Flash sintering fundamentally transforms the production of KNN ceramics by replacing prolonged thermal soaking with an instantaneous electrical event. By leveraging the synergy of a DC electric field and a thermal field, this system reduces sintering times from several hours to mere seconds.

Core Takeaway The decisive advantage of flash sintering for KNN ceramics is its ability to reach high densification in seconds, effectively "freezing" the material structure. This prevents the volatilization of alkali metals and grain coarsening inherent to traditional slow-heating methods, securing superior piezoelectric properties.

The Mechanism of Rapid Densification

Synergy of Thermal and Electric Fields

Traditional sintering relies solely on thermal energy conducting from the surface inward. Flash sintering introduces a DC electric field alongside the thermal field.

This combination triggers a rapid densification event. The electric field acts directly on the material, accelerating mass transport mechanisms far beyond what thermal energy alone can achieve.

From Hours to Seconds

The most immediate technical gain is the drastic reduction in processing time.

Where conventional furnaces require hours to ramp up, hold, and cool down, flash sintering completes the densification phase in just a few seconds. This represents a massive reduction in energy consumption and a fundamental shift in production throughput.

Solving the KNN Volatility Challenge

Suppressing Alkali Metal Volatilization

Potassium-Sodium Niobate (KNN) ceramics face a specific chemical challenge: volatile alkali metals (Potassium and Sodium) tend to evaporate during long exposure to high temperatures.

Traditional sintering, with its long holding times, often leads to compositional changes that degrade material performance. Flash sintering occurs so rapidly that alkali metal volatilization is effectively suppressed, preserving the stoichiometry of the ceramic.

Achieving Theoretical Density

Despite the incredibly short timeframe, the process achieves high densification.

The electric field facilitates rapid particle rearrangement and shrinkage. This allows the material to approach its theoretical density without the prolonged "soaking" periods that usually threaten the chemical stability of KNN.

Microstructural Optimization

Inhibiting Grain Coarsening

In traditional ceramics processing, high temperatures and long durations inevitably lead to grain growth (coarsening). Large grains can reduce mechanical strength and alter electrical properties.

The speed of flash sintering arrests this growth. It locks in a fine-grained structure because the grains simply do not have the time to coalesce and grow large.

Enhancing Piezoelectric Performance

The combination of high density, correct chemical composition (due to low volatilization), and fine grain size directly translates to performance.

Flash sintering results in KNN ceramics with superior piezoelectric properties. The method optimizes the microstructure specifically for the functional output required of these materials.

Understanding the Process Shift

The Move from Equilibrium to Kinetics

It is important to recognize that flash sintering moves the manufacturing process away from thermal equilibrium.

Traditional furnaces rely on slow, steady heat to ensure uniformity. Flash sintering relies on fast, kinetic responses to an electric field.

Operational Precision

Because the sintering event happens in seconds, the process window is much tighter than in traditional methods.

Success depends on the precise synchronization of the DC field application with the furnace temperature. Unlike a kiln that can be adjusted over minutes, flash sintering requires instantaneous control to manage the rapid energy release.

Making the Right Choice for Your Goal

This technology is not just about speed; it is about solving specific material constraints associated with KNN.

- If your primary focus is Compositional Purity: Flash sintering is the superior choice to prevent the loss of volatile elements (Potassium/Sodium) critical to KNN chemistry.

- If your primary focus is Microstructural Control: Choose this method to maintain ultrafine grain sizes that are impossible to achieve with long-duration thermal soaking.

- If your primary focus is Energy Efficiency: Flash sintering offers the highest potential for reducing operational costs by cutting cycle times from hours to seconds.

Summary: For KNN ceramics, flash sintering is not merely a faster alternative; it is a technical necessity for achieving peak piezoelectric performance by preventing chemical volatility and microstructural degradation.

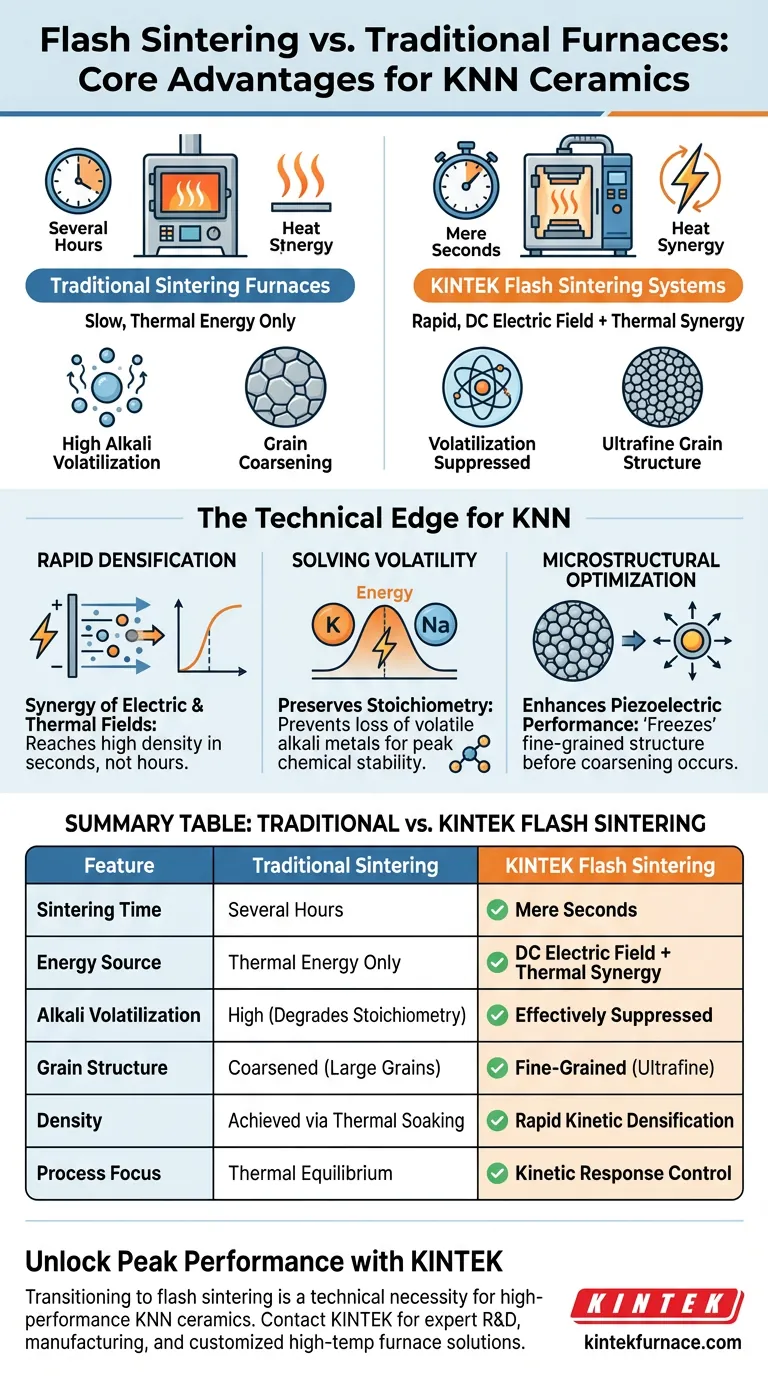

Summary Table:

| Feature | Traditional Sintering Furnaces | KINTEK Flash Sintering Systems |

|---|---|---|

| Sintering Time | Several Hours | Mere Seconds |

| Energy Source | Thermal Energy Only | DC Electric Field + Thermal Synergy |

| Alkali Volatilization | High (Degrades Stoichiometry) | Effectively Suppressed |

| Grain Structure | Coarsened (Large Grains) | Fine-Grained (Ultrafine) |

| Density | Achieved via Thermal Soaking | Rapid Kinetic Densification |

| Process Focus | Thermal Equilibrium | Kinetic Response Control |

Unlock Peak Piezoelectric Performance with KINTEK

Transitioning to flash sintering is a technical necessity for high-performance KNN ceramics. At KINTEK, we bridge the gap between material science and manufacturing efficiency. Backed by expert R&D and manufacturing, we provide high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temp furnaces fully customizable for your unique research and production needs.

Whether you are aiming to suppress alkali metal volatilization or achieve superior grain control, our team is ready to engineer your solution. Contact us today to optimize your sintering process!

Visual Guide

References

- Mingxiang Zhang, Fei Wang. Indium Doped Gan Porous Micro‐Rods Enhanced CO<sub>2</sub> Reduction Driving By Solar Light. DOI: 10.1002/admi.202301035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How do h-BN targets improve memristor switching ratios? Maximize Logic Windows with High-Purity Precursors

- What causes the increase in specific gravity of Moso Bamboo? Master Cellular Densification in Heat Treatment

- What role does the vacuum system play in regulating the length of ZnO branches? Master Precision in Nanostructures

- What is the mechanism of using TeCl4 as a gaseous transport agent? Grow High-Integrity Single Crystals with Ease

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- What are the requirements for sulfur powder loading in MoS2 synthesis? Master the 50-150 mg Precision Range

- Why must high-purity nitrogen be used for biochar activation? Ensure Carbon Integrity and Pore Development

- Why are DEZ and GEME selected for Ge:ZnO ALD? Unlock Precise Atomic Doping and Thermal Stability