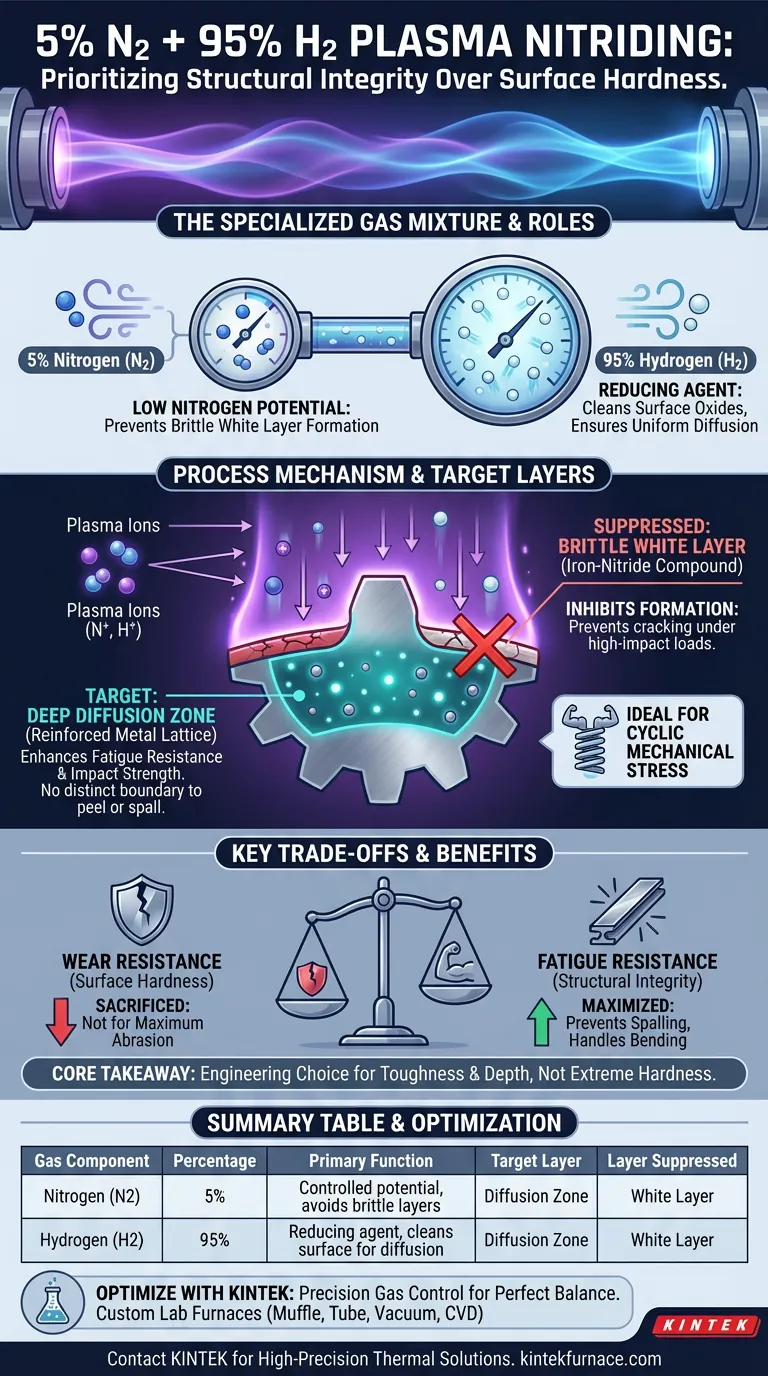

The primary role of a high-purity mixture containing 5% Nitrogen (N2) and 95% Hydrogen (H2) is to act as a specialized reactive medium that inhibits the formation of a brittle iron-nitride compound layer, widely known as the "white layer." By drastically lowering the nitrogen potential compared to standard mixtures, this specific ratio shifts the focus of the process away from surface coating and toward the creation of a deep, robust diffusion zone.

Core Takeaway: This gas mixture is an engineering choice designed to prioritize structural integrity over maximum surface hardness. By preventing the formation of a continuous white layer, the process utilizes alloying elements to enhance fatigue resistance and impact strength, effectively eliminating the risk of surface spalling under stress.

Controlling the Nitrogen Potential

The Function of Low Nitrogen Content

In standard plasma nitriding, nitrogen ratios are often higher (e.g., 30%) to build a hard compound layer.

However, a 5% Nitrogen ratio creates a significantly lower nitrogen potential.

This "starved" nitrogen atmosphere prevents the saturation required to form a continuous iron-nitride layer on the surface.

The Role of High Hydrogen Content

While nitrogen provides the hardening element, hydrogen acts as the cleaning and reducing agent.

With a 95% Hydrogen concentration, the atmosphere aggressively reduces surface oxides.

This ensures the workpiece surface remains chemically clean, allowing the limited nitrogen available to diffuse uniformly into the metal lattice rather than accumulating on top.

Targeting the Diffusion Layer

Bypassing the White Layer

The "white layer" is a hard but brittle compound zone that forms on the outermost surface of nitrided parts.

Using the 5% N2 / 95% H2 mixture effectively inhibits the formation of this continuous layer.

This is critical for applications where the brittleness of the white layer could lead to cracking or failure under high-impact loads.

Enhancing Fatigue Resistance

Instead of building a surface crust, this mixture promotes the development of a deep diffusion layer.

In this zone, nitrogen atoms interact with the steel's alloying elements to provide reinforcement.

This deep strengthening mechanism significantly improves the component's fatigue resistance and impact strength without creating a distinct boundary that could peel or spall.

Understanding the Trade-offs

Strength vs. Wear Resistance

It is vital to understand that this gas mixture is a calculated trade-off.

By suppressing the white layer, you sacrifice the extreme surface hardness and tribological (wear) properties that a thick compound layer provides.

This mixture is not ideal for parts requiring maximum abrasion resistance, but rather for those subjected to cyclic mechanical stress.

Process Precision

Using such a lean nitrogen mixture requires precise process control.

Variations in gas flow or plasma density can affect the uniformity of the diffusion layer.

Therefore, the gas control system must regulate the ratio accurately to maintain the desired nitrogen potential throughout the cycle.

Making the Right Choice for Your Goal

When selecting your gas ratio for plasma nitriding, align the mixture with the mechanical demands of the final component.

- If your primary focus is Fatigue Strength: Use the 5% N2 / 95% H2 mixture to inhibit the white layer and maximize the depth and toughness of the diffusion zone.

- If your primary focus is Wear Resistance: Opt for a higher nitrogen ratio (e.g., 25-30% N2) to encourage the formation of a hard, protective compound layer.

Select this high-hydrogen mixture when you need a part that can bend and endure cyclic loading without the risk of surface cracking.

Summary Table:

| Gas Component | Percentage | Primary Function |

|---|---|---|

| Nitrogen (N2) | 5% | Provides controlled nitriding potential to prevent brittle compound layers. |

| Hydrogen (H2) | 95% | Acts as a reducing agent to clean surface oxides and ensure uniform diffusion. |

| Target Layer | Diffusion Zone | Deeply strengthens the metal lattice to improve structural integrity and fatigue life. |

| Layer Suppressed | White Layer | Inhibits the hard but brittle iron-nitride crust to prevent surface spalling. |

Optimize Your Plasma Nitriding Process with KINTEK

Precision gas control is essential for achieving the perfect balance between fatigue resistance and surface hardness. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique metallurgical needs.

Ready to enhance your material properties and eliminate surface cracking? Contact KINTEK today to consult with our experts and find the ideal high-precision thermal solution for your lab or production line.

Visual Guide

References

- Magdalena Mokrzycka, Maciej Pytel. The influence of plasma nitriding process conditions on the microstructure of coatings obtained on the substrate of selected tool steels. DOI: 10.7862/rm.2024.1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Spark Plasma Sintering SPS Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is preventive maintenance on a furnace? A Proactive Strategy for Peak Performance

- What is the function of a rotary high-pressure autoclave in the synthesis of SSZ-13 zeolites? | Enhance Crystallinity

- Why is a high-pressure digestion tank essential for ZnO/rGO hydrothermal synthesis? Achieve superior interfacial coupling

- What are the advantages of using multi-stage laboratory sintering furnaces? Ensure Defect-Free Powder Metallurgy

- What is the purpose of using a thermal evaporation coating system? Enhancing I-V Testing Accuracy for Nanocomposites

- What is the primary function of an electric furnace in PBG melting? Expert Guide to Thermal Homogeneity

- How does the use of a stainless steel high-pressure autoclave affect ZnS/CeO2@CNT formation? Optimize Catalyst Growth

- Why is high-purity argon gas required during the calcination of TiO2/MoSe2 materials? Protect Your Sensor's Integrity