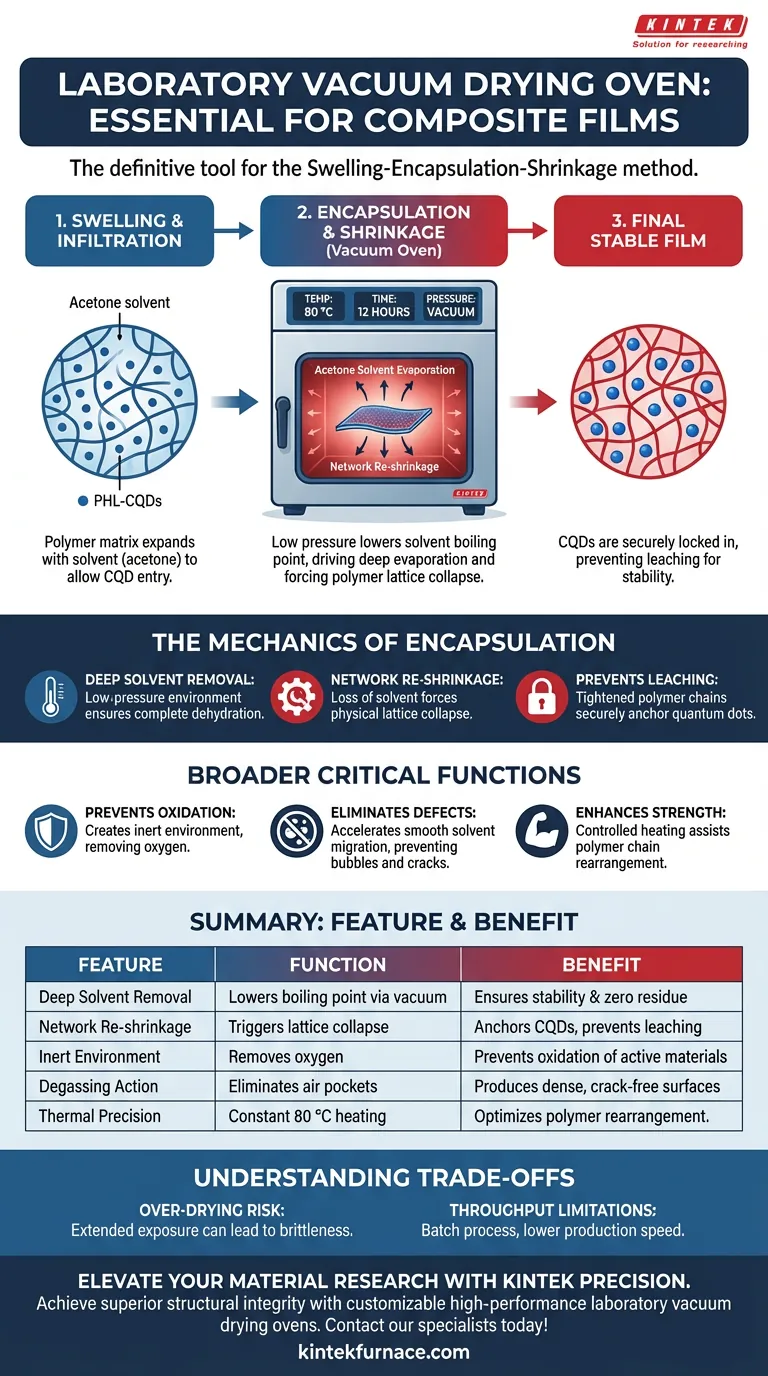

A laboratory vacuum drying oven is the definitive tool for ensuring the structural integrity and chemical stability of composite films prepared via the swelling-encapsulation-shrinkage method.

Specifically, it drives the critical final phase where the impregnated polyurethane film is baked at 80 °C under vacuum for 12 hours. This process forces the thorough removal of the acetone solvent, causing the swollen polymer network to re-shrink and securely anchor the embedded Phloroglucinol-based carbon quantum dots (PHL-CQDs), effectively preventing them from leaching out during future use.

Core Takeaway The vacuum drying oven acts as both a purification and a locking mechanism. By lowering the boiling point of solvents within the polymer matrix, it ensures complete dehydration without thermal damage, while simultaneously driving the physical lattice collapse necessary to permanently encapsulate guest molecules within the host film.

The Mechanics of Encapsulation and Shrinkage

The swelling-encapsulation-shrinkage method relies on a delicate balance of expanding a polymer's network to insert additives and then collapsing it to lock them in. The vacuum oven is the engine behind this collapse.

Facilitating Deep Solvent Removal

In this specific method, the polymer matrix is swollen with a solvent like acetone to allow the infiltration of quantum dots. The vacuum oven creates a low-pressure environment that lowers the boiling point of the acetone.

This allows the solvent to evaporate efficiently from deep within the polymer matrix. It ensures that no residual solvent remains to interfere with the material's final chemical properties.

Promoting Network Re-shrinkage

The removal of the solvent is not just about purification; it is the trigger for structural change. As the vacuum pressure extracts the acetone, the swollen polyurethane network loses its internal support.

This forces the network to undergo re-shrinkage, collapsing back to its original dense state. This physical contraction is what "traps" the PHL-CQDs inside the film.

Preventing Leaching Through Anchoring

Without the vacuum-induced shrinkage, the polymer pores would remain too open, leading to unstable composites. The oven ensures the polymer chains tighten around the quantum dots.

This creates a secure mechanical anchor. The result is a composite film where the active ingredients are locked in place, preventing leaching during practical applications.

Broader Critical Functions of Vacuum Drying

Beyond the specific mechanism of shrinkage, the vacuum environment provides essential benefits that standard atmospheric drying cannot match.

Eliminating Defects and Bubbles

Heating under atmospheric pressure often causes solvents to boil violently or air pockets to expand, creating surface cracks and internal bubbles.

Vacuum drying creates a negative pressure environment that accelerates the migration of residual water and trace solvents smoothly. This prevents pinholes and ensures the film remains dense, flat, and structurally sound.

Enhancing Mechanical Strength

The controlled heating environment of a vacuum oven assists in the orderly rearrangement of polymer chains. By removing internal stress during the late stages of film formation, the oven enhances the material's overall mechanical strength.

Preventing Oxidation

Standard ovens expose materials to hot air, which can degrade sensitive components. A vacuum oven removes air from the chamber, creating an inert environment.

This is critical for preventing the oxidation of active materials or fine powders. It ensures the chemical stability of the components is maintained throughout the drying process.

Understanding the Trade-offs

While essential for this method, vacuum drying introduces specific variables that must be managed to avoid compromising the sample.

Risk of "Over-Drying" or Brittleness

Extended exposure to heat and vacuum can sometimes extract too much moisture or plasticizer from a polymer, potentially leading to brittleness. It is vital to adhere to the specific protocol (e.g., 12 hours at 80 °C) to avoid degrading the polymer's flexibility.

Process Throughput Limitations

Vacuum drying is inherently a batch process. Unlike continuous conveyor ovens, the chamber must be sealed and depressurized for every cycle. This limits the speed of production but is a necessary sacrifice for the high fidelity required in laboratory composite preparation.

Making the Right Choice for Your Goal

The swelling-encapsulation-shrinkage method requires precision. Your specific drying parameters should align with your ultimate performance metrics.

- If your primary focus is Durability and Longevity: Prioritize the full 12-hour vacuum cycle to ensure maximum network shrinkage, which guarantees the quantum dots are anchored and will not leach over time.

- If your primary focus is Surface Morphology: Monitor the vacuum ramp-up speed carefully; applying vacuum too aggressively at the start can cause rapid solvent boil-off that disturbs the surface flatness before the film solidifies.

Ultimately, the vacuum drying oven is not just a drying tool; it is an active participant in manufacturing the microstructure of your composite film.

Summary Table:

| Feature | Function in Swelling-Encapsulation-Shrinkage | Benefit to Composite Film |

|---|---|---|

| Deep Solvent Removal | Lowers acetone boiling point via low-pressure | Ensures chemical stability and zero residue |

| Network Re-shrinkage | Triggers lattice collapse after solvent extraction | Securely anchors CQDs to prevent leaching |

| Inert Environment | Removes oxygen and atmospheric contaminants | Prevents oxidation of sensitive active materials |

| Degassing Action | Eliminates internal air pockets and bubbles | Produces dense, flat, and crack-free surfaces |

| Thermal Precision | Constant 80 °C heating for 12-hour cycles | Optimizes polymer chain rearrangement |

Elevate Your Material Research with KINTEK Precision

Don't let residual solvents or unstable encapsulation compromise your composite film performance. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory vacuum drying ovens alongside our Muffle, Tube, Rotary, and CVD systems—all customizable to meet your specific research protocols.

Ready to achieve superior structural integrity? Contact our specialists today to find the perfect high-temperature solution for your unique laboratory needs.

Visual Guide

References

- Zoran Marković, Biljana M. Todorović Marković. Phloroglucinol-Based Carbon Quantum Dots/Polyurethane Composite Films: How Structure of Carbon Quantum Dots Affects Antibacterial and Antibiofouling Efficiency of Composite Films. DOI: 10.3390/polym16121646

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is aluminum foil used during selenization and carbonization? Unlock Superior ZnSe Nanoparticle Synthesis

- What is the primary function of a vacuum drying oven in CIIR nanocomposite molding? Optimize Your Solvent Removal

- How is temperature regulated in laboratory furnaces? Master Precision Control for Reliable Results

- How does a resistance heating furnace contribute to Al/Cu bimetallic interface preparation? Expert Thermal Solutions

- How is a vacuum oven utilized during the drying process of NVP/C gel? Ensure High Purity & Structural Integrity

- Why is a constant temperature drying oven set to 60°C for 24 hours? Optimizing Sr4Al6O12SO4 Powder Quality

- What are the advantages of electric current-assisted TLP bonding? Maximize Efficiency for Inconel 718 Joining

- Why is encapsulation with hBN or graphene required during TMD annealing? Shielding Your 2D Materials