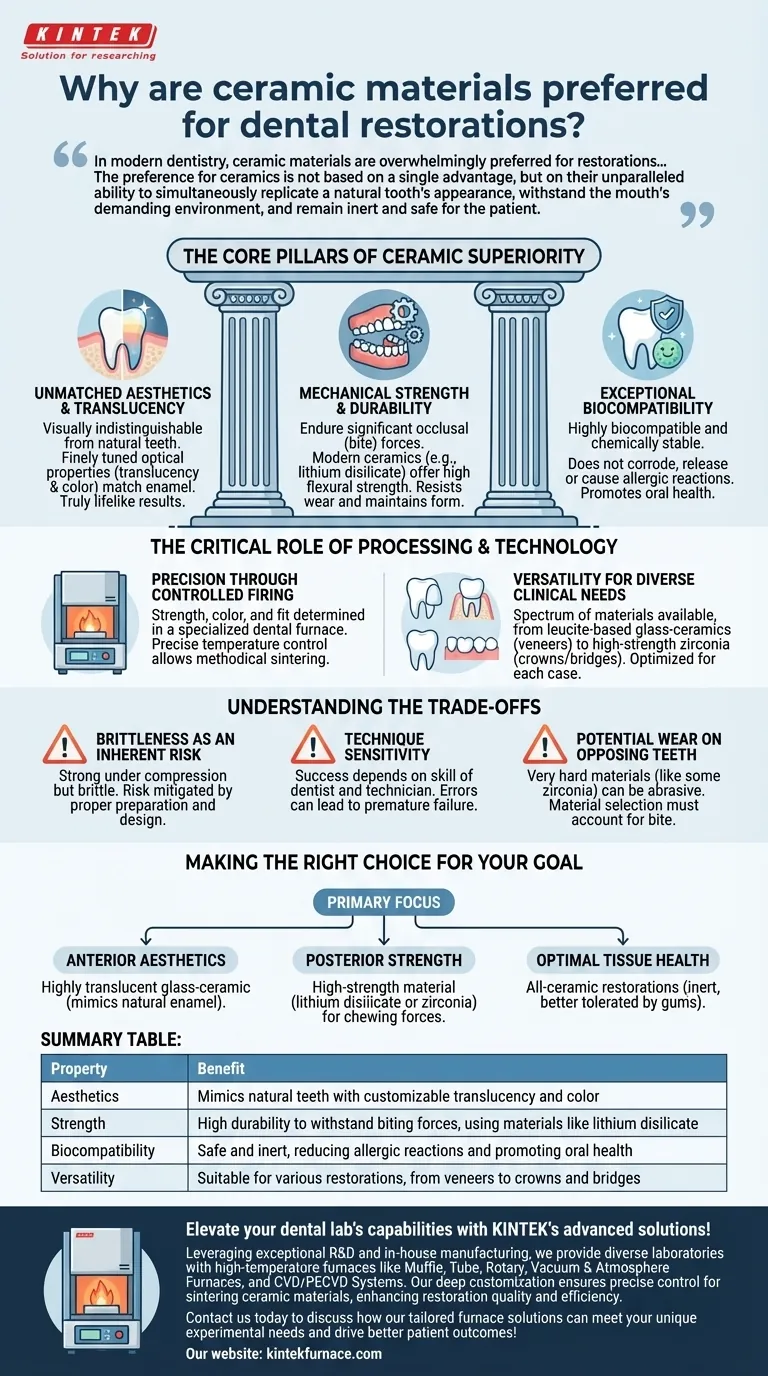

In modern dentistry, ceramic materials are overwhelmingly preferred for restorations due to their unique combination of properties. They offer superior aesthetics that mimic natural teeth, exceptional strength to withstand biting forces, and excellent biocompatibility, ensuring they are safe and well-tolerated by the body.

The preference for ceramics is not based on a single advantage, but on their unparalleled ability to simultaneously replicate a natural tooth's appearance, withstand the mouth's demanding environment, and remain inert and safe for the patient.

The Core Pillars of Ceramic Superiority

To understand why ceramics dominate, we must look at how they address the three fundamental requirements of any dental restoration: appearance, function, and health.

Unmatched Aesthetics and Translucency

A successful restoration must be visually indistinguishable from a natural tooth. Ceramics excel here because their optical properties, like translucency and color, can be finely tuned to match natural enamel.

This is not possible with metal or amalgam alternatives. The ability to customize the shade and light-reflecting qualities of a ceramic crown or veneer is what allows for a truly lifelike result.

Mechanical Strength and Durability

The mouth is a harsh environment, and restorations must endure significant occlusal (bite) forces daily. Modern dental ceramics are engineered for this purpose.

Materials like lithium disilicate offer high flexural strength, making them durable enough for both front and back teeth. They resist wear and maintain their form and function for many years when properly designed and placed.

Exceptional Biocompatibility

Biocompatibility refers to a material's ability to exist in the body without causing harm or an adverse reaction. Ceramics are highly biocompatible and chemically stable.

Unlike some metals, they do not corrode, release ions, or cause allergic reactions in the surrounding gum tissue. This inert nature promotes better long-term oral health.

The Critical Role of Processing and Technology

The properties of the final ceramic restoration are not solely dependent on the raw material. They are unlocked through highly controlled fabrication processes.

Precision Through Controlled Firing

The strength, color, and fit of a ceramic restoration are determined during the firing process in a specialized dental furnace.

Precise temperature control is critical. It allows dental technicians to sinter the ceramic particles metodaically, achieving the desired density and translucency without compromising structural integrity.

Versatility for Diverse Clinical Needs

There is no single "ceramic" for all situations. The field offers a spectrum of materials, from aesthetically-focused leucite-based glass-ceramics for veneers to high-strength zirconia for full-coverage crowns and bridges.

This versatility allows a clinician to select a material optimized for the specific demands of each case, whether the priority is appearance in the front of the mouth or brute strength in the back.

Understanding the Trade-offs

While ceramics are a superior choice, they are not without technical considerations. Objectivity requires acknowledging their limitations.

Brittleness as an Inherent Risk

Ceramics are very strong under compression but can be brittle and may fracture under specific types of tension or sharp impact. This risk is mitigated by proper tooth preparation and restoration design.

Technique Sensitivity

The success of a ceramic restoration is highly dependent on the skill of both the dentist and the laboratory technician. An improperly prepared tooth, a poor impression, or errors during fabrication can lead to premature failure.

Potential Wear on Opposing Teeth

Some very hard ceramic materials, like early forms of zirconia, can be abrasive and cause wear on the opposing natural teeth over time. Material selection must account for the patient's entire bite scheme.

Making the Right Choice for Your Goal

Selecting the correct material is a clinical decision based on balancing aesthetics, strength, and the location of the restoration.

- If your primary focus is anterior aesthetics: A highly translucent glass-ceramic is often the best choice to perfectly mimic natural enamel.

- If your primary focus is posterior strength: A high-strength material like lithium disilicate or zirconia is necessary to withstand heavy chewing forces.

- If your primary focus is optimal tissue health: All-ceramic restorations are superior to metal-based options, as they do not corrode and are better tolerated by the gums.

By understanding these material properties and their clinical implications, you can restore both long-term function and patient confidence.

Summary Table:

| Property | Benefit |

|---|---|

| Aesthetics | Mimics natural teeth with customizable translucency and color |

| Strength | High durability to withstand biting forces, using materials like lithium disilicate |

| Biocompatibility | Safe and inert, reducing allergic reactions and promoting oral health |

| Versatility | Suitable for various restorations, from veneers to crowns and bridges |

Elevate your dental lab's capabilities with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise control for sintering ceramic materials, enhancing restoration quality and efficiency. Contact us today to discuss how our tailored furnace solutions can meet your unique experimental needs and drive better patient outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations