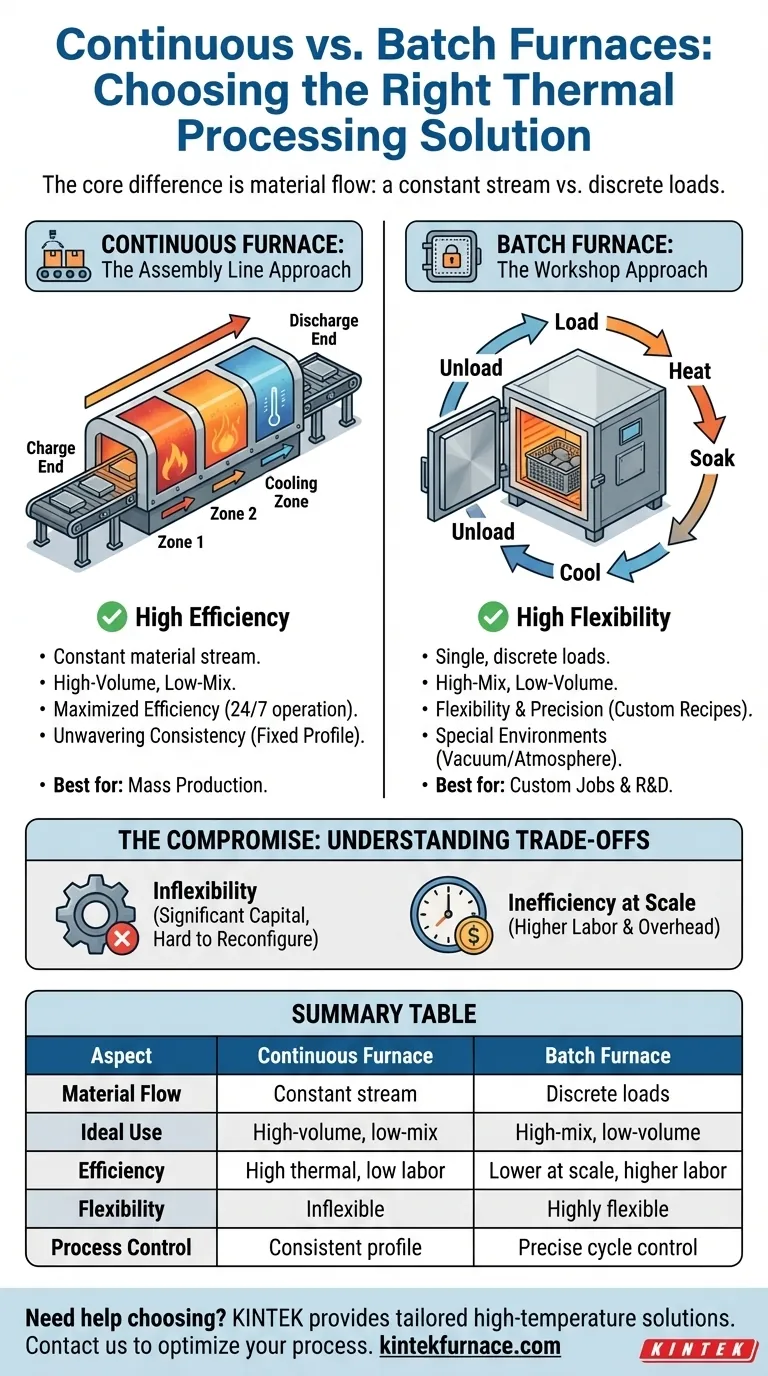

At its core, the difference between a continuous and a batch furnace is a matter of material flow. A continuous furnace processes a constant stream of material that moves through distinct heating and cooling zones, much like an assembly line. In contrast, a batch furnace processes a single, discrete load of material that is placed inside, treated according to a specific recipe, and then removed before the next load can begin.

Choosing between these two technologies is a fundamental strategic decision. It forces a choice between the high-volume efficiency of a continuous system and the high-mix flexibility of a batch system. Your production goals, not the furnace technology itself, should dictate the correct path.

The Operational Model: Flow vs. Static

The fundamental difference in how these furnaces operate dictates their ideal applications, costs, and overall efficiency.

Continuous Furnaces: The Assembly Line Approach

A continuous furnace operates without stopping. Components are constantly fed into the charge end, travel through the furnace on a conveyor, and are discharged at the other end after treatment.

Each section of the furnace maintains a specific temperature, creating a pre-set thermal profile. This design is optimized for one specific, repeatable process.

Batch Furnaces: The Workshop Approach

A batch furnace functions as a sealed chamber. An entire load, or "batch," of components is placed inside, the door is closed, and the entire chamber is brought through a precise heating and cooling cycle.

Once the process is complete, the furnace must often cool before the finished batch is removed and a new one is loaded. This makes them inherently cyclical rather than constant.

When to Choose a Continuous Furnace

Continuous furnaces are specialists, designed for large-scale, consistent production runs where efficiency is the primary driver.

High-Volume, Low-Mix Production

These furnaces excel when you need to process thousands or millions of identical parts. They are the standard for mass production industries.

Maximizing Efficiency and Reducing Labor

By operating 24/7, continuous furnaces achieve very high thermal efficiency and significantly reduce the labor cost per unit. The process is highly automated, requiring monitoring rather than constant hands-on work.

Unwavering Process Consistency

Because the thermal profile is fixed, every component passing through the furnace receives the exact same heat treatment. This guarantees a high degree of uniformity and quality control for mass-produced items.

When to Choose a Batch Furnace

Batch furnaces are generalists, offering the flexibility to handle a wide variety of jobs and precise control over each one.

High-Mix, Low-Volume Production

If your production involves frequent changes—different part sizes, varying material compositions, or unique heat treatment cycles—a batch furnace is superior. Each batch can have its own custom recipe.

Precision and Process Customization

Batch systems offer unparalleled control over heating rates, soaking times, and cooling profiles. This precision is critical for complex metallurgical treatments or when working with sensitive materials.

Suitability for Special Environments

Their sealed-chamber design makes batch furnaces ideal for processes requiring controlled atmospheres, such as inert gases or high-purity vacuum environments common in aerospace and electronics.

Understanding the Trade-offs

Neither furnace type is universally superior. The choice involves accepting a clear set of compromises.

The Inflexibility of Continuous Furnaces

A continuous furnace is a significant capital investment optimized for a single task. It is highly inefficient if run below capacity or if stopped and started frequently. Reconfiguring one for a new process is a major and costly undertaking.

The Inefficiency of Batch Furnaces at Scale

While highly flexible, batch furnaces are less efficient for mass production. The time spent loading, unloading, and cycling temperatures between batches adds significant overhead and labor cost when applied to a high-volume part.

Making the Right Choice for Your Goal

Select your furnace based on your business's primary production model.

- If your primary focus is mass production and lowest cost-per-unit: A continuous furnace is the definitive choice for its unmatched efficiency and automation at scale.

- If your primary focus is flexibility and process control: A batch furnace provides the essential versatility to handle varied parts and custom treatment cycles.

- If your primary focus is R&D or specialty manufacturing: The precise, customizable environment of a batch furnace is necessary for development and complex jobs.

By aligning your furnace choice with your core production strategy, you ensure your heat treatment process becomes a competitive advantage, not a bottleneck.

Summary Table:

| Aspect | Continuous Furnace | Batch Furnace |

|---|---|---|

| Material Flow | Constant stream, assembly-line | Discrete loads, static chamber |

| Ideal Use | High-volume, low-mix production | High-mix, low-volume production |

| Efficiency | High thermal efficiency, low labor cost | Lower efficiency at scale, higher labor overhead |

| Flexibility | Inflexible, optimized for one process | Highly flexible, customizable recipes |

| Process Control | Consistent thermal profile | Precise control over heating/cooling cycles |

Struggling to choose the right furnace for your lab's unique needs? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your experimental requirements. Whether you need high-volume efficiency or high-mix flexibility, we can help optimize your heat treatment process. Contact us today to discuss how our tailored solutions can enhance your productivity and results!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity