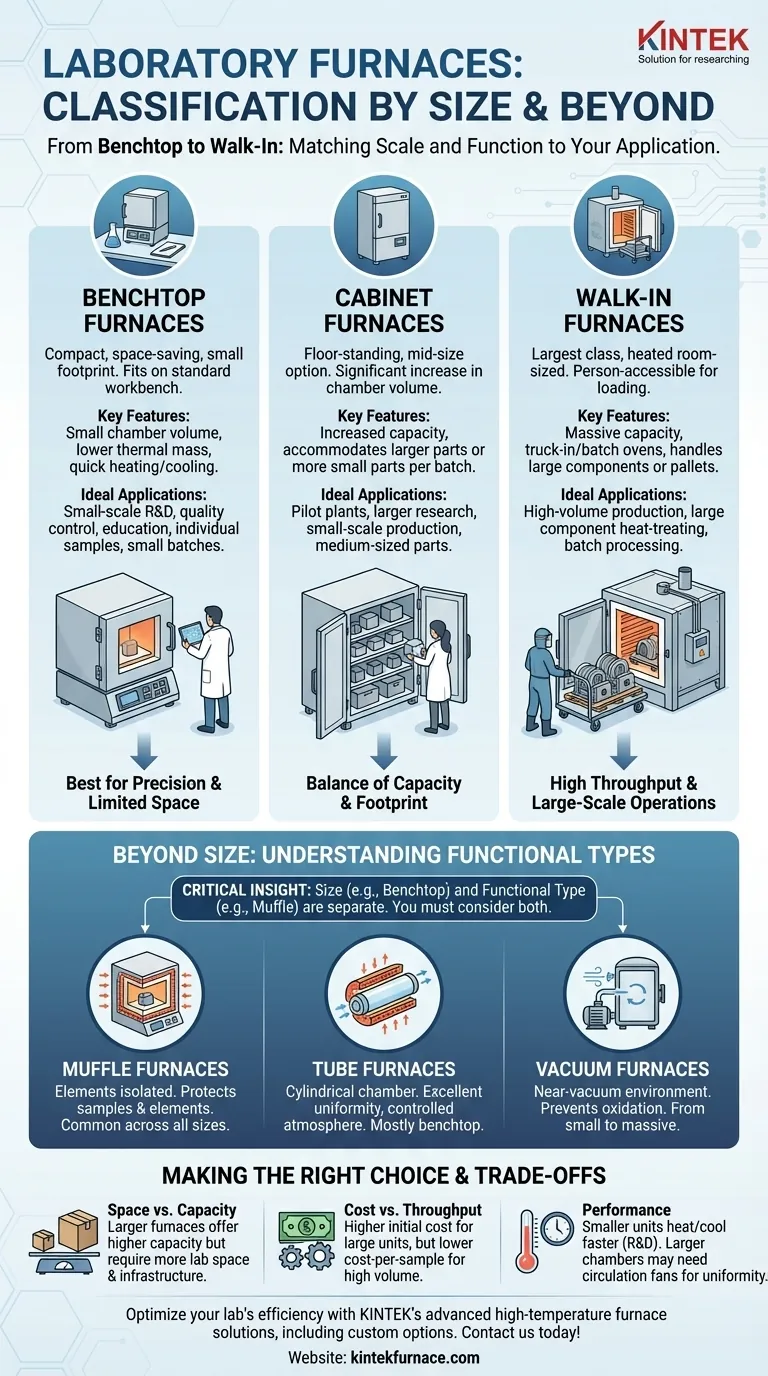

When selecting a laboratory furnace, its physical size is the most immediate classification, determining its footprint and sample capacity. The three main types based on size are benchtop, cabinet, and walk-in furnaces. Each is designed to fit a different scale of operation, from small-scale research on a lab bench to large-scale industrial batch processing.

The most critical insight is that furnace size (benchtop, cabinet) and functional type (muffle, tube) are two separate classifications. The right choice is never about size alone, but about matching both the physical footprint and the heating technology to your specific application's requirements.

The Three Core Size Categories

The physical form factor of a furnace dictates where it can be installed and the volume or quantity of samples it can process at one time. This is the first and most fundamental decision point.

Benchtop Furnaces

These are the smallest and most common furnaces found in research, quality control, and educational labs. As the name implies, they are compact enough to sit on a standard laboratory workbench.

Their primary advantage is their small footprint, making them ideal for labs with limited space. They are best suited for processing small individual samples or small batches.

Cabinet Furnaces

Cabinet furnaces are the mid-size option, designed as floor-standing units. They offer a significant increase in internal chamber volume compared to benchtop models.

These are the workhorses for pilot plants, larger research projects, and small-scale production. They can accommodate larger parts or a greater number of smaller parts in a single batch, increasing throughput.

Walk-In Furnaces

Also known as truck-in or batch ovens, these are the largest class of laboratory and industrial furnaces. They are essentially heated rooms large enough for a person to enter.

Materials are typically loaded onto carts or racks and wheeled into the chamber. These are used for high-volume production, heat-treating very large components, or processing entire pallets of material at once.

Beyond Size: Understanding Functional Types

Classifying a furnace by size only tells half the story. The internal design, which dictates how the heat is delivered, is equally important. A furnace is often described by both its size and its functional type.

The Critical Distinction

A "benchtop muffle furnace" is a common example. Benchtop describes its size, while muffle describes its heating method. You must consider both factors to find the right instrument.

Muffle Furnaces

This is the most common functional type. In a muffle furnace, the heating elements are physically isolated from the internal chamber, often separated by a ceramic "muffle."

This design protects samples from direct radiation and contamination from the heating elements. It also protects the elements from any corrosive fumes the samples might emit, extending furnace life. Muffle furnaces are available in all three size categories.

Tube Furnaces

Tube furnaces use a cylindrical heating chamber, typically made of ceramic or quartz. They are designed to heat samples within a narrow tube.

Their primary advantage is excellent temperature uniformity along the central heated zone. They are ideal for processes requiring a controlled atmosphere, as gases can be flowed through the tube over the sample. Most tube furnaces are benchtop models.

Vacuum Furnaces

This is a specialized functional type designed to heat materials in a near-vacuum environment. Removing the atmosphere prevents oxidation and other unwanted chemical reactions at high temperatures.

Vacuum furnaces can range from small benchtop units for R&D to massive industrial systems for aerospace or medical device manufacturing.

Understanding the Trade-offs

Choosing a furnace size involves balancing capacity against cost, space, and performance characteristics. There is no single "best" size.

Space vs. Capacity

The most obvious trade-off is lab space. A larger furnace provides higher processing capacity but demands a significantly larger operational footprint and often requires dedicated facility infrastructure for power and ventilation.

Cost vs. Throughput

Larger furnaces have a higher initial purchase price and higher ongoing energy costs. However, for high-volume applications, their ability to process more material at once can lead to a lower cost-per-sample, justifying the investment.

Performance Considerations

Smaller furnaces generally have lower thermal mass, allowing them to heat up and cool down more quickly. This can be a major advantage in R&D settings where rapid iteration is needed. Larger chambers may struggle with temperature uniformity unless equipped with circulation fans and multi-zone controls.

Making the Right Choice for Your Goal

Select your furnace by matching its size and functional type to your primary operational objective.

- If your primary focus is small-scale R&D or quality control: A benchtop furnace, likely a muffle or tube type, offers the best balance of precision, control, and efficient use of lab space.

- If your primary focus is batch processing or medium-sized parts: A cabinet furnace provides the necessary capacity for pilot-scale work or light production without the massive infrastructure needs of an industrial-scale unit.

- If your primary focus is high-volume production or very large components: A walk-in furnace is the necessary choice for industrial-scale operations where maximizing throughput and accommodating large items is the main driver.

By understanding how size and functional type intersect, you can select a furnace that is a precise and effective tool for your specific scientific or industrial goal.

Summary Table:

| Size Type | Key Features | Ideal Applications |

|---|---|---|

| Benchtop | Compact, space-saving, small footprint | Small-scale R&D, quality control, education |

| Cabinet | Floor-standing, increased chamber volume | Pilot plants, larger research, small-scale production |

| Walk-in | Large capacity, person-accessible | High-volume production, large components, batch processing |

Ready to optimize your lab's efficiency with the right furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your processes with tailored furnace solutions!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors