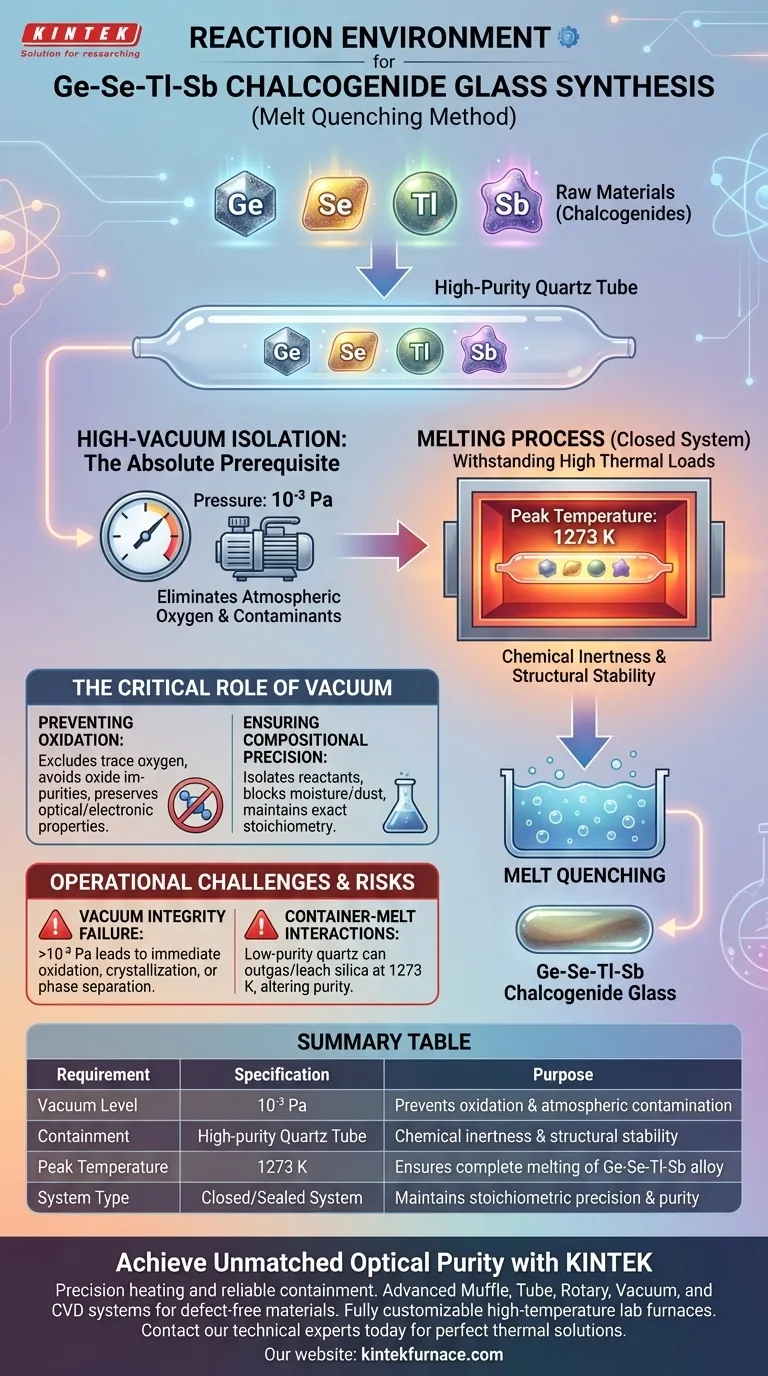

High-vacuum isolation is the absolute prerequisite for synthesizing Ge-Se-Tl-Sb chalcogenide glasses via melt quenching. Specifically, the reaction requires sealing raw materials within high-purity quartz tubes that have been evacuated to a pressure of 10⁻³ Pa. This sealed, oxygen-free environment is maintained throughout the melting process, which reaches temperatures as high as 1273 K.

The synthesis of high-purity chalcogenide glass relies on a closed system under high vacuum (10⁻³ Pa) to completely eliminate atmospheric oxygen and contaminants, preventing oxidation and ensuring precise alloy composition during high-temperature melting.

The Critical Role of the Vacuum Environment

Preventing Oxidation

The primary function of the 10⁻³ Pa vacuum is the exclusion of oxygen.

Chalcogenide elements (Ge, Se, Tl, Sb) are highly susceptible to oxidation at elevated temperatures. Even trace amounts of atmospheric oxygen can react with the melt, creating oxide impurities that degrade the optical and electronic properties of the final glass.

Ensuring Compositional Precision

Beyond oxidation, the sealed environment protects the stoichiometry of the alloy.

By isolating the reactants in a closed quartz system, you prevent the introduction of atmospheric moisture and dust. This ensures that the final glass composition strictly matches the intended Ge-Se-Tl-Sb ratio without external contamination.

Withstanding High Thermal Loads

The reaction environment must maintain its integrity under extreme heat.

The synthesis process involves heating the materials to 1273 K. High-purity quartz is selected as the containment material because it remains chemically inert and structurally stable at these temperatures, unlike standard glass or lesser ceramics.

Operational Challenges and Risks

Vacuum Integrity Failure

The success of the synthesis is binary; if the vacuum is compromised, the material is ruined.

If the pressure rises above 10⁻³ Pa due to a micro-leak or improper sealing, oxidation will occur immediately. This often results in crystallization or phase separation rather than the formation of a homogeneous glass.

Container-Melt Interactions

While quartz is robust, it is not invincible.

At 1273 K, the reactive melt is in direct contact with the tube walls. It is vital to use high-purity quartz to prevent the tube itself from outgassing or leaching silica into the chalcogenide melt, which would alter the refractive index and purity of the glass.

Ensuring Synthesis Success

To achieve optimal results with Ge-Se-Tl-Sb glasses, you must prioritize the quality of your containment and evacuation systems.

- If your primary focus is optical purity: Ensure your vacuum system can reliably sustain 10⁻³ Pa or lower to eliminate absorption bands caused by oxides.

- If your primary focus is mechanical stability: Verify that the quartz ampoules are rated for temperatures exceeding 1273 K to prevent rupture during the melt quenching phase.

Strict adherence to high-vacuum protocols is the only way to guarantee a homogeneous, defect-free chalcogenide glass.

Summary Table:

| Requirement | Specification | Purpose |

|---|---|---|

| Vacuum Level | 10⁻³ Pa | Prevents oxidation and atmospheric contamination |

| Containment | High-purity Quartz Tube | Chemical inertness and structural stability |

| Peak Temperature | 1273 K | Ensures complete melting of Ge-Se-Tl-Sb alloy |

| System Type | Closed/Sealed System | Maintains stoichiometric precision and purity |

Achieve Unmatched Optical Purity with KINTEK

High-vacuum synthesis of chalcogenide glasses demands precision heating and reliable containment. KINTEK provides the advanced technology needed to ensure your materials remain defect-free. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature lab furnaces—all fully customizable to meet your unique synthesis requirements.

Ready to elevate your material research? Contact our technical experts today to find the perfect thermal solution for your laboratory.

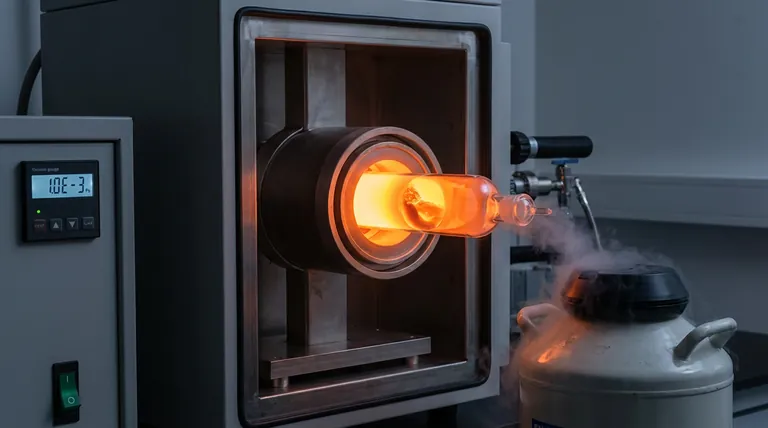

Visual Guide

References

- A. M. Ismail, E.G. El-Metwally. Insight on the optoelectronic properties of novel quaternary Ge–Se–Tl–Sb non-crystalline glassy alloy films for optical fiber sensing devices. DOI: 10.1140/epjp/s13360-024-05012-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What happens during the recovery stage of the annealing process? Unlock Stress Relief and Material Restoration

- What functions does glucose perform in lithium-ion sieve synthesis? Enhance Carbothermal Reduction for LiMnO2 Purity

- How does a refining furnace achieve the separation of impurities? Mastering High-Purity White Phosphorus Production

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- What are the primary purposes of using high-purity argon flow during the pyrolysis of CMS membranes? Achieve High-Purity Results

- What are the advantages of using ultrasonic spray pyrolysis for metal powder? Achieve High Purity & Sphericity

- What are the functions of hot isostatic pressing (HIP) equipment? Achieve Peak Density in Powder Metallurgy

- Why are varied heating rates applied during oil shale pyrolysis? Optimize Kinetics and Technical Validation