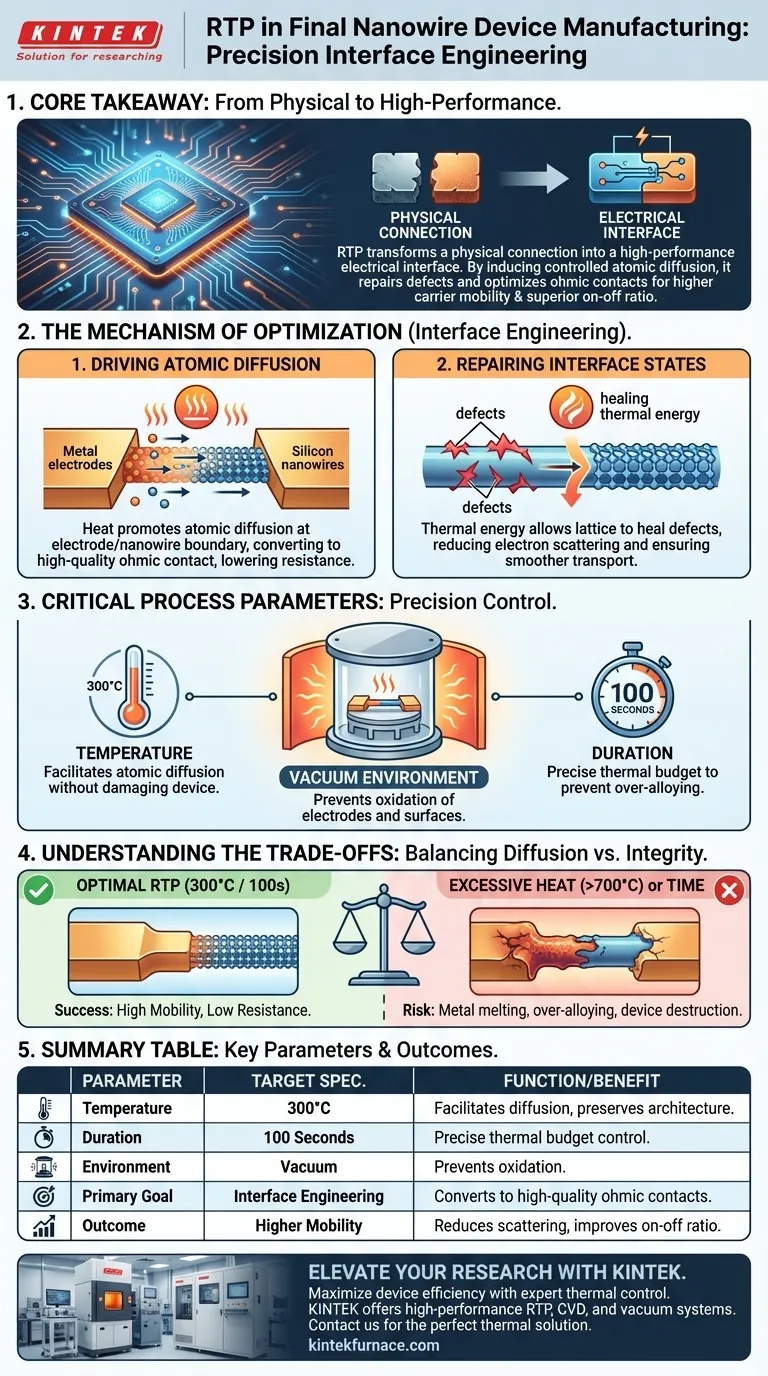

Rapid Thermal Processing (RTP) functions as a precise finishing step by subjecting the completed device to a vacuum anneal at 300°C for exactly 100 seconds. This controlled thermal burst serves to finalize the electrical integration of the device, specifically targeting the connection points between the metal electrodes and the nanowires.

Core Takeaway RTP transforms a physical connection into a high-performance electrical interface. By inducing controlled atomic diffusion, it repairs fabrication defects and optimizes ohmic contacts, directly resulting in higher carrier mobility and a superior on-off ratio for the transistor.

The Mechanism of Optimization

The primary goal of RTP in the final stages is not material synthesis, but interface engineering.

Driving Atomic Diffusion

The process uses heat to promote atomic diffusion at the boundary where the metal electrodes meet the silicon nanowires.

This diffusion lowers the resistance at the junction, converting the interface into a high-quality ohmic contact. Without this step, the barrier to electron flow would be too high, severely limiting device performance.

Repairing Interface States

Fabrication processes often leave behind structural defects or "interface states" on the nanowire surface.

The RTP cycle acts as a healing mechanism. The thermal energy allows the lattice to settle and repair these states, reducing electron scattering and ensuring smoother carrier transport.

Critical Process Parameters

Precision is the defining characteristic of this stage. Unlike bulk furnace annealing, RTP provides rapid heating and cooling rates to manage the "thermal budget."

Temperature and Time Constraints

The standard protocol for the final stage is a 300°C anneal for 100 seconds.

This specific window is critical; it provides enough energy to improve the contact but is short and cool enough to prevent unwanted diffusion or damage to other device layers.

The Role of Vacuum Environment

Performing this anneal in a vacuum is essential.

A vacuum environment prevents the oxidation of the metal electrodes and the nanowire surface during heating, ensuring that the improvements in conductivity are not negated by the formation of insulating oxide layers.

Understanding the Trade-offs

While RTP is a versatile tool capable of reaching much higher temperatures, applying it correctly in the final stage requires restraint.

High-Temperature Risks

RTP systems are capable of temperatures exceeding 700°C, often used in earlier stages for crystallizing materials like MoS2 or driving dopants.

However, utilizing such high temperatures on a completed device would be catastrophic. Excessive heat at the final stage could cause metal electrodes to melt, diffuse entirely into the nanowire, or degrade the delicate device architecture.

Balancing Diffusion vs. Integrity

The success of the process relies on a delicate balance.

Insufficient time or temperature results in poor contact resistance (Schottky barriers). Conversely, exceeding the 300°C / 100s limit risks over-alloying the metal with the semiconductor, physically consuming the nanowire and destroying the device.

Making the Right Choice for Your Goal

To maximize the efficacy of RTP in nanowire device fabrication, tailor your parameters to the specific stage of development.

- If your primary focus is Electrical Efficiency: Ensure the anneal reaches the full 300°C to guarantee sufficient atomic diffusion for low-resistance ohmic contacts.

- If your primary focus is Device Reliability: Strictly adhere to the 100-second duration limit to prevent thermal stress or over-diffusion that compromises the physical structure.

Summary: The RTP phase is the bridge between a fabricated structure and a functional electronic device, leveraging precise thermal control to unlock the full potential of carrier mobility.

Summary Table:

| Process Parameter | Target Specification | Function/Benefit |

|---|---|---|

| Temperature | 300°C | Facilitates atomic diffusion without damaging device architecture |

| Duration | 100 Seconds | Precise thermal budget control to prevent over-alloying |

| Environment | Vacuum | Prevents oxidation of electrodes and nanowire surfaces |

| Primary Goal | Interface Engineering | Converts junctions into high-quality ohmic contacts |

| Outcome | Higher Mobility | Reduces electron scattering and improves on-off ratios |

Elevate Your Nanowire Research with KINTEK

Maximize your device efficiency with precision thermal control. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance RTP, CVD, and vacuum systems designed for the most demanding lab requirements. Whether you are optimizing ohmic contacts or exploring new material boundaries, our customizable high-temperature furnaces provide the reliability you need.

Ready to refine your fabrication process? Contact KINTEK experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Lei Wu, Linwei Yu. Step-necking growth of silicon nanowire channels for high performance field effect transistors. DOI: 10.1038/s41467-025-56376-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is precise temperature control necessary in a drying oven for MOF precursors? Ensure Nanopore Integrity

- What are the equipment requirements for high-temperature furnaces during magnetic biochar synthesis? Find the key specs.

- How does the secondary heat treatment process improve battery performance? Optimize SHPC/N-CNT Composites Today

- Why is X-ray diffraction (XRD) required for lithium iron phosphate synthesis? Ensuring Phase Purity & Structure

- Why is a laboratory vacuum oven utilized for ZnO-FL drying? Preserving Delicate Nanoparticle Morphologies

- Why are ceramic materials preferred for dental restorations? Discover Their Aesthetic, Strength, and Biocompatibility Benefits

- How does precise heating rate control affect nitrogen-doped carbon synthesis? Master Thermal Ramp for Quality Materials

- Why is temperature control precision critical for a sample heating furnace? Master Ti-V-Cr Alloy Oxidation Kinetics