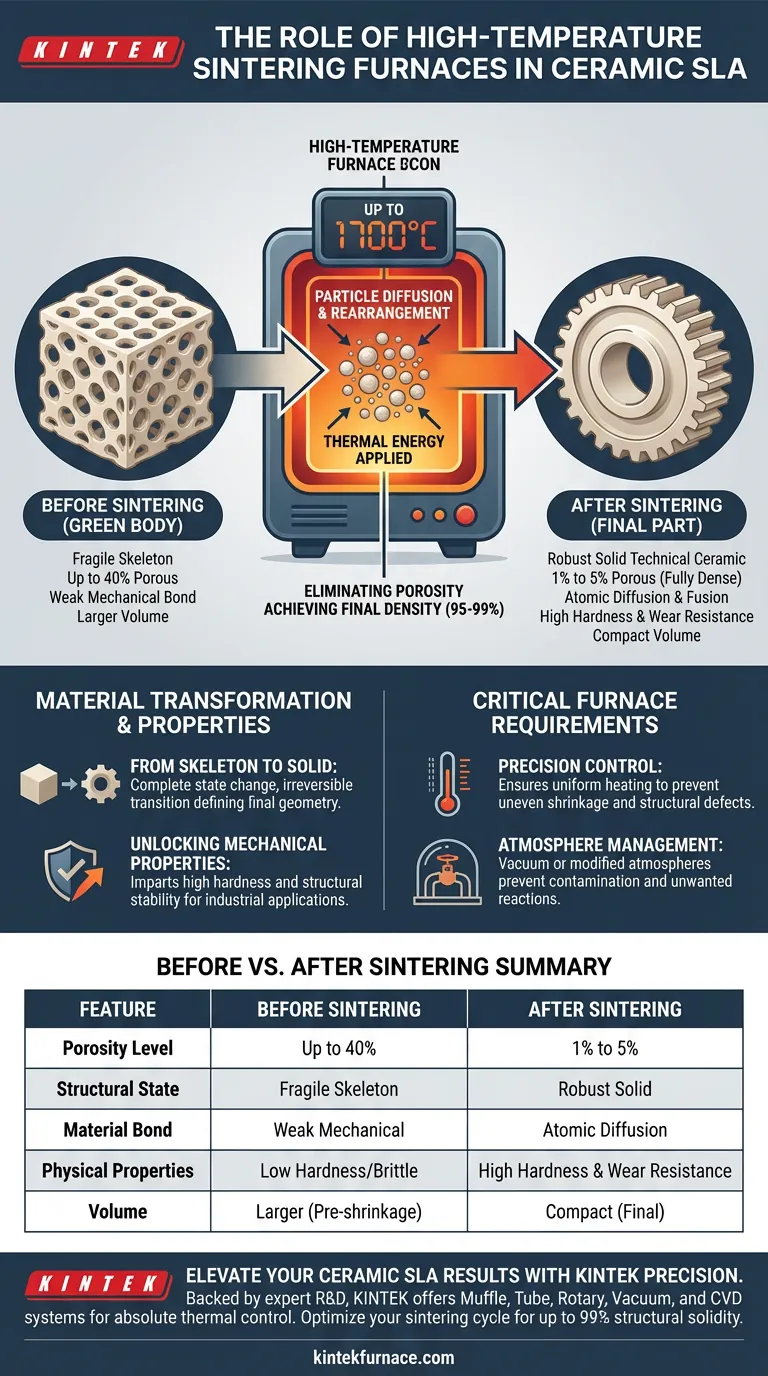

High-temperature sintering furnaces serve as the critical mechanism for densification in the final stage of ceramic Stereolithography (SLA). By applying extreme thermal energy, often reaching temperatures as high as 1700°C, these furnaces transform the porous ceramic skeleton remaining after the debinding process into a fully solid, high-performance component.

Core Takeaway: The sintering furnace drives a physical phase transformation through particle diffusion, converting a fragile part with up to 40% porosity into a dense technical ceramic with 95% to 99% structural solidity.

The Mechanics of Densification

Eliminating Porosity

The primary function of the furnace is to close the voids left within the material structure.

Before this stage, the ceramic part—often referred to as a "green body" or porous skeleton—contains up to 40% porosity. The furnace eliminates these gaps to achieve a solid entity.

Particle Diffusion and Rearrangement

Heat acts as the catalyst for atomic motion.

At specific temperatures below the melting point, ceramic particles begin to diffuse across boundaries. They rearrange and bond together, fusing into a cohesive mass without turning into liquid.

Achieving Final Density

The ultimate goal is structural integrity.

Through this thermal processing, the component reaches a final density between 95% and 99%. This high density is essential for the part to function as a true technical ceramic.

Material Transformation and Properties

From Skeleton to Solid

The furnace facilitates a complete state change.

What enters the furnace as a brittle, porous structure exits as a robust, unified object. This transition is irreversible and defines the final geometry of the part.

Unlocking Mechanical Properties

The sintering process dictates the material's performance characteristics.

By fusing the particles tightly, the furnace imparts high hardness and structural stability to the component. Without this high-temperature stage, the ceramic would lack the wear resistance required for industrial applications.

Critical Furnace Requirements and Trade-offs

Necessity of Precision Control

Sintering is not merely about reaching high temperatures; it is about controlling them.

Furnaces must possess precise temperature regulation to ensure even heating. Inconsistent thermal energy can lead to uneven shrinkage or structural defects.

Atmosphere Management

The environment inside the chamber is as important as the heat.

To prevent contamination or unwanted chemical reactions, these furnaces often operate under vacuum or modified atmospheres. This capability is vital for maintaining the purity of high-performance technical ceramics.

Making the Right Choice for Your Goal

To ensure your ceramic SLA process yields the best results, match your sintering parameters to your performance requirements.

- If your primary focus is mechanical strength: Ensure your furnace cycle is optimized to reach the upper limits of density (99%) through prolonged particle diffusion.

- If your primary focus is dimensional accuracy: Prioritize furnaces with superior temperature uniformity to control the shrinkage and rearrangement of particles precisely.

The success of a ceramic SLA print relies not just on the printer, but on the furnace's ability to finalize the material's physics.

Summary Table:

| Stage Feature | Before Sintering (Green Body) | After Sintering (Final Part) |

|---|---|---|

| Porosity Level | Up to 40% Porous | 1% to 5% (Fully Dense) |

| Structural State | Fragile Skeleton | Robust Solid Technical Ceramic |

| Material Bond | Weak Mechanical Bond | Atomic Diffusion & Fusion |

| Physical Properties | Low Hardness/Brittle | High Hardness & Wear Resistance |

| Volume | Larger (Pre-shrinkage) | Compact (Final Geometry) |

Elevate Your Ceramic SLA Results with KINTEK Precision

Transitioning from a fragile green body to a high-performance industrial component requires more than just heat—it requires absolute thermal control.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our high-temperature furnaces are specifically designed to manage the delicate shrinkage and atmosphere requirements of technical ceramics, ensuring your SLA parts achieve up to 99% structural solidity.

Whether you need custom temperature profiles for complex geometries or vacuum-capable chambers for material purity, our systems are customizable to your unique lab or production needs.

Ready to optimize your sintering cycle? Contact us today to find the perfect furnace solution.

Visual Guide

References

- Víctor Meana, Susana Martínez-Pellitero. Additive Manufacturing of Ceramic Reference Spheres by Stereolithography (SLA). DOI: 10.3390/app14177530

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What material is used in porcelain fused to metal restoration? A Guide to Alloys & Aesthetics

- What is the function of a high-pressure hydrothermal reactor in hydrochar synthesis? Unlock Biomass Transformation

- What are the core technical advantages of an industrial microwave sintering system? Gain Speed and Material Integrity

- How does temperature control precision affect SC-NMNO crystal morphology? Master Thermal Fields for High-Quality Grains

- How does a continuous furnace differ from a batch furnace? Optimize Your Heat Treatment Process

- How does the thermal field length impact YAG fiber dip coatings? Achieve Uniform, Bead-Free Films

- What is the role of a 5% N2 + 95% H2 mixture in plasma nitriding? Enhance Fatigue Strength and Eliminate White Layers

- What role does a high-temperature annealing furnace play in the preparation of AAO substrates? Enhance Pore Regularity