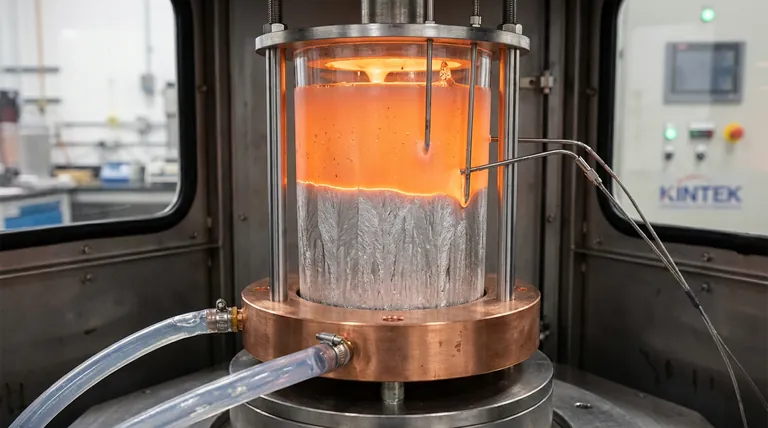

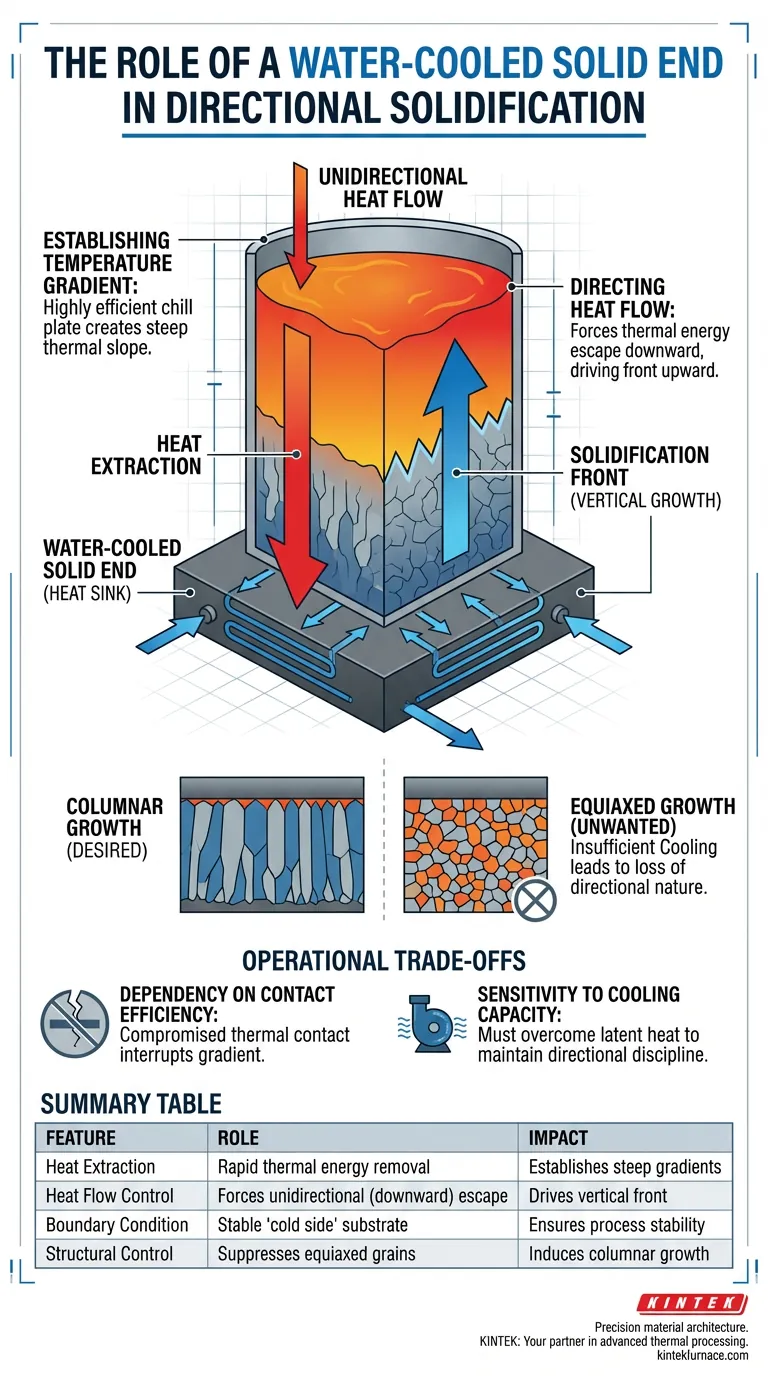

A water-cooled solid end serves as the critical heat-dissipating substrate in directional solidification systems. Its primary role is to extract heat rapidly from the bottom of the molten material, establishing a steep temperature gradient that forces the solidification front to move vertically from the base upward.

By defining the direction of heat flow, this component acts as the foundational boundary condition. It ensures that cooling occurs strictly from the bottom up, compelling crystals—particularly in aluminum alloys—to grow in a controlled, columnar structure rather than random equiaxed grains.

The Mechanics of Thermal Control

Establishing the Temperature Gradient

The fundamental requirement for directional solidification is a significant temperature difference between the solidifying interface and the melt.

The water-cooled solid end provides this by acting as a highly efficient chill plate. It creates a steep thermal slope, ensuring the bottom of the system remains significantly cooler than the molten alloy above it.

Directing Heat Flow

In solidification physics, crystal growth moves opposite to the direction of heat flow.

By aggressively cooling the base, the solid end forces thermal energy to escape downward. This unidirectional heat extraction is what physically drives the solidification front upward through the melt.

Impact on Material Structure

Inducing Columnar Growth

The geometry of the crystal structure is directly dictated by the heat flow established by this component.

As the solidification front advances upward, grains align with the thermal gradient. In materials like aluminum alloys, this results in a distinct columnar grain structure, which is often desirable for specific mechanical properties.

Defining Boundary Conditions

Consistency in material processing relies on predictable boundary conditions.

The water-cooled solid end establishes the fixed "cold side" boundary. This stability allows the process to maintain the necessary directional discipline required for high-quality casting.

Understanding the Operational Trade-offs

Dependency on Contact Efficiency

The effectiveness of the solid end is entirely dependent on its ability to act as a heat sink.

If the thermal contact between the melt and the solid end is compromised, heat extraction becomes non-uniform. This interrupts the steep temperature gradient, potentially causing the solidification front to stall or become uneven.

Sensitivity to Cooling Capacity

The system relies on the "steepness" of the gradient.

If the water cooling capacity is insufficient to overcome the latent heat of the melt, the directional nature of the process breaks down. This can lead to a transition from the desired columnar structure to a less predictable equiaxed structure.

Making the Right Choice for Your Goal

To effectively utilize a water-cooled solid end in your process, consider the following objectives:

- If your primary focus is Microstructural Alignment: Ensure the cooling capacity is sufficient to maintain a steep vertical gradient throughout the entire solidification time.

- If your primary focus is Process Repeatability: Monitor the interface between the solid end and the melt to guarantee consistent thermal boundary conditions for every cycle.

The water-cooled solid end is not just a cooling device; it is the steering mechanism that dictates the physical architecture of your final material.

Summary Table:

| Feature | Role in Directional Solidification | Impact on Material |

|---|---|---|

| Heat Extraction | Rapidly removes thermal energy from the base | Establishes steep temperature gradients |

| Heat Flow Control | Forces unidirectional (downward) heat escape | Drives solidification front vertically upward |

| Boundary Condition | Acts as the stable "cold side" substrate | Ensures process repeatability and stability |

| Structural Control | Suppresses random equiaxed grain formation | Induces high-quality columnar grain growth |

Precision material architecture starts with superior thermal control. At KINTEK, we understand that high-quality directional solidification requires stable and efficient cooling. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, including high-temp furnaces tailored for your unique research and industrial needs. Whether you are refining aluminum alloys or developing advanced composites, our team provides the technical expertise to optimize your thermal boundary conditions. Contact KINTEK today to elevate your laboratory's heat treatment capabilities with our high-performance furnace solutions.

Visual Guide

References

- G.‐J. Zhang, Shi Liu. Comparative study of gravity effects in directional solidification of Al-3.5 wt.% Si and Al-10 wt.% Cu alloys. DOI: 10.1038/s41526-024-00454-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

People Also Ask

- What role does a high-temperature sintering furnace play in lead-free piezoelectric ceramics? Optimizing Performance

- Why is a laboratory vacuum drying oven essential for the swelling-encapsulation-shrinkage method? Lock-in Film Quality

- What is the importance of the feeding system and ore distributing device? Unlock Peak Oil Shale Retorting Efficiency

- Why is the ball milling step essential for NN-10ST ceramic synthesis? Unlock High-Purity Phase Formation

- How does a precision drying oven influence ZnO gel drying? Achieve Perfect Microporous Structures

- What are the main types of laboratory furnaces based on size? Find the Perfect Fit for Your Lab's Scale

- What function does an electric blast drying oven serve in fluorite tailings activation? Ensure Process Precision

- What roles does a laboratory oven play in biochar production? Enhance Efficiency and Accuracy in Thermal Processing