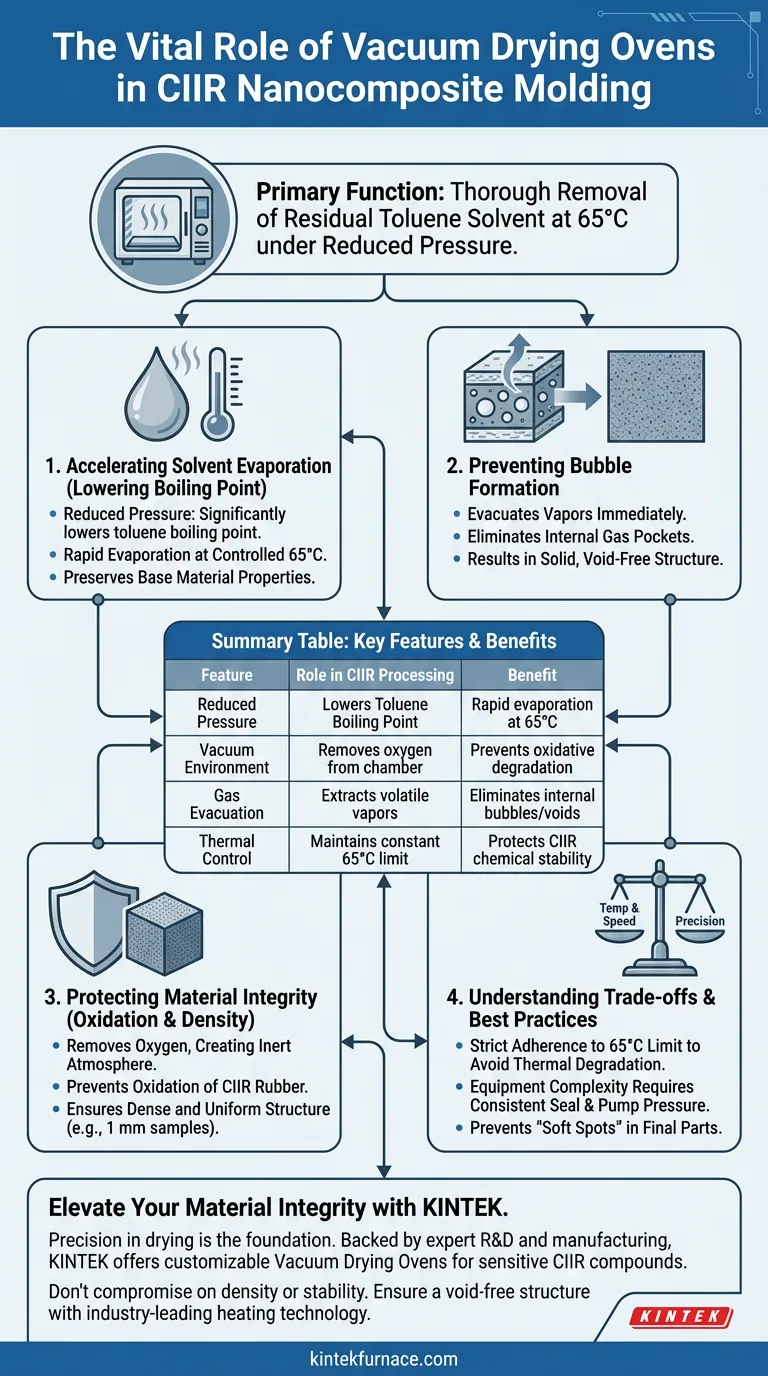

The primary function of a vacuum drying oven in the processing of Chlorobutyl Rubber (CIIR) nanocomposites is the thorough removal of residual toluene solvent. By maintaining a specific environment of 65 °C under reduced pressure, the oven accelerates solvent evaporation while simultaneously preventing the formation of bubbles and protecting the material from oxidation.

Vacuum drying is a critical quality control step that ensures structural density. It utilizes negative pressure to extract volatile solvents at moderate temperatures, preventing the voids and oxidative damage that occur with standard heating methods.

The Mechanics of Solvent Removal

Lowering the Boiling Point

The central advantage of this process is the ability to remove toluene without exposing the rubber to excessive heat.

By reducing the pressure inside the chamber, the boiling point of the solvent drops significantly.

This allows the solvent to evaporate rapidly and completely at a controlled temperature of 65 °C, preserving the base material's properties.

Preventing Bubble Formation

If solvent remains trapped within the rubber matrix as it cures or dries, it will eventually vaporize and expand.

Without the vacuum environment to draw these vapors out immediately, they form internal gas pockets or bubbles.

The vacuum drying oven ensures these vapors are evacuated, resulting in a solid, void-free structure.

Ensuring Material Integrity

Protection Against Oxidation

Standard drying ovens expose materials to heated air, which can accelerate degradation in sensitive compounds.

The vacuum environment removes oxygen from the chamber, creating an inert atmosphere during the drying phase.

This prevents oxidation of the Chlorobutyl Rubber, ensuring the chemical structure remains intact during the heating process.

Achieving Uniform Density

For the production of 1 mm thick nanocomposite samples, consistency is paramount.

Any residual solvent or trapped air creates weak points and density variations within the sample.

The vacuum process guarantees a dense and uniform structure, which is essential for accurate testing and performance of the final nanocomposite.

Understanding the Trade-offs

Temperature Precision vs. Speed

While higher temperatures might dry the material faster, they risk thermal degradation of the CIIR matrix.

You must adhere strictly to the 65 °C limit provided in the primary reference.

Rushing this process by increasing heat negates the protective benefits of the vacuum and compromises the nanocomposite.

Equipment Complexity

Vacuum drying adds a layer of complexity compared to simple convection drying.

It requires maintaining a consistent seal and pump pressure to be effective.

Inconsistent pressure levels can lead to incomplete solvent removal, leaving "soft spots" in the final molded part.

Making the Right Choice for Your Goal

To ensure the highest quality CIIR nanocomposites, apply the following principles:

- If your primary focus is structural density: Ensure the vacuum pressure is sufficient to fully evacuate evaporated toluene to prevent internal voids.

- If your primary focus is chemical stability: strictly monitor the temperature at 65 °C to avoid thermal degradation while relying on the vacuum for drying speed.

The success of your molding process relies on treating drying not just as a heating step, but as a precise purification technique.

Summary Table:

| Feature | Role in CIIR Nanocomposite Processing | Benefit |

|---|---|---|

| Reduced Pressure | Lowers the boiling point of Toluene | Rapid solvent evaporation at 65°C |

| Vacuum Environment | Removes oxygen from the chamber | Prevents oxidative degradation of rubber |

| Gas Evacuation | Extracts volatile vapors immediately | Eliminates internal bubbles and voids |

| Thermal Control | Maintains constant 65°C limit | Protects chemical stability of CIIR matrix |

Elevate Your Material Integrity with KINTEK

Precision in drying is the foundation of high-performance nanocomposites. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions, including specialized Vacuum Drying Ovens, Muffle, Tube, and CVD systems. Whether you are working with sensitive CIIR compounds or advanced ceramics, our equipment is fully customizable to meet your unique temperature and pressure requirements.

Don't compromise on density or stability. Ensure a void-free structure for your samples with our industry-leading heating technology. Contact our technical specialists today to find the perfect drying solution for your lab!

Visual Guide

References

- Tomy Muringayil Joseph, Sabu Thomas. Effects of Nanofillers and Synergistic Action of Carbon Black/Nanoclay Hybrid Fillers in Chlorobutyl Rubber. DOI: 10.3390/jcs8060209

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the function of controlled hot air flow treatment in ZnO drying? Master Surface Flatness and Stress Reduction

- What are the advantages of activated carbon in tantalum processing? Enhance Your Carburization Efficiency Today

- How does a rotating substrate holder contribute to the quality of CuGaO2 thin films? Achieve Uniformity in Sputtering

- What are the advantages of using KOH as a chemical activator? Enhance Biomass Carbon Surface Area and Porosity

- How do elliptical mirrors function to create a horizontal temperature field in an optical Floating-Zone furnace?

- How do Digital Twin and machine learning improve maintenance? Master High-Temp Equipment Reliability & Efficiency

- Why is the purity of oxide precursors critical for ZnO-doped CuO? Ensure High Photocatalytic Performance

- What is the primary function of a laboratory electric drying oven in ACBP production? Ensure Precise Pre-treatment