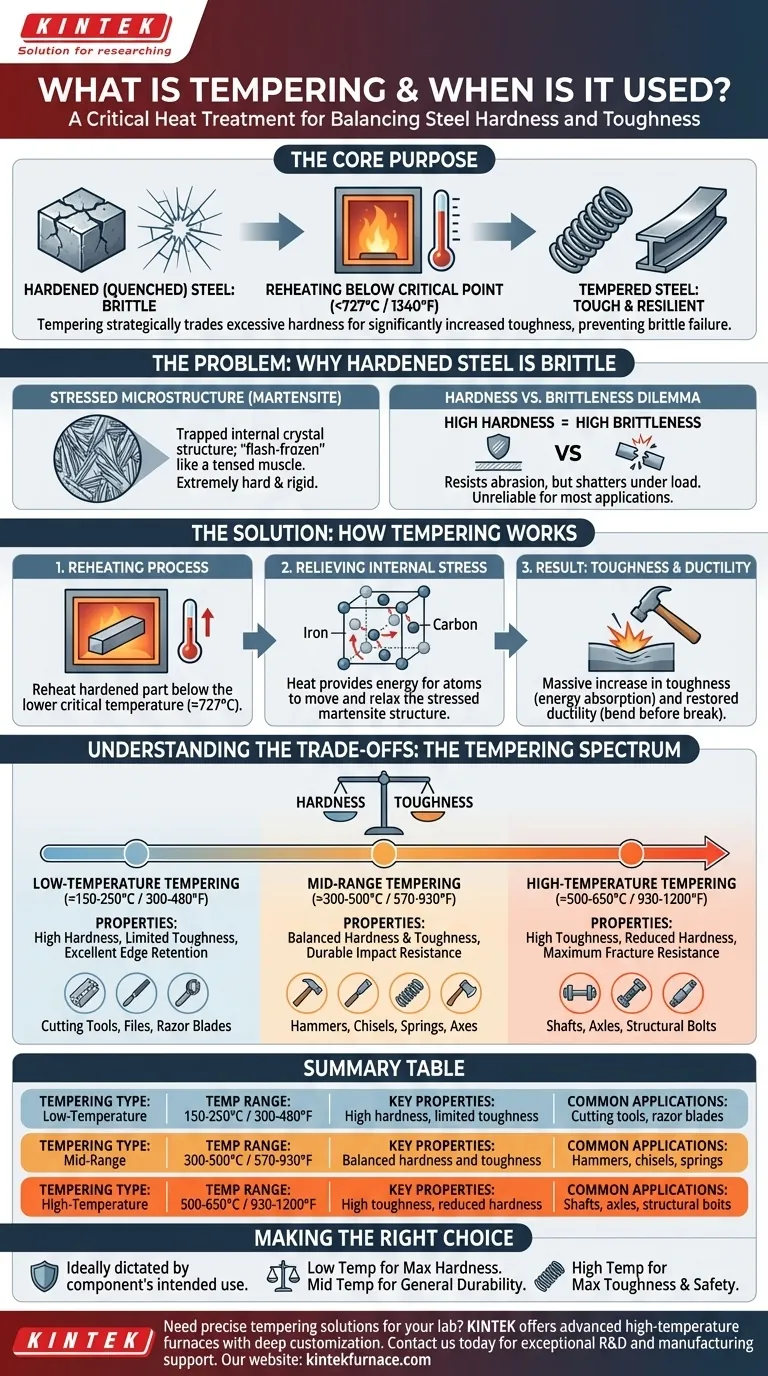

In simple terms, tempering is a heat treatment process used after a metal has been hardened (typically through quenching). It involves reheating the component to a specific temperature below its critical point and holding it there for a set time, which reduces the extreme brittleness caused by hardening and significantly increases its toughness.

The core purpose of tempering is to make hardened steel useful. It strategically trades a small amount of hardness, which is often excessive after quenching, for a critical increase in toughness, preventing the material from shattering under stress or impact.

The Problem: Why Hardened Steel is Brittle

To understand tempering, you must first understand the problem it solves. Hardening a piece of steel through quenching creates a material that is often too brittle for practical use.

The Stressed Microstructure of Quenched Steel

When steel is heated to a high temperature and then rapidly cooled (quenched), its internal crystal structure is trapped in a highly stressed, needle-like formation known as martensite.

This martensitic structure is extremely hard and rigid. Think of it as a muscle that has been flash-frozen while fully tensed—it's powerful but has no flexibility and is prone to tearing.

The Hardness vs. Brittleness Dilemma

This extreme hardness comes at a cost: brittleness. A fully hardened, untempered piece of steel behaves much like glass. While it can resist scratching and abrasion (hardness), it will shatter catastrophically when struck or put under sudden load (brittleness).

For nearly all applications, from a knife blade to a structural bolt, this brittleness makes the part unreliable and dangerous.

The Solution: How Tempering Works

Tempering is the essential second step that modifies the martensite, relieving the internal stresses and transforming the material's properties.

The Reheating Process

The process involves reheating the hardened part to a precise temperature, always below the lower critical temperature of the steel (around 727°C or 1340°F). The exact temperature chosen is the most critical variable in the process.

Relieving Internal Stress

This application of heat gives the trapped carbon atoms just enough energy to move slightly within the steel's iron crystal lattice. This movement allows the highly stressed martensite structure to relax and reform into new microstructures (like tempered martensite or bainite).

This process doesn't reverse the hardening; it refines it. It’s like gently warming that tensed, frozen muscle, allowing it to relax just enough to regain its resilience.

The Result: Toughness and Ductility

The primary outcome of tempering is a massive increase in toughness—the material's ability to absorb energy and deform without fracturing. It also restores some ductility, allowing the part to bend before it breaks.

Understanding the Trade-offs: The Tempering Spectrum

The specific temperature used for tempering dictates the final balance between hardness and toughness. This relationship is a direct trade-off.

Low-Temperature Tempering (approx. 150-250°C / 300-480°F)

This preserves the majority of the hardness while relieving just enough stress to prevent catastrophic failure. The result is a material with excellent wear resistance but limited toughness.

This is ideal for components like cutting tools, files, and razor blades, where edge retention is the absolute priority.

Mid-Range Tempering (approx. 300-500°C / 570-930°F)

As the temperature increases, more hardness is traded for a significant gain in toughness. This creates a balanced, durable material that can withstand repeated impacts.

This range is used for tools like hammers, chisels, springs, and axes, which need a combination of a reasonably hard working edge and the toughness to avoid chipping or breaking.

High-Temperature Tempering (approx. 500-650°C / 930-1200°F)

Tempering at these higher temperatures results in the greatest toughness and ductility at the expense of hardness. The material will be much softer but highly resistant to fracture.

This is essential for high-stress components like shafts, axles, and structural bolts, where the ability to bend or stretch under extreme load is a critical safety feature.

Making the Right Choice for Your Application

The ideal tempering temperature is dictated entirely by the component's intended use.

- If your primary focus is maximum hardness and wear resistance: Opt for a low-temperature temper to create a part that holds an edge but may be brittle.

- If your primary focus is impact resistance and general durability: Use a mid-range temper to achieve a balanced profile of good hardness and reliable toughness.

- If your primary focus is maximum toughness and safety: Employ a high-temperature temper for a part that will deform and bend long before it ever fractures.

Ultimately, tempering is the critical control knob that allows you to transform a hard but useless material into a component perfectly optimized for its task.

Summary Table:

| Tempering Type | Temperature Range | Key Properties | Common Applications |

|---|---|---|---|

| Low-Temperature | 150-250°C / 300-480°F | High hardness, limited toughness | Cutting tools, razor blades |

| Mid-Range | 300-500°C / 570-930°F | Balanced hardness and toughness | Hammers, chisels, springs |

| High-Temperature | 500-650°C / 930-1200°F | High toughness, reduced hardness | Shafts, axles, structural bolts |

Need precise tempering solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental requirements are met. Contact us today to enhance your material processing efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation