The fundamental technical advantage of an industrial microwave sintering system is its ability to generate heat from within the material itself via "volume heating," rather than relying on external thermal conduction. By utilizing high-frequency microwaves to couple directly with ceramic dipoles, this technology achieves uniform internal heating, enabling rapid temperature escalation and significantly reduced processing times compared to traditional resistance furnaces.

Core Takeaway: Traditional furnaces heat from the outside in, creating thermal gradients and requiring slow ramp rates. Industrial microwave sintering flips this paradigm by creating a volume heating effect, allowing for heating rates up to 100°C per minute while preserving an ultrafine crystalline structure.

The Mechanism: Volume Heating vs. Thermal Conduction

To understand the efficiency of microwave sintering, one must first understand the limitations of the traditional approach.

The Limitation of Traditional Heating

Traditional resistance furnaces operate on a surface-to-core principle. Heat generates at the elements, transfers to the ceramic surface, and then must slowly conduct inward to the center of the part.

The Power of Volume Heating

Microwave systems utilize high-frequency microwaves to couple directly with the ceramic dipoles inside the zirconia.

This interaction generates heat uniformly throughout the entire volume of the material simultaneously. This mechanism eliminates the reliance on thermal conduction from the surface, which is the primary bottleneck in traditional sintering.

Operational Efficiency and Speed

The shift to volume heating creates immediate, measurable improvements in process metrics.

Achieving Rapid Heating Rates

Because heat is generated internally, the thermal lag associated with conduction is eliminated. This allows for aggressive heating rates of up to 100°C per minute.

Lower Energy Consumption

The sintering cycle is significantly shortened due to these rapid heating rates. Consequently, the total energy required to process a batch of zirconia is notably reduced compared to the long dwell times of resistance furnaces.

Impact on Material Structure

Beyond speed, the thermodynamics of microwave sintering have a profound effect on the physical quality of the zirconia.

Preserving Ultrafine Grain Structure

In traditional sintering, prolonged exposure to high heat creates a window for grains to enlarge, which can weaken the mechanical properties of the ceramic.

The Thermodynamic Advantage

The rapid thermodynamics of the microwave system effectively inhibit grain growth. By minimizing the time the material spends at critical grain-coarsening temperatures, the system produces zirconia ceramics with an ultrafine crystalline structure.

Understanding the Trade-offs

While microwave sintering offers superior speed and structure, it is distinct from other rapid techniques and requires specific material conditions.

Material Dependency

The entire process relies on the material's ability to physically interact with the energy source. Success is dictated by the coupling of high-frequency microwaves with ceramic dipoles.

If a material does not possess the correct dielectric properties to facilitate this coupling, the volume heating effect cannot occur.

Making the Right Choice for Your Goal

When deciding between a traditional resistance furnace and an industrial microwave sintering system, consider your specific production drivers.

- If your primary focus is Production Throughput: Leverage the volume heating effect to achieve heating rates of 100°C/minute, drastically reducing your total cycle time.

- If your primary focus is Material Performance: Utilize the rapid thermodynamic profile to inhibit grain growth, ensuring your final product retains an ultrafine crystalline structure.

By moving from surface conduction to internal volume heating, you achieve a simultaneous increase in processing speed and material quality.

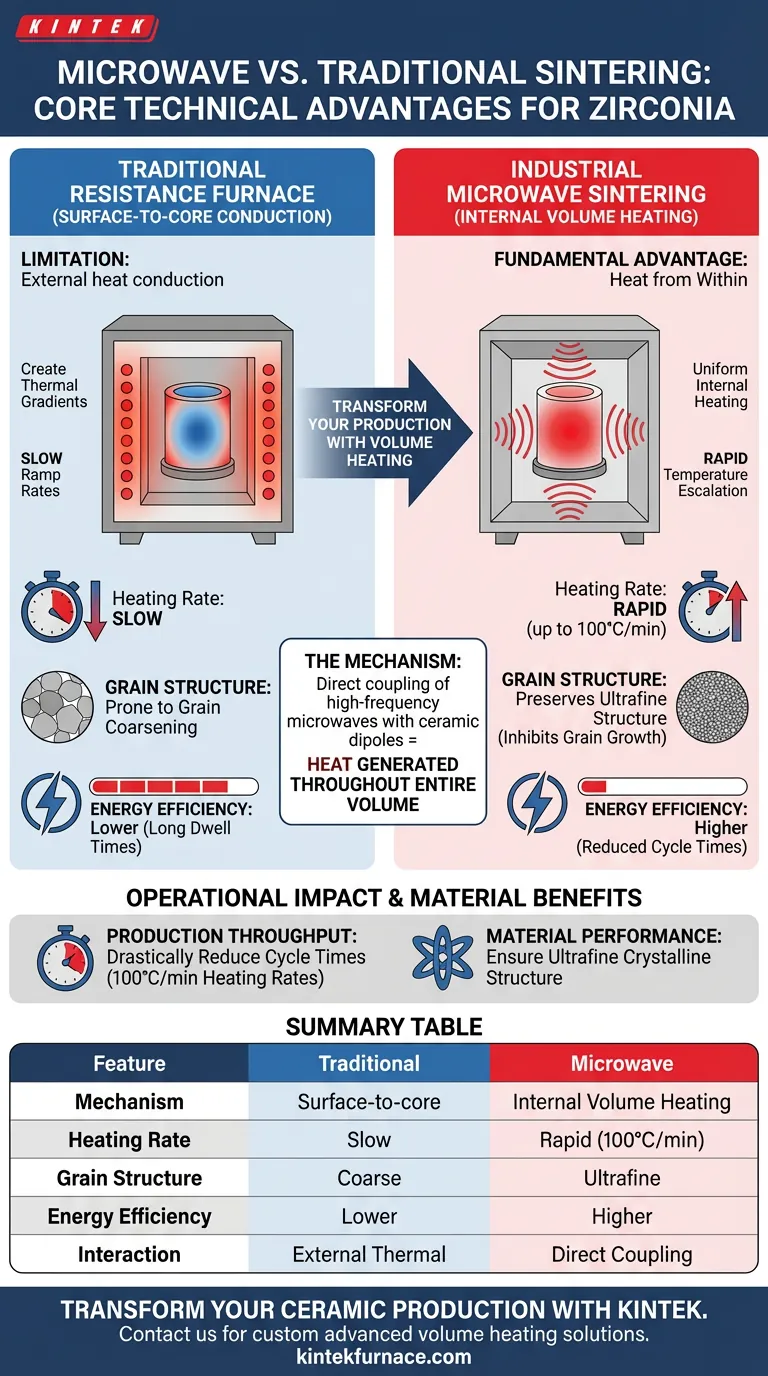

Summary Table:

| Feature | Traditional Resistance Furnace | Industrial Microwave Sintering |

|---|---|---|

| Heating Mechanism | Surface-to-core conduction | Internal volume heating |

| Heating Rate | Slow (limited by thermal lag) | Rapid (up to 100°C/minute) |

| Grain Structure | Prone to grain coarsening | Preserves ultrafine structure |

| Energy Efficiency | Lower (long dwell times) | Higher (reduced cycle times) |

| Material Interaction | External thermal transfer | Direct coupling with dipoles |

Transform Your Ceramic Production with KINTEK

Are you looking to drastically reduce your sintering cycles while achieving superior material properties? KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing.

Whether you require specialized Microwave Sintering, Vacuum, CVD, or Muffle systems, our high-temp lab furnaces are fully customizable to meet your unique processing needs. Don't let traditional heating bottlenecks limit your throughput—partner with KINTEK to integrate advanced volume heating into your workflow.

Ready to optimize your lab's performance? Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Dilsuz A. Abdaljabar, Ahmed Abdulrasool Ahmed Alkhafaji. Using Taguchi Technique to Study the Effect of Adding Copper Nano on Shape Recovery for Smart Alloy (CU-AL-NI). DOI: 10.31026/j.eng.2025.05.03

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- Why is a precision temperature control system essential for wood carbonization? Achieve Perfect Shape Fidelity

- What is the function of planetary ball mills or industrial mixing granulators prior to RHF? Optimize FMDS Reactivity

- How do laboratory high-temperature resistance furnaces simulate industrial production processes for 01YUT steel?

- How does the control of gas flow and reaction time affect NiMo catalyst carbon layers? Master Nanostructure Engineering

- How does controlled thermal treatment affect delta-MnO2? Optimize Porosity & Surface Area for Better Battery Performance

- Why is a specific glass slide used to cover Zinc powder? Mastering ZnO Nanostructure Precision

- What type of reaction environment is required for the synthesis of Ge-Se-Tl-Sb chalcogenide glasses? | KINTEK

- What role do RTP or continuous sintering furnaces play in solar cell electrode formation? Optimize Your Firing Process