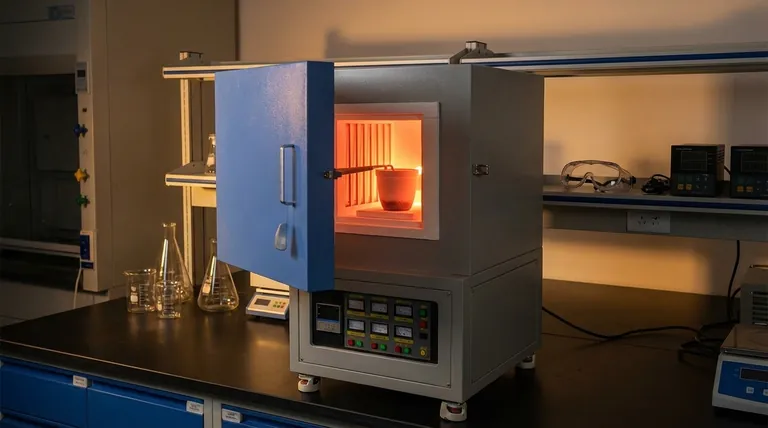

The primary function of an industrial-grade electric furnace in the preparation of phosphate glass (PBG) is to provide a rigorously controlled thermal environment that drives specific chemical and physical transitions. It does not merely melt the material; it executes a multi-stage heating profile designed to purify the raw batch and ensure total chemical homogeneity through convection.

The electric furnace acts as a precision reactor. Its role extends beyond liquefaction to include the critical removal of volatile impurities and the mechanical mixing of components via thermal currents, ensuring the final glass is uniform and defect-free.

The Two-Stage Thermal Processing Strategy

To understand the furnace's function, you must look at the specific temperature profile it executes. The process is distinct from simple heating; it is a staged operation.

Stage 1: Volatile Removal and Purification

The furnace typically targets an initial plateau of 500 °C.

At this specific temperature, the focus is not yet on melting the silica or phosphate network, but on purification.

The heat forces the release of volatile byproducts, specifically ammonia and water, from the raw materials. This "outgassing" phase is vital to prevent bubbles or structural weaknesses in the final glass.

Stage 2: High-Temperature Melting

Once volatiles are removed, the furnace ramps the temperature up to 1000 °C.

The material is held at this peak temperature for a specific duration, typically 60 minutes.

This sustained heat ensures the complete transition of the raw batch from solid to liquid, breaking down the crystalline structures of the ingredients.

Achieving Homogeneity via Convection

The furnace's function encompasses mixing as well as heating.

By maintaining high temperatures, the furnace facilitates thermal convection within the crucible.

These natural currents within the molten fluid physically mix the chemical components, ensuring the additives are distributed evenly throughout the glass matrix.

Critical Process Constraints

While the furnace is a robust tool, the quality of the output depends on adhering to the specific limitations of the process.

The Necessity of the Dwell Time

One cannot simply reach 1000 °C and immediately cool the glass.

The 60-minute hold time is a non-negotiable constraint required to allow thermal convection to do its work.

Shortening this window results in a "cordy" or streaky glass where the chemical composition varies from one millimeter to the next.

Temperature Staging Risks

The ramp rate between 500 °C and 1000 °C must be managed carefully.

If the furnace moves past the 500 °C stage before ammonia and water are fully evacuated, these gases become trapped in the viscous melt.

This leads to permanent inclusions and bubbles that ruin the optical and structural integrity of the PBG.

Making the Right Choice for Your Goal

When configuring your furnace protocols for phosphate glass, your priorities dictate your process control.

- If your primary focus is Optical Clarity: Prioritize the duration and stability of the 500 °C stage to ensure absolute removal of water and ammonia before melting begins.

- If your primary focus is Structural Uniformity: Ensure you strictly adhere to the 60-minute hold at 1000 °C to maximize the effects of thermal convection mixing.

Success in PBG preparation relies on treating the furnace not just as a heater, but as an instrument for precise chemical management.

Summary Table:

| Process Phase | Temperature | Duration | Primary Function |

|---|---|---|---|

| Purification | 500 °C | Until Outgassed | Removal of ammonia and water volatiles |

| Melting | 1000 °C | Transition | Complete liquefaction of the raw batch |

| Homogenization | 1000 °C | 60 Minutes | Mixing via thermal convection currents |

Elevate Your Material Processing with KINTEK

Precise thermal control is the difference between defective glass and a high-performance phosphate matrix. KINTEK provides the advanced heating technology required for rigorous PBG manufacturing.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet your unique dwell time and temperature staging needs.

Ready to optimize your glass melting protocols? Contact us today to find your custom furnace solution!

References

- Ragab Mahani, Ahlam M. Fathi. Electrical, optical, and electrochemical performances of phosphate-glasses-doped with ZnO and CuO and their composite with polyaniline. DOI: 10.1038/s41598-023-51065-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of placing a Nickel Mesh in a reactor? Maximizing Heat in Nickel-Hydrogen Systems

- What is the role of industrial thermometers in monitoring thermal stress? Ensure Safety via High-Precision Data

- How do industrial furnaces and quenching tanks affect TiCp/Fe composites? Optimize Heat Treatment Performance

- What are the functions of a rotary evaporator and a vacuum drying oven in LTO sol-gel? Optimize Your Synthesis Process

- What role does Iodine (I2) play as a transport agent in CVT for FexTaSe2? Unlock Efficient Single Crystal Growth

- Why is a low-temperature annealing treatment necessary for porous gold microspheres? Ensure Structural Integrity

- How does a vacuum thermal evaporation system ensure the quality of Bismuth Telluride thin films? Expert Insights

- Why is an 800 °C heat treatment for Ti6Al4V additive manufacturing necessary? Unlock Ductility & Relieve Stress