Structural integrity is the primary driver. Low-temperature annealing is a critical stabilization step necessary to eliminate the microscopic defects and residual stresses that accumulate during the aggressive chemical dealloying process. By subjecting the material to moderate heat, you allow the porous gold ligaments to coarsen and round, which fortifies the microspheres against structural collapse during subsequent bonding and optimizes their electrical conductivity.

Chemical dealloying leaves porous architectures inherently fragile and stress-prone. Low-temperature annealing acts as a mandatory healing process, reinforcing the gold ligaments to ensure mechanical survival while enhancing electrical performance.

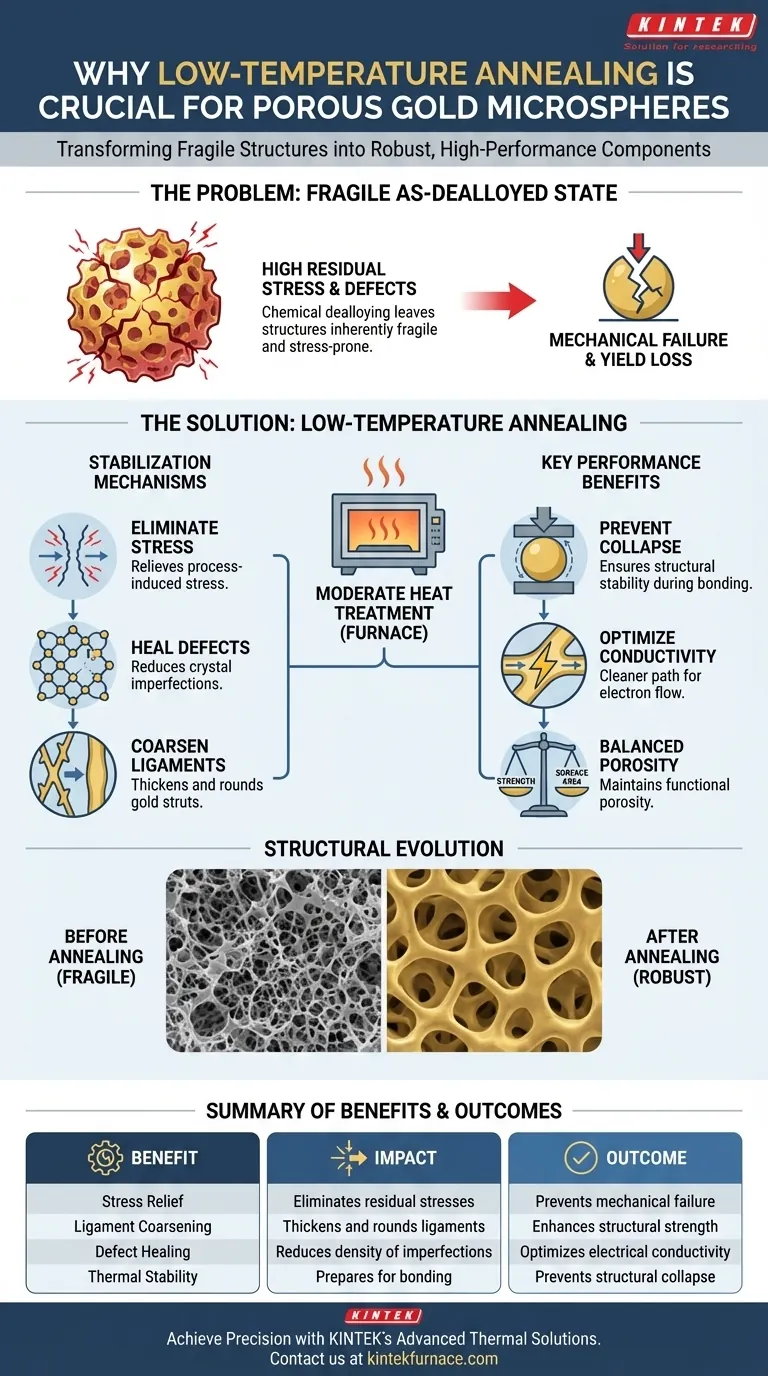

The Mechanism of Stabilization

Eliminating Process-Induced Stress

Chemical dealloying is a harsh subtractive process. As less noble metals are chemically removed, the remaining gold atoms are forced to rearrange rapidly.

This leaves the resulting porous structure riddled with residual stresses and microscopic defects. Without thermal treatment, these internal stresses act as fault lines that can lead to immediate mechanical failure.

Healing Microscopic Defects

The annealing furnace provides the thermal energy required to heal these atomic-level imperfections.

By reducing the density of crystal defects, the material moves toward a lower energy state. This relaxation is essential for transforming a fragile, chemically roughened structure into a stable, engineered material.

Structural Evolution and Performance

Strengthening via Ligament Coarsening

During the low-temperature anneal, the gold ligaments—the tiny struts that make up the porous network—undergo a physical transformation.

The heat causes these ligaments to coarsen and round. This change in geometry significantly increases the mechanical strength of individual struts, making the overall microsphere more robust.

Preventing Collapse During Bonding

The ultimate test for these microspheres often occurs during downstream assembly, specifically bonding processes that involve pressure or heat.

Unannealed spheres often suffer from structural collapse under these conditions. The coarsening effect of annealing ensures the microspheres possess the mechanical stability required to withstand bonding pressures without crushing.

Optimizing Electrical Conductivity

Beyond mechanical strength, annealing directly impacts electrical performance.

The elimination of scattering centers (defects) and the thickening of the gold ligaments provide a cleaner path for electron flow. This results in optimized electrical conductivity, a critical parameter for conductive adhesive applications.

Understanding the Trade-offs

Balancing Strength and Surface Area

While annealing is necessary, the "low-temperature" aspect is a deliberate constraint.

The goal is to induce enough ligament coarsening to gain strength, but not so much that you destroy the porous nature of the material. Excessive heat or time in the furnace would lead to over-coarsening, closing the pores and reducing the high surface area that makes porous gold valuable in the first place.

The Cost of Skipping This Step

Omitting the annealing phase might seem like a way to save processing time, but the cost is usually yield loss.

Microspheres that skip this step retain high internal energy and fragility. This typically results in inconsistent electrical performance and a high rate of mechanical failure during the final assembly or bonding stages.

Making the Right Choice for Your Goal

To ensure your porous gold microspheres perform as intended, apply the annealing process based on your specific application requirements:

- If your primary focus is Assembly Reliability: Prioritize this annealing step to prevent structural collapse during the pressure and heat of the bonding process.

- If your primary focus is Electrical Performance: Utilize the heat treatment to heal defects and coarsen ligaments, which is essential for maximizing conductivity.

Low-temperature annealing is not merely a finishing step; it is the bridge that transforms a fragile chemical product into a robust functional component.

Summary Table:

| Benefit of Annealing | Impact on Porous Gold Microspheres | Primary Outcome |

|---|---|---|

| Stress Relief | Eliminates residual stresses from chemical dealloying | Prevents mechanical failure |

| Ligament Coarsening | Thickens and rounds gold ligaments | Enhances structural strength |

| Defect Healing | Reduces density of crystal imperfections | Optimizes electrical conductivity |

| Thermal Stability | Prepares structure for high-pressure bonding | Prevents structural collapse |

| Surface Area Control | Balances coarsening with pore preservation | Maintains functional porosity |

Achieve precision and reliability in your material stabilization with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet the delicate temperature requirements of your porous gold and high-tech lab processes. Don't compromise your yield; ensure every microsphere meets the highest standards for conductivity and mechanical strength. Contact KINTEK today to find the perfect high-temp furnace for your unique needs.

Visual Guide

References

- Li Zhang, Shaolong Tang. Novel Porous Gold Microspheres Anisotropic Conductive Film (PGMS‐ACF) with High Compression Ratio for Flip Chip Packaging. DOI: 10.1002/aelm.202500045

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is high raw material purity essential for magnesium alloy research? Ensure Precise Thermodynamic Data Quality

- Why is 800 °C necessary for NCNTs? Unlock Superior Conductivity and Ion Transport

- How does rapid quenching after diffusion treatment affect the material properties of the silicon structure? Lock-in Vital Phases

- How does a reactor system control chlorine sources in oxychlorination? Master Catalyst Regeneration Control

- What is the primary role of the Thermal Oxidation (TO) process in Ti-6Al-4V ELI alloy? Enhancing Hardness and Wear

- What is tempering, and when is it used? Optimize Metal Toughness and Durability

- What is the purpose of adding calcium fluoride (CaF2) in magnesium production? Accelerate Your Vacuum Carbothermal Reduction

- Why is precise molar measurement of metal nitrates required during the preparation of high-entropy oxide precursor solutions? Ensure HEO Stability & Purity