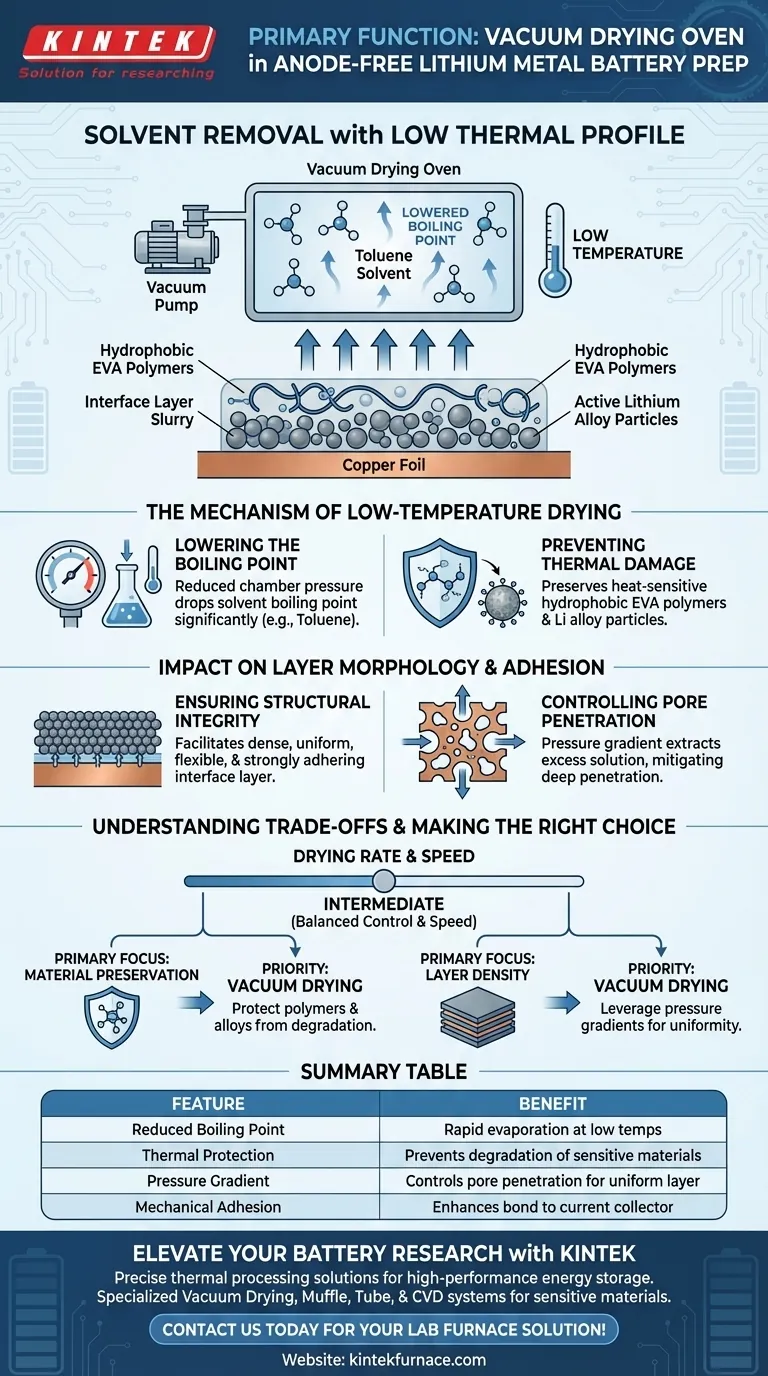

The primary function of a vacuum drying oven in this context is to remove solvents from the interface layer slurry coated on copper foil while maintaining a low thermal profile. By creating a vacuum environment, the oven significantly lowers the boiling point of solvents like toluene, allowing them to evaporate rapidly without requiring high temperatures. This prevents thermal degradation of sensitive components, such as hydrophobic EVA polymers and active lithium alloy particles.

The vacuum drying process solves the conflict between needing to dry a coating and needing to protect heat-sensitive materials. It utilizes reduced pressure to facilitate solvent removal at safe temperatures, ensuring the structural integrity of the interface layer.

The Mechanism of Low-Temperature Drying

Lowering the Boiling Point

The fundamental advantage of this method is the manipulation of atmospheric pressure. By reducing the pressure inside the chamber, the boiling point of the solvent (specifically toluene in this application) drops significantly.

Preventing Thermal Damage

This drop in boiling point allows the slurry to dry effectively without exposing the materials to excessive heat. This is critical for preserving the chemical structure of hydrophobic EVA polymers and lithium alloy particles, which could be compromised by standard high-temperature drying.

Impact on Layer Morphology and Adhesion

Ensuring Structural Integrity

Beyond simple evaporation, the vacuum process is essential for the mechanical properties of the final layer. It facilitates the formation of a dense, uniform, and flexible interface layer that adheres strongly to the copper foil current collector.

Controlling Pore Penetration

The vacuum environment creates a pressure gradient that influences how the solution interacts with the substrate. This gradient helps extract a portion of the solution that may have entered internal pores, mitigating deep penetration that could be detrimental to the cell's function.

Understanding the Trade-offs

Intermediate Drying Rates

While vacuum drying is effective for heat-sensitive materials, it is important to note its processing speed relative to other methods. The drying rate in a vacuum oven is typically lower than aggressive "quick drying" techniques, resulting in an intermediate thickness of the "egg-shell" layer.

Balancing Speed and Quality

You are essentially trading the raw speed of convective heating for control and material preservation. While not the fastest method available, it avoids the rapid skin formation that can trap solvents, while still being faster and more effective than a standard non-vacuum oven.

Making the Right Choice for Your Goal

To determine if vacuum drying is the correct approach for your specific battery interface fabrication, consider your primary constraints:

- If your primary focus is Material Preservation: Prioritize vacuum drying to protect heat-sensitive polymers like EVA and lithium alloys from thermal degradation.

- If your primary focus is Layer Density: Use this method to leverage pressure gradients for extracting excess solution from pores and ensuring a uniform, dense coating.

Success in anode-free battery preparation relies not just on removing the solvent, but on removing it in a way that engineers a stable, adhesive, and chemically active interface.

Summary Table:

| Feature | Benefit in Anode-Free Battery Prep |

|---|---|

| Reduced Boiling Point | Facilitates rapid evaporation of solvents like toluene at low temperatures. |

| Thermal Protection | Prevents degradation of hydrophobic EVA polymers and active lithium particles. |

| Pressure Gradient | Controls pore penetration for a dense, uniform, and flexible interface layer. |

| Mechanical Adhesion | Enhances the bond between the slurry and the copper foil current collector. |

Elevate Your Battery Research with KINTEK

Precise thermal processing is the backbone of high-performance energy storage. Backed by expert R&D and manufacturing, KINTEK offers specialized vacuum drying ovens, Muffle, Tube, and CVD systems designed to handle sensitive materials like EVA polymers and lithium alloys. Whether you need a standard setup or a customizable solution for unique anode-free battery architectures, we deliver the stability and control your lab requires.

Ready to optimize your interface layer performance? Contact us today to find your perfect lab furnace solution!

Visual Guide

References

- Cheng Lu, Yue Ma. A lightweight, Li supplementary and lithiophilic interface enables anode-less lithium metal battery prototyping. DOI: 10.1039/d5eb00042d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a water-cooled solid end? Master Thermal Gradients in Directional Solidification

- Why is a multiple high-temperature tempering process necessary for high-cobalt steels? Achieve Peak Hardness & Stability

- Why is precise heating rate control necessary? Master Activated Carbon Heat Treatment with KINTEK

- Why is an optical pyrometer necessary for monitoring nickel-aluminum alloy synthesis? Capture Rapid Thermal Explosions

- How does sodium metal function as a flux? Enhancing Sr-Ge-N Synthesis with Liquid-Phase Dynamics

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Why is precise temperature control in a drying oven critical for Li-SPAN battery cycle life? Ensure Peak Performance

- Why maintain argon and oxygen control in Titanium LMD? Ensure Peak Purity for Your High-Performance Components