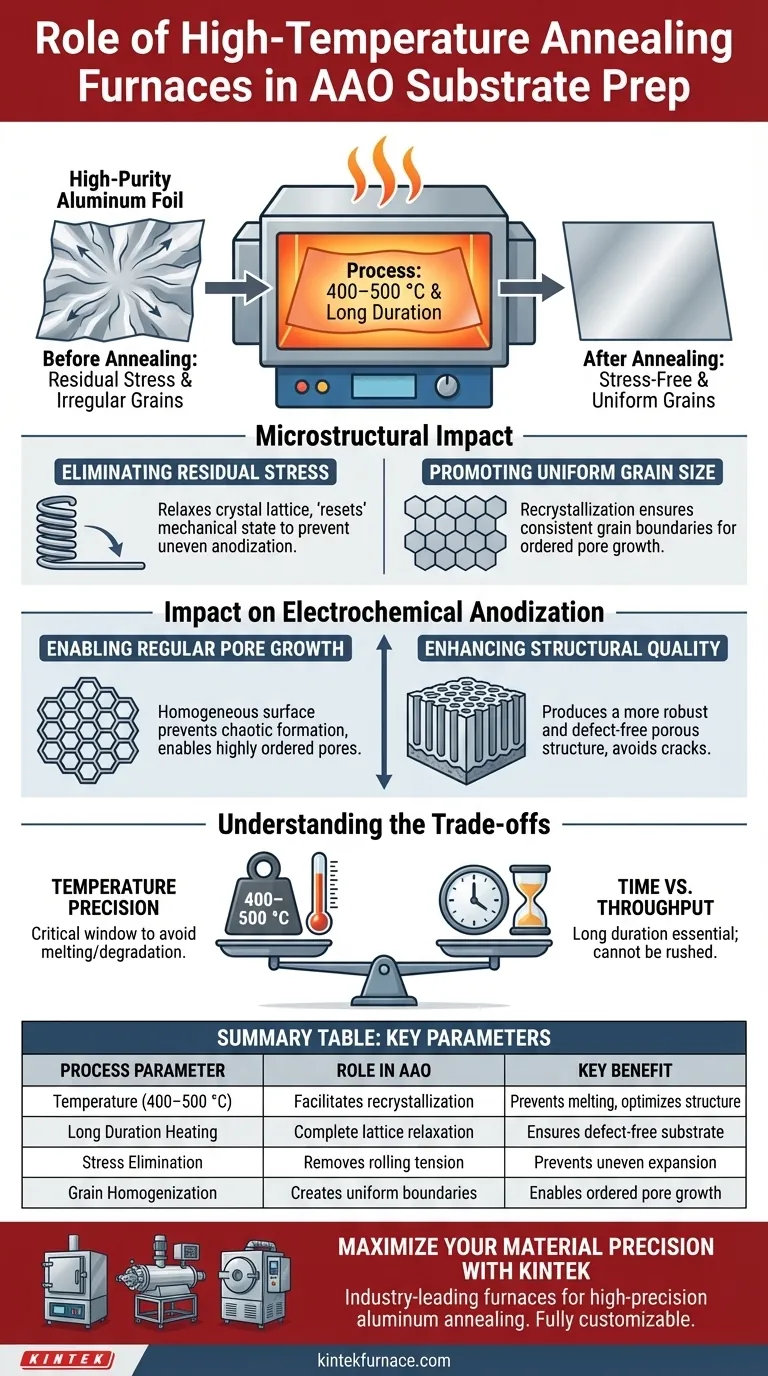

A high-temperature annealing furnace serves as a critical pre-treatment tool for stabilizing high-purity aluminum foil before it undergoes electrochemical anodization. By maintaining specific temperatures between 400 and 500 °C for extended durations, the furnace fundamentally alters the microstructure of the aluminum. This step eliminates residual mechanical stresses and homogenizes the metal's grain structure, creating the necessary conditions for high-quality Anodic Aluminum Oxide (AAO) fabrication.

The primary function of the annealing furnace is to standardize the aluminum substrate by removing internal stress and promoting uniform grain size. This thermal conditioning is the prerequisite for achieving the highly regular, ordered pore growth that defines high-quality AAO.

The Microstructural Impact of Annealing

Eliminating Residual Stress

During the manufacturing and rolling of high-purity aluminum foil, significant residual mechanical stresses accumulate within the material.

If left untreated, these internal stresses cause uneven expansion and reaction rates during the subsequent anodization process.

The annealing furnace applies controlled heat to relax the crystal lattice, effectively "resetting" the material's mechanical state.

Promoting Uniform Grain Size

Beyond stress relief, the furnace plays a pivotal role in recrystallization.

Holding the aluminum at temperatures between 400 and 500 °C encourages the grains within the metal to reorganize and grow into a uniform size.

Uniform grain size is paramount because the boundaries between grains can disrupt the electrical field during anodization, leading to defects in the final oxide layer.

Impact on Electrochemical Anodization

Enabling Regular Pore Growth

The ultimate goal of producing AAO is to create a highly ordered, hexagonal pore arrangement.

The "regularity" of these pores is strictly dependent on the homogeneity of the starting aluminum surface.

By pre-treating the foil in the furnace, you ensure the electrochemical reaction proceeds at a consistent rate across the entire surface, preventing chaotic or branched pore formation.

Enhancing Structural Quality

A substrate that has been properly annealed produces a more robust and defect-free porous structure.

Without the furnace treatment, the final AAO template is likely to exhibit cracks, uneven pore diameters, or structural distortions caused by the underlying stress in the aluminum.

Understanding the Trade-offs

Temperature Precision is Critical

While high temperatures are necessary for recrystallization, there is a strict upper limit.

You must operate within the 400–500 °C window defined by the primary guidelines for aluminum.

Exceeding this range brings you dangerously close to the melting point of aluminum (~660 °C) or may cause excessive grain growth that actually degrades surface quality, unlike the much higher temperatures (e.g., 700 °C) used for other materials like gallium oxide films.

Time vs. Throughput

This process is defined by long-duration heat treatment.

It is a bottleneck in terms of manufacturing speed; you cannot rush the relaxation of the crystal lattice.

Attempting to shorten the annealing time to increase throughput will result in incomplete stress relief, leading to inferior pore ordering in the final product.

Making the Right Choice for Your Goal

To maximize the effectiveness of your AAO preparation, align your furnace parameters with your quality requirements:

- If your primary focus is Perfect Pore Ordering: Prioritize the full duration of the heat treatment at the upper end of the temperature range (near 500 °C) to maximize grain uniformity.

- If your primary focus is Material Integrity: Ensure strictly controlled temperature ramp-ups to avoid thermal shock, keeping the steady state well below the aluminum melting point.

The quality of your final Anodic Aluminum Oxide substrate is determined before the anodization even begins, inside the annealing furnace.

Summary Table:

| Process Parameter | Role in AAO Preparation | Key Benefit |

|---|---|---|

| Temperature (400–500 °C) | Facilitates recrystallization and stress relief | Prevents melting while optimizing surface structure |

| Long Duration Heating | Allows for complete crystal lattice relaxation | Ensures a defect-free, stable aluminum substrate |

| Stress Elimination | Removes residual mechanical rolling tension | Prevents uneven expansion during anodization |

| Grain Homogenization | Creates uniform grain boundaries | Enables highly ordered, hexagonal pore growth |

Maximize Your Material Precision with KINTEK

The quality of your Anodic Aluminum Oxide (AAO) templates starts with perfect thermal conditioning. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnace systems specifically engineered for the high-precision requirements of aluminum annealing.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique temperature profiling and uniformity needs. Whether you are conducting research or scaling production, we bring the expertise to optimize your microstructure and ensure superior pore ordering.

Ready to elevate your lab's performance?

Contact KINTEK today to discuss your project!

Visual Guide

References

- Sheida Morsali, Mahmoud Moharrami. Synthesis and characterization of modified alumina membrane with carbon nano-tubes for separation of ethanol from water using sweeping gas membrane distillation. DOI: 10.1039/d5ra01731a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a sintering furnace used for? Fuse Powders into Dense, High-Performance Parts

- Why is precise temperature control in a drying oven critical for Li-SPAN battery cycle life? Ensure Peak Performance

- What are the advantages of using magnetron sputtering equipment compared to MBE? Scalable 2D Transistor Solutions

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair

- What are the temperature ranges for low, medium, and high-temperature industrial heating processes? Optimize Your Process with KINTEK

- What is the purpose of using a vacuum dryer for PU and AlN composite sheets? Enhance Thermal & Structural Integrity

- What is the purpose of using a high-vacuum pump system for NiTi thin films? Ensure Pure Stoichiometry & Performance

- What is the function of a laboratory drying oven in the preparation of solid bismuth molybdate materials? Expert Tips