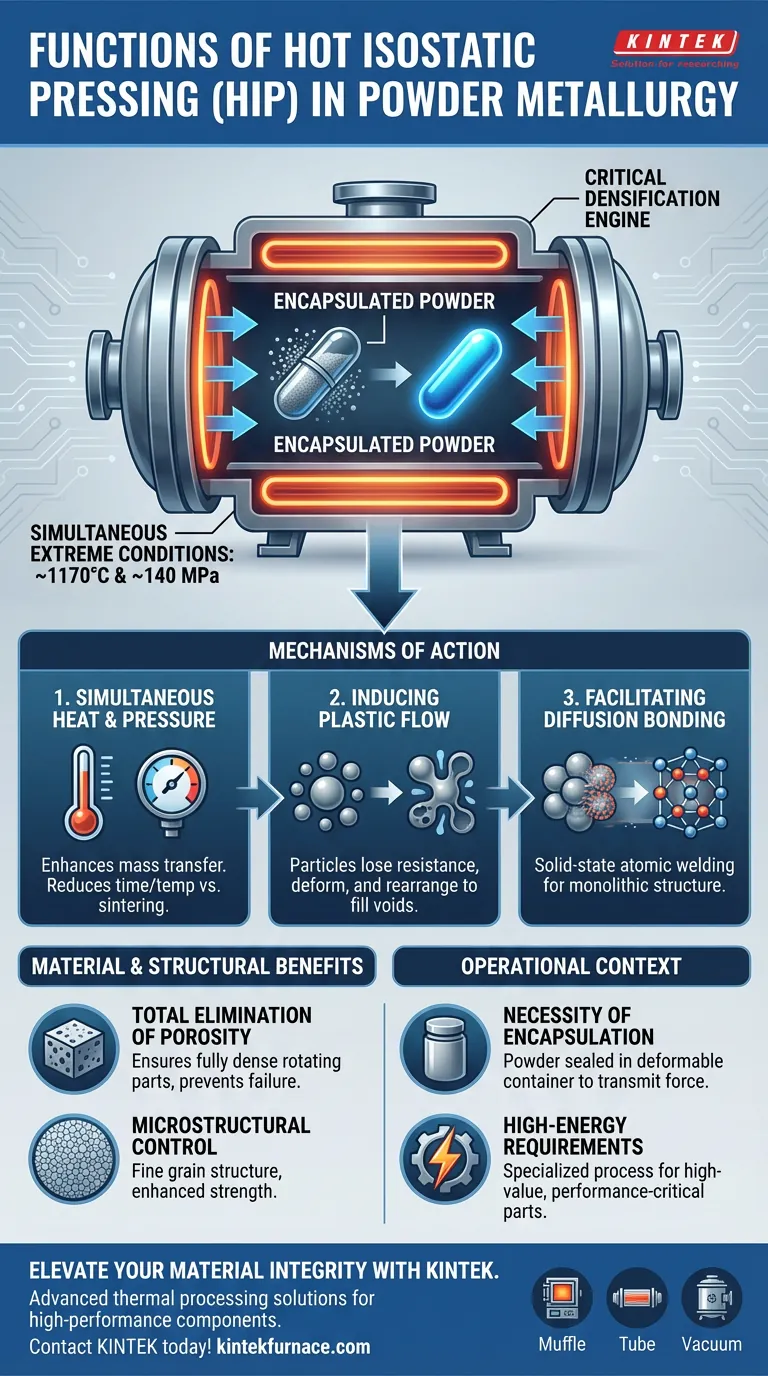

Hot Isostatic Pressing (HIP) equipment functions as the critical densification engine in the manufacturing of high-performance powder metallurgy components. By simultaneously subjecting alloy powders to extreme temperatures of approximately 1170°C and high pressures around 140 MPa, the equipment drives the material to achieve full density and superior structural integrity.

The core value of HIP lies in its ability to eliminate internal flaws through physics rather than mechanical force alone. By triggering plastic flow and diffusion bonding, HIP transforms loose powder into a solid, porosity-free material that meets the rigorous demands of high-strength rotating parts.

Mechanisms of Action

Applying Simultaneous Heat and Pressure

The primary function of HIP equipment is to create an environment where heat and pressure act concurrently.

Unlike processes that separate these steps, HIP applies approximately 140 MPa of pressure alongside temperatures near 1170°C.

This dual application enhances mass transfer, significantly reducing the time and temperature required compared to conventional sintering.

Inducing Plastic Flow

Under these extreme conditions, the powder particles lose their resistance to deformation.

The equipment forces the material into a thermoplastic state, causing plastic flow.

This allows particles to rearrange and fill even the smallest voids within the capsule, achieving a density that approaches theoretical limits.

Facilitating Diffusion Bonding

Beyond simple compaction, HIP equipment drives atomic-level bonding.

The process facilitates diffusion bonding between powder particles.

This solid-state welding eliminates the boundaries between particles, resulting in a cohesive, monolithic structure rather than a cluster of pressed grains.

Material and Structural Benefits

Total Elimination of Porosity

The most critical outcome of the HIP process is the removal of internal voids.

By crushing pores through isostatic pressure, the equipment ensures the final component is fully dense.

This is essential for rotating parts, where even microscopic porosity can lead to catastrophic failure under load.

Microstructural Control

HIP equipment enables superior control over the metal's internal grain structure.

Because the process is efficient, it prevents excessive grain growth that often occurs during prolonged heating.

This results in a fine grain structure, which directly correlates to enhanced mechanical properties and strength.

Understanding the Operational Context

The Necessity of Encapsulation

It is important to recognize that HIP is not applied directly to loose powder in an open chamber.

The primary reference notes that this process occurs within a capsule.

The powder must be sealed in a container that deforms under pressure to transmit the force to the powder effectively.

High-Energy Requirements

While HIP reduces the mechanical stress needed compared to cold pressing (by leveraging the thermoplastic state), it is still an energy-intensive process.

The equipment must maintain high-pressure containment while generating temperatures over 1000°C.

This makes it a specialized process reserved for high-value components where performance is non-negotiable.

Making the Right Choice for Your Goal

To maximize the value of Hot Isostatic Pressing in your fabrication process, consider your specific performance targets:

- If your primary focus is mechanical reliability: Prioritize HIP for its ability to eliminate porosity, ensuring the fatigue resistance required for rotating parts.

- If your primary focus is material properties: Leverage the process to achieve fine grain structures and near-theoretical density through diffusion bonding.

By utilizing HIP, you are not just shaping metal; you are engineering its internal structure to withstand the most demanding operational environments.

Summary Table:

| Function | Mechanism | Impact on Component |

|---|---|---|

| Densification | Simultaneous Heat & Pressure | Eliminates internal voids and porosity |

| Material Flow | Inducing Plastic Flow | Forces particles into a solid, theoretical density state |

| Structural Unity | Diffusion Bonding | Atomic-level bonding for a monolithic structure |

| Grain Control | Thermal Stability | Prevents excessive grain growth for high strength |

Elevate Your Material Integrity with KINTEK

Unlock the full potential of your high-performance components with KINTEK’s advanced thermal processing solutions. Backed by expert R&D and world-class manufacturing, we provide high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique powder metallurgy and sintering requirements. Whether you are aiming for near-theoretical density or superior fatigue resistance, our equipment delivers the reliability your lab demands.

Ready to optimize your fabrication process? Contact KINTEK today for a consultation!

Visual Guide

References

- Yufeng Liu, Guoqing Zhang. Effects of Oxygen Content on Microstructure and Creep Property of Powder Metallurgy Superalloy. DOI: 10.3390/cryst14040358

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of using an industrial-grade oven for segmented drying? Optimize Electrode Integrity & Adhesion

- What role does a high-pressure reactor play in the production of hydrochar? Optimize Biomass Carbonization

- What preparatory questions should be addressed before converting to electrically heated processes? Ensure a Smooth Transition to Electric Heating

- What role does a high-temperature annealing furnace play in the preparation of AAO substrates? Enhance Pore Regularity

- Why is it necessary to use a vacuum drying oven for porous graphene cathodes? Ensure Peak Battery Performance

- What are the main types of laboratory furnaces based on size? Find the Perfect Fit for Your Lab's Scale

- What is quenching, and why is it important? Achieve Superior Material Hardness and Strength

- What is the specific function of hydrogen and helium in quartz glass melting? Optimize Your High-Temp Processes