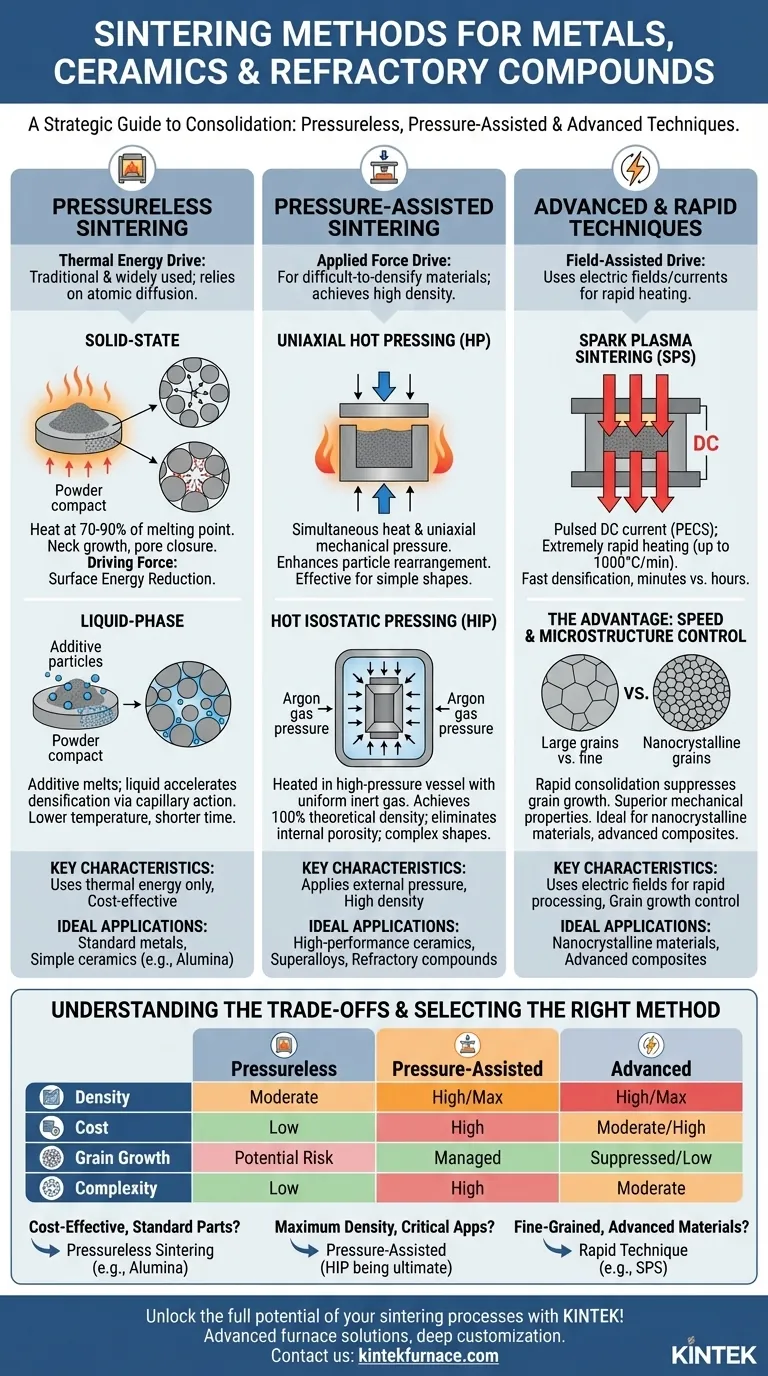

At its core, sintering is a thermal treatment process that transforms a powder compact into a dense, solid object. While the goal is consolidation, the primary methods to achieve it vary significantly based on whether external pressure is applied. The main categories are pressureless sintering (including solid-state and liquid-phase), pressure-assisted sintering (like Hot Pressing and Hot Isostatic Pressing), and advanced field-assisted techniques.

The choice of a sintering method is fundamentally a strategic trade-off. You are balancing the need for maximum final density against the constraints of processing time, cost, and the inherent properties of the material you are working with.

The Foundation: Pressureless Sintering

Pressureless sintering is the most traditional and widely used method. It relies solely on thermal energy to drive the densification process, where atomic diffusion reduces the surface area and porosity of the powder compact.

How Solid-State Sintering Works

In this process, a shaped powder component (a "green body") is heated to a high temperature, typically 70-90% of its melting point. At this temperature, atoms migrate between particles, causing the necks between them to grow and the pores to shrink and eventually close.

The driving force is the reduction of surface energy. It is analogous to how small soap bubbles merge to form larger ones to minimize total surface area.

The Role of Liquid-Phase Sintering

This is a variation where a small amount of a secondary material, which has a lower melting point, is added to the main powder. During heating, this additive melts and forms a liquid phase that wets the solid particles.

The liquid accelerates densification by providing a fast diffusion path for atoms and by pulling particles together through capillary action. This often allows for lower sintering temperatures and shorter processing times compared to pure solid-state sintering.

Applying Force: Pressure-Assisted Sintering

For materials that are difficult to densify or require near-perfect density, external pressure is applied simultaneously with heat. This category directly includes the methods mentioned in your query, providing a more effective driving force for consolidation.

Uniaxial Hot Pressing (HP)

In Hot Pressing, the powder is placed in a die and simultaneously heated while mechanical pressure is applied along a single axis (uniaxially). This force significantly enhances the particle rearrangement and plastic deformation mechanisms.

This method is highly effective for producing simple shapes like discs or plates with high density. However, the density can be less uniform due to friction with the die walls.

Hot Isostatic Pressing (HIP)

HIP is a more advanced technique where the component is heated in a high-pressure vessel. An inert gas, typically Argon, applies uniform, isostatic (equal from all directions) pressure to the part.

Because the pressure is perfectly uniform, HIP can produce components with 100% theoretical density, eliminate internal porosity, and create complex shapes. It is the gold standard for critical applications in aerospace and medical implants.

Advanced & Rapid Techniques: Field-Assisted Sintering

Modern methods use electric fields or currents to dramatically accelerate the heating and sintering process. These techniques are game-changers for advanced materials.

Spark Plasma Sintering (SPS)

Also known as Pulsed Electric Current Sintering (PECS), SPS passes a high-amperage pulsed DC current directly through the powder and the conductive die. This creates extremely rapid heating rates (up to 1000°C/min).

The high heating rates and the effects of the electric current dramatically accelerate densification, allowing for full density to be achieved in minutes instead of hours.

The Advantage: Speed and Microstructure Control

The primary benefit of methods like SPS is the ability to consolidate powders so quickly that grain growth is suppressed. Since fine grains often lead to superior mechanical properties (like strength and hardness), these methods are ideal for producing high-performance nanocrystalline ceramics, metals, and composites.

Understanding the Trade-offs

Choosing a method requires an objective analysis of its benefits and drawbacks. There is no universally "best" option.

Density vs. Cost

Pressureless sintering is the cheapest and most scalable method but may not achieve full density for difficult materials. In contrast, HIP achieves maximum density but is by far the most expensive and complex process due to the high-pressure equipment required.

Grain Growth: The Unwanted Side Effect

The longer a material is held at a high temperature, the more its microscopic grains will grow. While this helps close pores, excessive grain growth can severely degrade mechanical properties. This is the primary trade-off in conventional sintering.

Geometry and Complexity

Pressureless sintering and HIP are excellent for creating complex, near-net-shape parts. Uniaxial Hot Pressing is generally limited to simple, symmetric geometries due to the directional nature of the applied force.

Selecting the Right Method for Your Material

Your choice should be dictated by your material's properties and your final performance requirements.

- If your primary focus is cost-effective production of standard metals or simple ceramics (e.g., Alumina): Pressureless sintering is often the most practical and economical choice.

- If your primary focus is achieving maximum density in high-performance ceramics, superalloys, or refractory compounds: Pressure-assisted methods are necessary, with HIP being the ultimate choice for eliminating all residual porosity.

- If your primary focus is preserving a fine-grained or nanostructured microstructure in advanced materials: A rapid technique like Spark Plasma Sintering (SPS) is the superior option.

Ultimately, understanding the interplay between temperature, time, pressure, and your material's intrinsic behavior empowers you to make the optimal processing decision.

Summary Table:

| Method Type | Key Characteristics | Ideal Applications |

|---|---|---|

| Pressureless Sintering | Uses thermal energy only; cost-effective | Standard metals, simple ceramics like Alumina |

| Pressure-Assisted Sintering | Applies external pressure for high density | High-performance ceramics, superalloys, refractory compounds |

| Field-Assisted Sintering | Uses electric fields for rapid processing | Nanocrystalline materials, advanced composites |

Unlock the full potential of your sintering processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're working with metals, ceramics, or refractory compounds, we help you achieve superior density, microstructure control, and cost efficiency. Contact us today to discuss how our tailored solutions can elevate your research and production!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- What is a hot press used for? Fabricate Dense, High-Performance Materials