To achieve high-quality molybdenum disulfide (MoS2) thin films, you must load between 50 and 150 mg of sulfur powder into the quartz tube. This specific mass range is required to generate the necessary sulfur vapor pressure to fully react with the molybdenum layer on your substrate during the heating process.

Precise control of sulfur loading is the primary determinant of film crystallinity. The mass of the powder directly dictates the partial pressure of sulfur vapor within the reaction chamber; staying within the 50–150 mg range ensures the reaction environment is sufficient to form high-quality MoS2 layers.

The Mechanics of Sulfurization

Sublimation and Transport

During the heating phase of synthesis, the solid sulfur powder does not melt but sublimates. This process converts the solid directly into sulfur vapor.

Creating the Reaction Atmosphere

This vapor serves as the active reactant source. It travels through the quartz tube to interact with the molybdenum precursor layer previously deposited on the substrate.

The Role of Partial Pressure

The specific quantity of powder loaded (50–150 mg) determines the concentration of sulfur vapor. This concentration creates the specific partial pressure required to drive the chemical conversion of Molybdenum to MoS2.

Impact on Film Quality

Determining Crystallinity

The primary reference indicates that the quantity of sulfur is a key factor in the structural order of the final material. Adequate vapor pressure allows the atoms to arrange themselves into a crystalline lattice structure.

Ensuring Film Integrity

If the sulfur concentration is optimized, the resulting film exhibits high quality. This generally refers to the uniformity of the layer and the minimization of atomic defects within the crystal structure.

Understanding the Trade-offs

The Consequence of Precision

Control is critical because the relationship between sulfur mass and film quality is direct. You cannot treat sulfur loading as a rough estimate; it is a calculated variable.

Risks of Deviation

While the 50–150 mg range is the standard, deviating from it disrupts the partial pressure balance. Too little sulfur (low pressure) likely results in incomplete sulfurization or poor crystallinity, while the specific effects of overloading would disrupt the optimal reaction equilibrium.

Optimization for Your Project

To determine the exact loading amount for your specific setup, consider these guidelines:

- If your primary focus is Maximum Crystallinity: Lean toward the upper end of the range (near 150 mg) to ensure the reaction chamber maintains high sulfur vapor partial pressure throughout the heating cycle.

- If your primary focus is Resource Efficiency: Begin at the lower threshold (50 mg) and assess the film quality; only increase the load if characterization reveals incomplete reaction or structural defects.

Precision in your precursor mass is the first step toward reproducibility in vapor-phase synthesis.

Summary Table:

| Parameter | Specification | Impact on Synthesis |

|---|---|---|

| Sulfur Mass Range | 50 – 150 mg | Determines sulfur vapor partial pressure |

| Physical Process | Sublimation | Converts solid powder directly to active reactant vapor |

| Lower Bound (50mg) | Minimum threshold | Prevents incomplete sulfurization or poor crystallinity |

| Upper Bound (150mg) | Maximum threshold | Ensures high partial pressure for peak crystallinity |

| Resulting Quality | High Integrity | Minimizes atomic defects and ensures uniform layering |

Elevate Your MoS2 Synthesis with KINTEK Precision

Achieving the perfect crystalline structure in 2D materials requires hardware that offers uncompromising thermal control. KINTEK provides industry-leading CVD systems, Tube furnaces, and Vacuum systems designed specifically for sensitive vapor-phase reactions.

Whether you are optimizing sulfurization protocols or scaling thin-film production, our customizable lab high-temp furnaces ensure the stable environment your research demands. Backed by expert R&D and manufacturing, we empower researchers to achieve high-integrity results every time.

Ready to optimize your thin-film quality? Contact KINTEK experts today to find the perfect system for your unique laboratory needs.

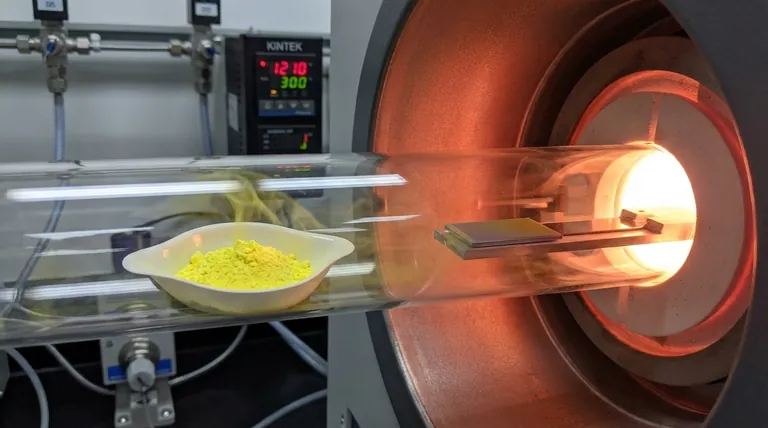

Visual Guide

References

- Saiful Islam, Nowshad Amin. Modulating Molybdenum Disulfide (MoS <sub>2</sub> ) Thin Films Formation via Vapor-Phase Synthesis: Time Variation. DOI: 10.1088/1755-1315/1560/1/012038

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- Why is a sample cell system with heating control necessary for the impedance analysis of yttrium-doped nickel ferrite?

- What role does the vacuum system play in regulating the length of ZnO branches? Master Precision in Nanostructures

- How does an annealing furnace work? A Guide to Controlled Heat Treatment

- What is the role of a laboratory vacuum drying oven in LNMO electrode slurry preparation? Master Solvent Removal

- What type of reaction environment is required for the synthesis of Ge-Se-Tl-Sb chalcogenide glasses? | KINTEK

- What role does starch play in g-C3N4-Bi2S3 and g-C3N4-ZnS synthesis? Enhance Composite Stability and Dispersion

- What technical advantages do high-temperature furnace systems provide for robust flexible interconnects? Enhance Durability

- What is the purpose of using a laboratory electric thermostatic blast drying oven in the pretreatment of sludge? Efficiency & Accuracy