At their core, tube furnaces create the pristine, high-temperature, and tightly controlled atmospheric conditions that are non-negotiable for fabricating modern electronics and energy storage devices. In semiconductor manufacturing, they are used for critical processes like annealing and chemical vapor deposition, while in battery production, they enable the synthesis and treatment of electrode materials through methods like sintering and graphitization.

The essential role of a tube furnace is not just to generate heat, but to create a miniature, isolated environment. This allows for the precise thermal processing of sensitive materials, protecting them from atmospheric contamination and ensuring the structural purity required for high-performance semiconductors and batteries.

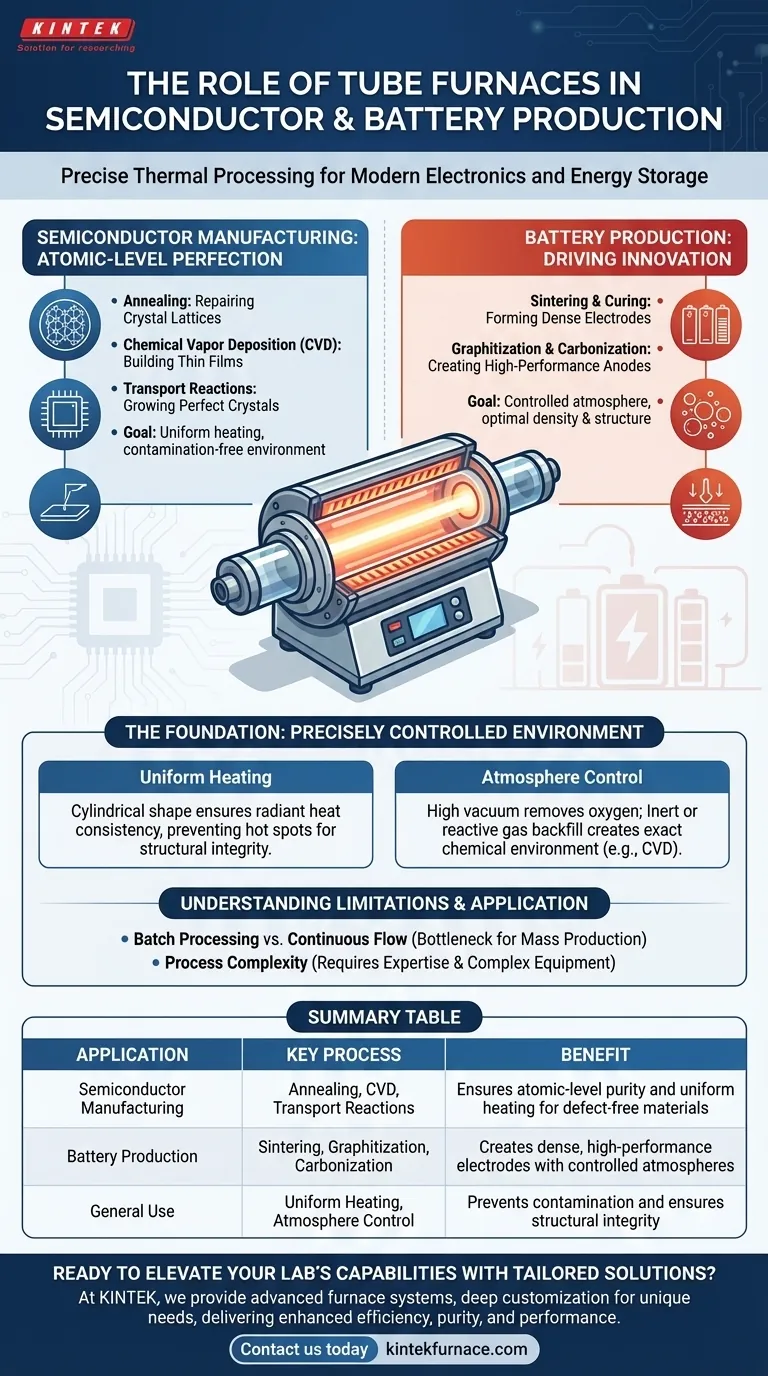

The Foundation: A Precisely Controlled Thermal Environment

The power of a tube furnace lies in its simple design: a cylindrical chamber, typically made of quartz or ceramic, that can be heated to extreme temperatures. This design is fundamental to its role in high-technology manufacturing.

Uniform Heating for Structural Integrity

The cylindrical shape of the tube ensures that the material placed inside receives exceptionally uniform radiant heat. This prevents hot spots and inconsistencies, which is critical for processes that depend on a perfect crystal structure or material density.

Precise temperature is maintained through sophisticated thermocouple feedback loops, ensuring process conditions are held stable to within fractions of a degree.

Atmosphere Control to Eliminate Impurities

The most crucial feature is the ability to control the atmosphere inside the tube. The chamber can be sealed and evacuated to a high vacuum, removing oxygen and other reactive gases that would otherwise contaminate and ruin the materials at high temperatures.

Following evacuation, the tube can be backfilled with a specific inert gas (like argon or nitrogen) or a reactive gas, creating the exact chemical environment needed for a specific process, such as chemical vapor deposition.

How Tube Furnaces Enable Semiconductor Manufacturing

The goal in semiconductor fabrication is atomic-level perfection. Tube furnaces provide the control needed to achieve this.

Annealing: Repairing Crystal Lattices

During processes like ion implantation, the crystal lattice of the silicon wafer is damaged. Annealing is a heat treatment process that allows the atoms to reorganize and repair this damage, restoring the wafer's electrical properties.

This requires uniform heating in a contamination-free environment to prevent the introduction of defects, a task for which tube furnaces are perfectly suited.

Chemical Vapor Deposition (CVD): Building Thin Films

CVD is a process where a reactive gas is introduced into the furnace, where it decomposes on the hot wafer surface to deposit a thin, solid film. These films form the insulating and conductive layers of a microchip.

The tube furnace's controlled atmosphere and precise temperature are essential for managing the chemical reaction and ensuring the deposited film has the desired thickness and purity.

Transport Reactions: Growing Perfect Crystals

For some advanced materials, tube furnaces are used for transport reactions, where a material is vaporized at one end of the tube and redeposited as a pure crystal at the cooler end. This process demands the stable temperature gradient that a tube furnace can provide.

How Tube Furnaces Drive Battery Innovation

In battery production, performance is dictated by the chemical composition and physical structure of the electrode materials. Tube furnaces are key tools for developing and refining these materials.

Sintering and Curing: Forming Dense Electrode Materials

Sintering is a process that uses heat to fuse particles together into a solid, dense mass without melting them. This is used to create the cathodes and anodes for lithium-ion batteries.

Running this process in a vacuum or inert gas tube furnace prevents oxidation and ensures the final electrode has the correct density and porosity, which directly impacts battery capacity and lifespan.

Graphitization and Carbonization: Creating High-Performance Anodes

High-performance anode materials, particularly synthetic graphite, are created through graphitization—a very high-temperature process that transforms carbon precursors into a highly structured graphite crystal.

This must be done in an oxygen-free environment to prevent the carbon from burning away, making the tube furnace an indispensable tool for this critical step in advanced anode production.

Understanding the Limitations and Trade-offs

While indispensable, tube furnaces are not a universal solution. Understanding their constraints is key to proper application.

Batch Processing vs. Continuous Flow

Traditional tube furnaces are inherently batch-processing tools. This is ideal for research, development, and high-value, lower-volume production where precision is paramount. However, it can be a bottleneck for mass production, which often favors continuous-flow systems.

Process Complexity

Achieving and maintaining a high-purity vacuum or a specific gas atmosphere requires complex supporting equipment like pumps, valves, and gas controllers. Operating these systems demands a high level of technical expertise to ensure process repeatability and safety.

Applying This to Your Goal

Your choice and use of a tube furnace should be guided by your end goal, as its strength lies in its precision control over the processing environment.

- If your primary focus is semiconductor purity: Prioritize a furnace system with high-vacuum capabilities and precise gas flow control to eliminate all sources of contamination during annealing and deposition.

- If your primary focus is battery material performance: Concentrate on achieving uniform temperature zones and a stable inert atmosphere to ensure complete sintering or graphitization for optimal material density and structure.

- If your primary focus is research and development: Select a versatile tube furnace that can accommodate a wide range of temperatures, atmospheres, and tube sizes to experiment with novel materials and processes.

Ultimately, mastering the controlled environment of a tube furnace is fundamental to manufacturing the materials that power our digital world and energy future.

Summary Table:

| Application | Key Process | Benefit |

|---|---|---|

| Semiconductor Manufacturing | Annealing, CVD, Transport Reactions | Ensures atomic-level purity and uniform heating for defect-free materials |

| Battery Production | Sintering, Graphitization, Carbonization | Creates dense, high-performance electrodes with controlled atmospheres |

| General Use | Uniform Heating, Atmosphere Control | Prevents contamination and ensures structural integrity in sensitive materials |

Ready to elevate your lab's capabilities with tailored high-temperature solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace systems like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise alignment with your unique experimental needs in semiconductor and battery production, delivering enhanced efficiency, purity, and performance.

Contact us today to discuss how our solutions can drive your innovations forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab