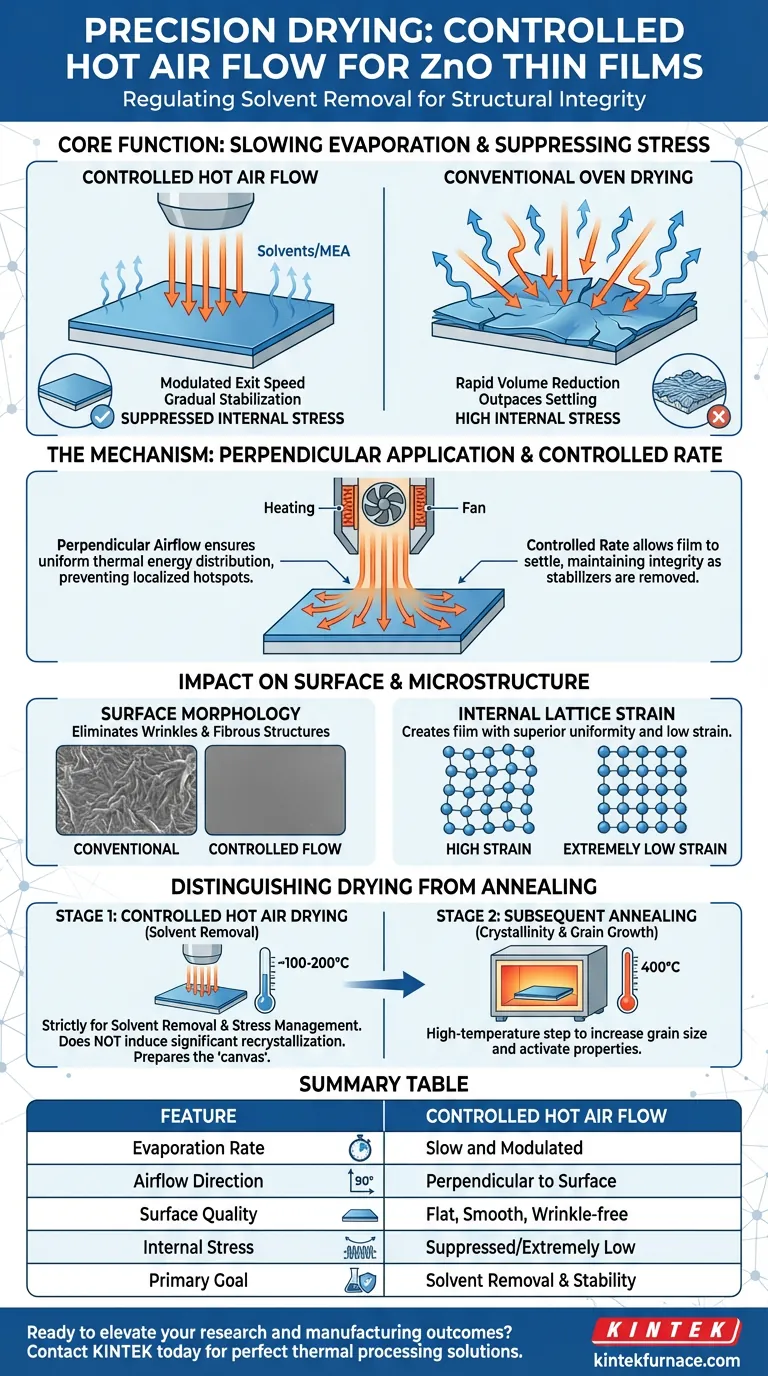

Controlled hot air flow treatment serves as a precision mechanism to regulate the rate of solvent removal during the drying phase of Zinc Oxide (ZnO) thin film production. By applying heat perpendicularly to the film surface, this process deliberately slows down the evaporation of solvents and stabilizers like monoethanolamine (MEA), preventing the structural damage often caused by rapid drying.

The core function of this treatment is to suppress internal stresses caused by shrinkage. By moderating the evaporation rate, it ensures a flatter, more uniform surface free from the wrinkles and fibrous structures associated with conventional oven drying.

The Mechanism of Stress Reduction

Controlled Evaporation Rate

The primary mechanism at work is the deceleration of evaporation. In standard drying, solvents leave the material quickly, leading to volume reduction that outpaces the material's ability to settle.

Controlled hot air flow modulates this exit speed. This allows the film to stabilize gradually, maintaining its structural integrity as the stabilizers (MEA) are removed.

Perpendicular Application

The directionality of the airflow is critical. Applying the hot air perpendicularly ensures that the thermal energy and airflow are distributed evenly across the film surface.

This prevents localized hotspots or uneven drying gradients that could induce warping or mechanical failure within the thin film layers.

Impact on Surface Morphology

Elimination of Surface Defects

Rapid shrinkage in conventional methods often results in physical deformities, specifically wrinkles and fibrous structures.

By slowing the drying process, controlled hot air flow eliminates these macroscopic defects. The result is a significantly smoother and flatter surface topology.

Minimizing Internal Lattice Strain

Beyond visible surface improvements, this treatment acts at a microscopic level. It creates a film with extremely low internal lattice strain.

Because the material is not forced to contract violently, the atomic lattice retains better uniformity, laying the groundwork for superior material properties.

Distinguishing Drying from Annealing

The Role of Temperature Limits

It is vital to distinguish this drying step from high-temperature annealing. The hot air treatment is strictly for solvent removal and stress management.

It does not induce significant recrystallization or grain growth.

The Role of Subsequent Annealing

While the hot air flow creates a flat, low-strain surface, it is the subsequent annealing at 400 °C (typically in a muffle furnace) that drives crystallinity.

As noted in broader processing contexts, that high-temperature step is required to increase grain size (e.g., from 7.5 nm to 15 nm) and activate photocatalytic properties. The hot air drying merely prepares the "canvas" for this later stage.

Making the Right Choice for Your Goal

To optimize your ZnO thin film production, you must view drying and annealing as complementary, not interchangeable.

- If your primary focus is Surface Flatness: Prioritize controlled hot air flow to prevent wrinkles and suppress the internal stress caused by rapid solvent evaporation.

- If your primary focus is Crystallinity and Grain Growth: You must follow the drying phase with high-temperature annealing (400 °C) to expand grain size and reduce boundary defects.

Summary: Controlled hot air flow is the critical preparatory step that ensures physical uniformity and low strain, enabling subsequent thermal processes to maximize the material's performance.

Summary Table:

| Feature | Controlled Hot Air Flow | Conventional Oven Drying |

|---|---|---|

| Evaporation Rate | Slow and Modulated | Rapid and Uncontrolled |

| Airflow Direction | Perpendicular to Surface | Ambient/Multidirectional |

| Surface Quality | Flat, Smooth, Wrinkle-free | Prone to Wrinkles and Fibers |

| Internal Stress | Suppressed/Extremely Low | High due to Rapid Shrinkage |

| Primary Goal | Solvent Removal & Stability | Basic Drying |

Precision Heat Treatment for Superior Thin Film Quality

Maximize the structural integrity of your ZnO thin films with heating solutions designed for precision. Whether you need controlled airflow systems to prevent surface defects or high-temperature furnaces for critical annealing steps, KINTEK provides the expertise you need.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or production requirements. Ensure low lattice strain and optimal grain growth in your materials with our advanced high-temperature lab furnaces.

Ready to elevate your research and manufacturing outcomes? Contact KINTEK today to find the perfect thermal processing solution for your needs.

Visual Guide

References

- Radka Gegova-Dzhurkova, I. Miloushev. Enhanced Photocatalytic Performance under Ultraviolet and Visible Light Illumination of ZnO Thin Films Prepared by Modified Sol-Gel Method. DOI: 10.3390/molecules29174005

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of a solvothermal reactor? Optimize Carbon Polymer Dots (CPDs) Synthesis with Precision Pressure

- What is the temperature of a sintering furnace? From 1100°C to 2200°C+ for Your Material

- What are the advantages of the Laser Hearth Method for Zirconia? Achieve High Purity & Density for Advanced Research

- What is the function of a sintering aid reservoir? Unlock Rapid Densification via MV-Sintering Technology

- How does high-temperature filtration equipment facilitate molten salt separation? Boost Your Slag Treatment Recovery

- What are the process advantages of using an electric melting furnace with an adjustable thermostat? Optimize Copper Scrap Refining

- What is the technical necessity of using a laboratory vacuum drying oven for Cu-Fe-N-C catalyst precursors?

- How does the introduction of SiO2 as an additive improve the sintering process of solid electrolytes? Boost Densification