At their core, tube furnaces are used for a vast range of thermal processes where precise control over temperature and atmosphere is non-negotiable. Their applications span from fundamental materials science research—such as synthesizing novel materials like graphene or growing crystals—to critical industrial processes like heat-treating metals, producing battery components, and manufacturing semiconductors.

The defining advantage of a tube furnace is not just its ability to reach high temperatures, but its sealed, cylindrical chamber. This design provides unparalleled thermal uniformity and atmosphere control, making it indispensable for processes where material purity and structural integrity are paramount.

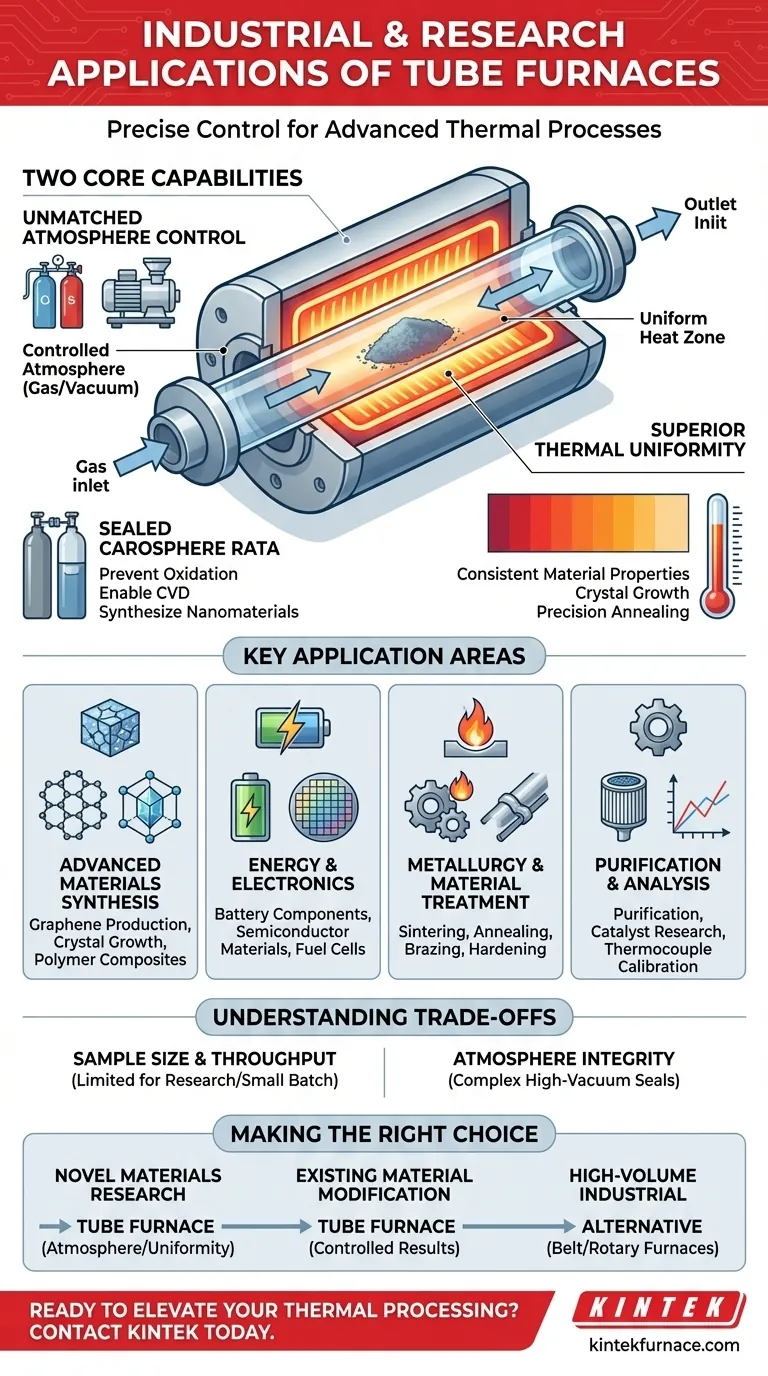

The Core Functions: Why Choose a Tube Furnace?

To understand its applications, you must first understand its two primary capabilities: superior atmosphere control and exceptional temperature uniformity. Nearly every use case is a direct result of one or both of these features.

Unmatched Atmosphere Control

The defining feature of a tube furnace is its process tube, which can be easily sealed and connected to gas or vacuum systems. This allows for precise management of the internal environment.

This control is critical for preventing oxidation or unwanted reactions with air. It also enables processes that require specific reactive gases or a complete vacuum.

Applications driven by this include Chemical Vapor Deposition (CVD), where gases react to form a solid film on a substrate, and the synthesis of sensitive nanomaterials.

Superior Thermal Uniformity

Heating elements are wrapped around the process tube, creating a radially uniform heat zone. This ensures that the entire sample experiences the same temperature profile.

This uniformity is essential for achieving consistent material properties. In processes like crystal growth or annealing, even minor temperature variations can ruin the final product.

Multi-zone tube furnaces take this further, allowing for the creation of precise temperature gradients along the length of the tube, which is useful for specialized synthesis and purification processes.

Versatility for Diverse Thermal Processes

Tube furnaces are workhorses for a wide array of fundamental thermal treatments used across both research and industry.

Key processes include:

- Sintering: Heating powdered materials below their melting point to form a solid, dense mass (e.g., ceramics).

- Annealing: Heating and slowly cooling a material (like metal or glass) to remove internal stresses and increase ductility.

- Calcination: Heating a material to a high temperature to cause thermal decomposition or remove volatile substances.

- Pyrolysis: Thermally decomposing organic materials in an oxygen-free environment.

Key Application Areas in Research and Industry

These core functions enable the use of tube furnaces in some of the most advanced and demanding fields of science and technology.

Advanced Materials Synthesis

Tube furnaces are at the forefront of materials science research and development. The ability to control the process environment is crucial for creating materials with novel properties.

Examples include the production of graphene, the synthesis of polymer composites, and the growth of single crystals for research and electronics.

Energy and Electronics

Many modern energy and electronics technologies rely on materials produced in highly controlled environments.

Tube furnaces are integral to developing solid oxide fuel cells (SOFCs), producing high-purity materials for semiconductors, and creating the electrode materials used in lithium-ion batteries.

Metallurgy and Material Treatment

In metallurgy, heat treatment is used to alter the physical and chemical properties of metals.

Tube furnaces are used for processes like hardening, tempering, and brazing (joining metals with a filler metal). They are also used for the heat treatment and testing of specialized aerospace alloys and ceramics.

Purification and Analysis

The sealed environment is perfect for processes that involve purification or testing under controlled conditions.

This includes the purification of inorganic and organic compounds through sublimation or degassing, catalyst research, and the precise calibration of thermocouples, which requires a stable and uniform temperature zone.

Understanding the Trade-offs

While incredibly versatile, tube furnaces are not the solution for every thermal processing need. Understanding their limitations is key to using them effectively.

Sample Size and Throughput

The diameter of the process tube inherently limits the size and volume of the sample. This makes tube furnaces ideal for research, testing, and small-batch production.

For high-volume, continuous industrial manufacturing, other solutions like belt or rotary furnaces are often more suitable.

Atmosphere Integrity Challenges

While capable of superior atmosphere control, achieving and maintaining a perfect seal for high-vacuum or ultra-high-purity gas environments can be challenging.

This requires careful selection of materials, proper flange assembly, and rigorous leak checking, adding a layer of operational complexity.

Making the Right Choice for Your Application

Your choice of thermal processing equipment must align with your primary objective.

- If your primary focus is developing novel materials or researching chemical reactions: A tube furnace's superior atmosphere control and thermal uniformity are indispensable.

- If your primary focus is modifying the properties of existing materials: A tube furnace offers the controlled environment needed for consistent results in processes like annealing, sintering, or hardening.

- If your primary focus is high-volume industrial production: Carefully evaluate if the batch size of a tube furnace meets your throughput needs, or if a continuous furnace system is more appropriate.

Ultimately, the tube furnace is the definitive tool when the integrity of the material and its processing environment cannot be compromised.

Summary Table:

| Application Area | Key Processes | Benefits |

|---|---|---|

| Advanced Materials Synthesis | Graphene production, crystal growth | Precise atmosphere control, thermal uniformity |

| Energy and Electronics | Battery component production, semiconductor manufacturing | High purity, consistent material properties |

| Metallurgy and Material Treatment | Annealing, sintering, brazing | Stress removal, improved ductility |

| Purification and Analysis | Catalyst research, thermocouple calibration | Controlled environment for accurate results |

Ready to elevate your thermal processing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in materials research, energy development, or industrial production, we can help you achieve superior results. Contact us today to discuss how our solutions can benefit your lab or facility!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control