The temperature of a sintering furnace is not a single value but a specific range determined by the material being processed. For common powder metallurgy involving iron, the temperature is typically around 1100-1150°C (2020-2100°F). However, for advanced ceramics or refractory metals, temperatures can be much higher, often exceeding 1600°C (2900°F) in specialized vacuum or controlled-atmosphere furnaces.

The central takeaway is that sintering temperature is dictated entirely by the material's properties and the desired final density. The furnace is simply the tool chosen to achieve and precisely control that required temperature, whether it's for steel, ceramics, or exotic alloys.

Why Temperature Is Not a Single Number

The question "What is the temperature of a sintering furnace?" is like asking "How fast does a vehicle go?" The answer depends entirely on the type of vehicle and its purpose. The same principle applies here, where the material dictates the thermal requirements.

The Critical Role of Material Properties

Sintering works by heating a compacted powder to a temperature high enough to cause atoms to diffuse across the boundaries of the particles, fusing them together.

This temperature is typically 70% to 90% of the material's absolute melting point. A lower-melting-point material like aluminum will sinter at a far lower temperature than a refractory metal like tungsten.

For example, sintering iron-based powders at ~1120°C is effective because it's well below iron's melting point (~1538°C) but high enough to activate atomic diffusion and bond the particles.

The Influence of the Sintering Process

The atmosphere inside the furnace is as critical as the temperature. Vacuum sintering or sintering in a controlled gas atmosphere (like nitrogen or argon) prevents oxidation and is essential for reactive materials or high-purity applications.

This environment can sometimes allow for different temperature profiles compared to sintering in open air, influencing the final properties of the component.

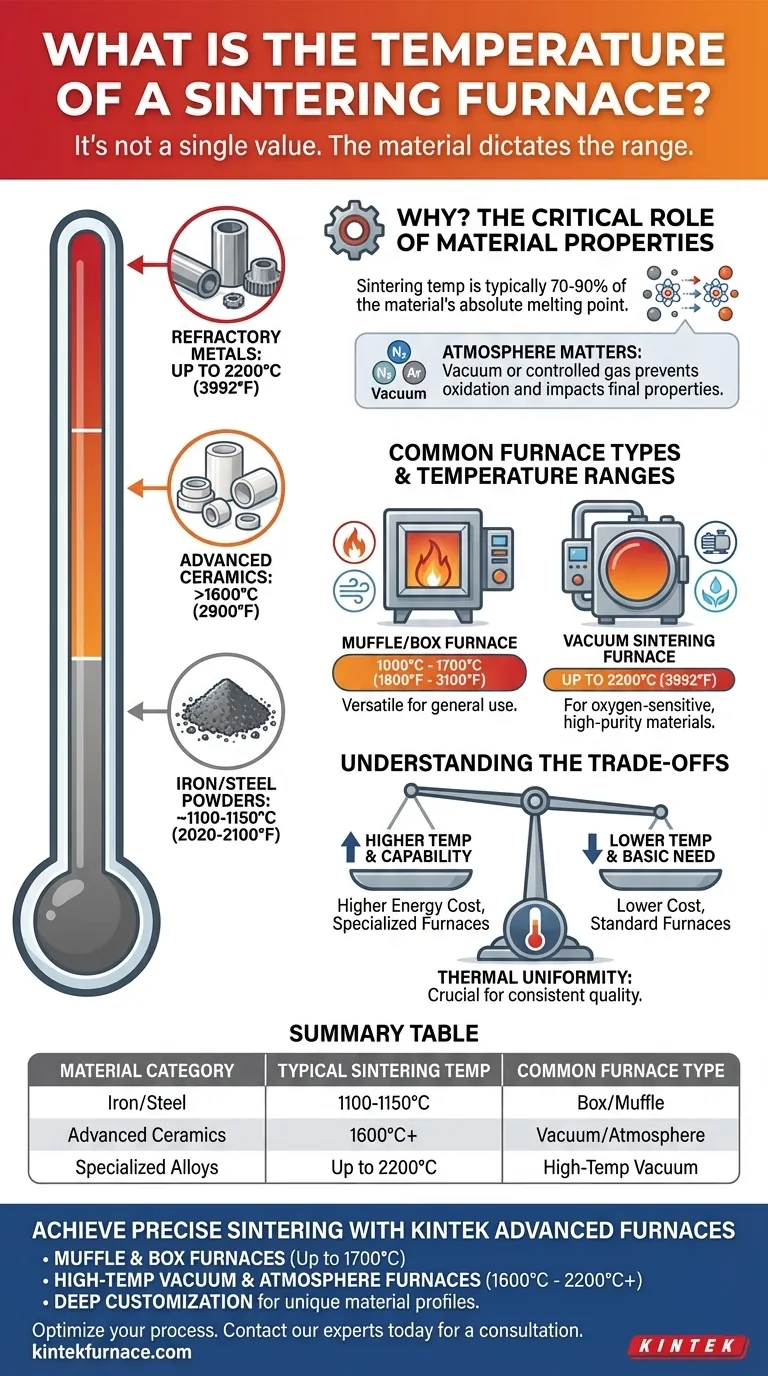

Common Furnace Types and Their Temperature Ranges

Different furnace designs exist to meet the varied temperature and atmospheric requirements of different materials.

Muffle and Box Furnaces

These are often used for general-purpose heat treatment and sintering. They provide good temperature control within a typical range of 1000°C to 1700°C (1800°F to 3100°F).

Their primary advantage is versatility for processing a wide range of materials in an air atmosphere.

Vacuum Sintering Furnaces

Designed for oxygen-sensitive materials and high-performance applications, vacuum furnaces create a clean environment to prevent contamination.

They can achieve very high temperatures, with many systems operating up to 1600°C (2912°F) and some specialized units reaching 2200°C (3992°F) or more.

Understanding the Trade-offs

Selecting a sintering temperature and furnace involves balancing performance, cost, and material science. It's a decision with clear engineering trade-offs.

Temperature vs. Energy Cost

Achieving and holding higher temperatures requires exponentially more energy. This directly translates to higher operational costs.

Running a furnace at 1600°C is significantly more expensive than running it at 1100°C. Therefore, using the lowest effective temperature for your material is key to process efficiency.

Furnace Capability vs. Material Needs

There is no "one-size-fits-all" furnace. A standard box furnace is perfectly adequate for many steel components but is completely unsuitable for sintering tungsten carbide, which requires much higher temperatures and a controlled atmosphere.

Over-specifying a furnace (e.g., buying a 2200°C vacuum furnace to sinter bronze) leads to unnecessary capital expense and operational complexity.

The Importance of Uniformity and Control

Reaching a peak temperature is not enough. The key to quality is thermal uniformity—ensuring every part of the component reaches and holds the exact same temperature.

Furnaces with advanced heating elements and insulation are designed for this precise control. A lack of uniformity can lead to inconsistent density, warping, or failed parts.

Making the Right Choice for Your Goal

To determine the correct temperature, you must first define your material and objective.

- If your primary focus is standard powder metallurgy (like iron or steel parts): Your target temperature will likely be in the 1100-1150°C (2020-2100°F) range.

- If your primary focus is advanced ceramics or refractory metals: You will need a high-temperature vacuum or controlled-atmosphere furnace capable of reaching 1600°C or higher.

- If your primary focus is process efficiency and quality control: Prioritize a furnace known for its temperature uniformity and precise control, not just its maximum temperature rating.

Ultimately, the right sintering temperature is the one that achieves your desired material properties with precision and efficiency.

Summary Table:

| Material Category | Typical Sintering Temperature Range | Common Furnace Type |

|---|---|---|

| Iron/Steel Powders | 1100°C - 1150°C (2020°F - 2100°F) | Box / Muffle Furnace |

| Advanced Ceramics / Refractory Metals | 1600°C+ (2900°F+) | Vacuum / Controlled-Atmosphere Furnace |

| Specialized Alloys | Up to 2200°C (3992°F) | High-Temp Vacuum Furnace |

Achieve Precise Sintering for Your Specific Material

Finding the exact temperature and furnace environment is critical for achieving the desired density and properties in your sintered components. Don't settle for a one-size-fits-all solution.

KINTEK's advanced high-temperature furnaces are engineered for this precision. Whether you are working with standard powder metallurgy or advanced ceramics, our solutions deliver the exact thermal control and uniformity you need.

- Muffle & Box Furnaces for robust processing up to 1700°C.

- High-Temp Vacuum & Atmosphere Furnaces for sensitive materials requiring 1600°C to 2200°C+ in a pure environment.

- Deep Customization to match your unique material profile and process requirements, leveraging our in-house R&D and manufacturing.

Let us help you optimize your sintering process. Contact our experts today for a consultation tailored to your material and goals.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is charcoal used as a susceptor in MHH for metal powders? Boost Microwave Efficiency with Hybrid Heating

- Why is a 1200°C hold required for Ti(C,N)-FeCr sintering? Unlock Superior Material Density

- Why is cordierite selected as the honeycomb support for HAN decomposition catalysts? Essential Design Insights

- Why is a forced-air drying oven necessary for impregnated kaolin catalysts? Achieve Uniform Component Immobilization

- How does programmed temperature control assist in Ti(C,N)-FeCr cermet degassing? Achieve Structural Integrity

- What physical characteristics of high-precision heating equipment are used in CSE selenium recycling?

- Why is precise temperature control necessary in high-temp furnaces for VN alloys? Master the Thermal Phase Switch

- What is the necessity of the subsequent pyrolysis step in ZnS-CFC preparation? Unlocking High-Performance Carbonization