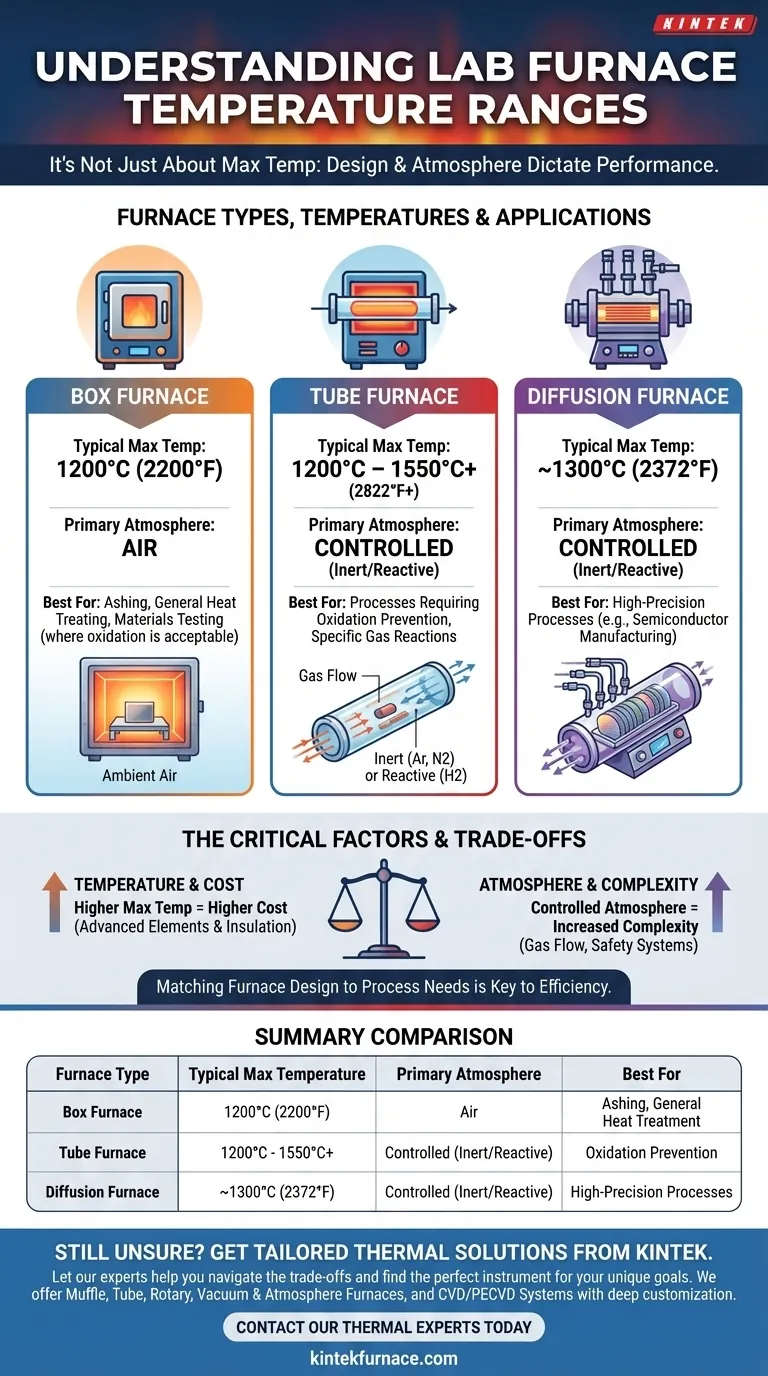

The temperature range for a standard laboratory furnace typically falls between 1200°C (2200°F) and 1550°C (2822°F). However, this range is not a universal specification. It is entirely dependent on the furnace's design, construction, and its intended application, particularly the type of atmospheric control it offers.

The critical takeaway is not the maximum temperature a furnace can reach, but understanding that different furnace types are engineered for specific temperature ranges and atmospheric conditions. Matching the furnace's design to your precise processing need is the most important consideration.

Why Furnace Type Dictates Temperature

The term "lab furnace" covers a range of instruments, each built for a different purpose. The maximum achievable temperature is a direct result of the materials used for its heating elements and insulation, which are chosen to suit specific tasks.

Box Furnaces for General Use

A box furnace is a common, general-purpose unit. These typically feature a front-opening door and a chamber for heating samples in ambient air.

Their typical maximum temperature is around 1200°C (2200°F). They are ideal for applications like ashing, heat treating, and materials testing where an air atmosphere is acceptable.

Tube Furnaces for Controlled Atmospheres

A tube furnace is designed for processes that require a controlled atmosphere. Samples are placed inside a tube (often ceramic or quartz) that runs through the heating chamber, allowing for the introduction of specific gases.

The temperature range for tube furnaces varies significantly based on their construction, from 1200°C for basic models up to 1550°C or higher for high-performance units.

Diffusion Furnaces for Specialized Processes

A diffusion furnace is a specialized type of tube furnace designed for high-precision applications like semiconductor manufacturing.

These furnaces, which can operate around 1300°C (2372°F), are built to handle a wide variety of gases, including inert gases like argon and reactive gases like hydrogen, to facilitate specific chemical processes.

The Critical Factor: Atmosphere Control

A furnace's temperature rating is intrinsically linked to the atmosphere it can safely contain. The ability to control the atmosphere is often more important than the maximum temperature itself.

Heating in Air

The simplest furnaces operate only in air. This is suitable for many applications but will cause oxidation on most metals and can interfere with certain chemical reactions. Box furnaces are almost always air-only instruments.

Inert and Reactive Atmospheres

For processes where oxidation or other reactions with air must be prevented, a furnace with an inert atmosphere package is necessary. This is a primary feature of tube furnaces.

These systems allow you to purge the air and fill the chamber with a non-reactive gas like argon or nitrogen. More advanced systems can also handle flammable or reactive gases like hydrogen, enabling processes like diffusion or annealing in a reducing environment.

Understanding the Trade-offs

Selecting a furnace involves balancing performance, capability, and cost. Higher specifications in one area often mean compromises in another.

Temperature vs. Cost

As a rule, the higher the maximum operating temperature, the more expensive the furnace. This is due to the need for more advanced heating elements (e.g., silicon carbide or molybdenum disilicide) and higher-grade insulation to safely and consistently maintain those temperatures.

Atmosphere Control vs. Simplicity

A simple box furnace that operates in air is far less complex and costly than a tube furnace equipped with gas flow controllers, sealed flanges, and safety systems for handling reactive gases like hydrogen.

Process Needs vs. Furnace Type

While a high-temperature tube furnace can perform the functions of a lower-temperature box furnace, it is often overkill. Using a complex instrument for a simple task increases operational complexity and cost without providing any additional benefit.

Making the Right Choice for Your Goal

To select the correct furnace, you must first define your process requirements. The right instrument is the one that meets your needs for temperature and atmosphere without adding unnecessary complexity or cost.

- If your primary focus is general heating or ashing in air: A standard Box Furnace operating up to 1200°C is the most direct and cost-effective solution.

- If your primary focus is processing materials without oxidation: A Tube Furnace with an inert atmosphere package is required, with models available from 1200°C to 1550°C depending on your material.

- If your primary focus involves specialized processes with reactive gases: You need a specialized Diffusion or Tube Furnace designed to handle gases like hydrogen, which typically operate in the 1300°C range.

Ultimately, defining your process requirements first is the key to selecting a furnace that serves as a reliable tool, not a limitation.

Summary Table:

| Furnace Type | Typical Max Temperature | Primary Atmosphere | Best For |

|---|---|---|---|

| Box Furnace | 1200°C (2200°F) | Air | Ashing, general heat treatment, materials testing |

| Tube Furnace | 1200°C - 1550°C+ | Controlled (Inert/Reactive) | Processes requiring oxidation prevention |

| Diffusion Furnace | ~1300°C (2372°F) | Controlled (Inert/Reactive) | High-precision processes like semiconductor manufacturing |

Still Unsure Which Furnace is Right for Your Process?

KINTEK provides more than just advanced high-temperature furnaces; we deliver tailored thermal solutions. Our expert team will help you navigate the critical trade-offs between temperature, atmosphere control, and cost to identify the perfect instrument for your specific experimental goals.

Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—complemented by strong deep customization capabilities to meet your unique requirements precisely.

Let's define your process needs together. Contact our thermal experts today for a personalized consultation and ensure your lab is equipped for success.

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance