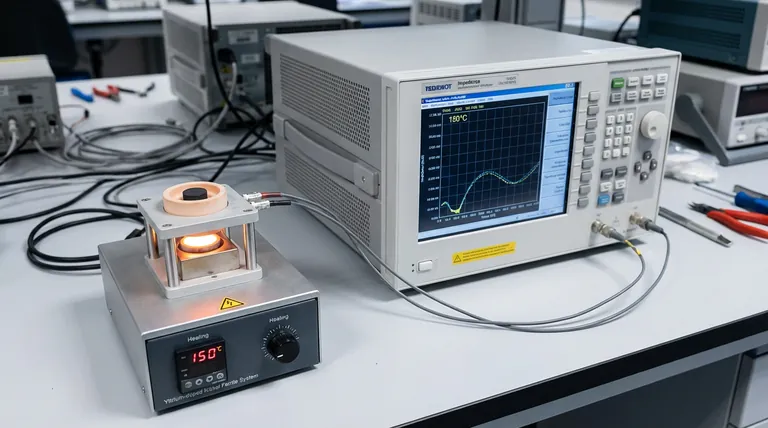

A sample cell system with heating control is essential for the impedance analysis of yttrium-doped nickel ferrite because the material’s electrical properties are inherently temperature-dependent. By maintaining a stable thermal environment, typically between 25°C and 200°C, researchers can induce and measure changes in conductivity that are invisible at room temperature.

The heating control system acts as a catalyst for characterizing the material's semiconducting nature. It enables the observation of thermally activated carrier hopping, providing the precise data points required to calculate activation energy using the Arrhenius law.

Unveiling Material Behavior Through Heat

The Necessity of Temperature Dependence

Yttrium-doped nickel ferrite does not behave statically; its electrical resistance changes as the temperature rises.

To characterize this material accurately, you cannot rely on a single room-temperature measurement. A heating control system allows you to sweep through a specific temperature range to map these dynamic changes.

Observing Carrier Hopping

The primary mechanism you are looking for is thermally activated carrier hopping.

Charge carriers in this ferrite require thermal energy to move (or "hop") between lattice sites. As the heating system increases the temperature, this hopping mechanism becomes more pronounced, allowing you to detect it through impedance spectroscopy.

Deriving Quantitative Data

Calculating Activation Energy

The ultimate analytical goal of using heating control is to determine the activation energy of the material.

This value represents the energy barrier that charge carriers must overcome to conduct electricity. Without a range of temperature-controlled data points, this calculation is impossible.

Applying the Arrhenius Law

The data collected across the 25°C to 200°C range is used to apply the Arrhenius law.

This mathematical principle correlates the rate of the chemical or physical reaction (in this case, conductivity) with temperature. Fitting your data to this law confirms the specific semiconducting characteristics of the nickel ferrite.

Understanding the Constraints

Thermal Equilibrium is Critical

A common pitfall in impedance analysis is measuring before the sample has fully stabilized at the target temperature.

The sample cell must hold the temperature constant long enough for the material to reach thermal equilibrium. If the temperature fluctuates during the frequency sweep, the impedance data will be distorted and unreliable.

Range Limitations

The system described operates within a specific window of 25°C to 200°C.

While this covers the relevant range for carrier hopping in this specific context, it is important to note that phase transitions or behaviors occurring at cryogenic temperatures or extreme heat (>200°C) will not be captured by this specific setup.

Making the Right Choice for Your Goal

To get the most out of your impedance analysis, align your approach with your specific objectives:

- If your primary focus is identifying semiconducting behavior: Use the heating system to generate an Arrhenius plot and verify if the data fits a linear relationship.

- If your primary focus is understanding conduction mechanisms: Analyze the changes in impedance at different thermal steps to observe the onset of carrier hopping.

Control over temperature transforms impedance analysis from a simple resistance check into a deep investigation of the material's energy landscape.

Summary Table:

| Feature | Importance in Impedance Analysis |

|---|---|

| Temperature Range | 25°C to 200°C for mapping dynamic conductivity changes |

| Carrier Hopping | Thermally activated movement of charges between lattice sites |

| Analytical Goal | Determination of Activation Energy via Arrhenius Law |

| Thermal Equilibrium | Ensures data stability and reliability during frequency sweeps |

| Material Insight | Reveals semiconducting behavior invisible at room temperature |

Elevate Your Material Research with KINTEK

Precision is paramount when analyzing the energy landscape of advanced ferrites. At KINTEK, we understand that stable thermal environments are the backbone of reliable impedance spectroscopy. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temperature furnaces—all fully customizable to your specific research needs.

Whether you are calculating activation energy or observing complex conduction mechanisms, our systems provide the thermal equilibrium required for high-accuracy data. Contact us today to find the perfect heating solution for your lab!

References

- Mirjana Šiljegović, Vladimir Tadić. Impedance and Dielectric Analysis of Nickel Ferrites: Revealing the Role of the Constant Phase Element and Yttrium Doping. DOI: 10.3390/electronics13081496

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What is the function of a high-pressure hydrothermal reactor in graphene aerogel synthesis? Key to 3D Carbon Frameworks

- Why is a temperature-controlled heating system required for firing silver electrodes? Ensure Precision Ohmic Contacts

- What is the function of a laboratory oven in forage palm and agave biomass processing? Optimize Stabilization Today

- Why is a two-stage sintering process used for porous LATP? Master Structural Integrity and Porosity

- What is the temperature range of a lab furnace? Find Your Perfect Match

- What is the primary function of a vacuum drying oven in anode-free battery preparation? Expert Lab Solutions

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- What are the advantages of using multi-stage laboratory sintering furnaces? Ensure Defect-Free Powder Metallurgy