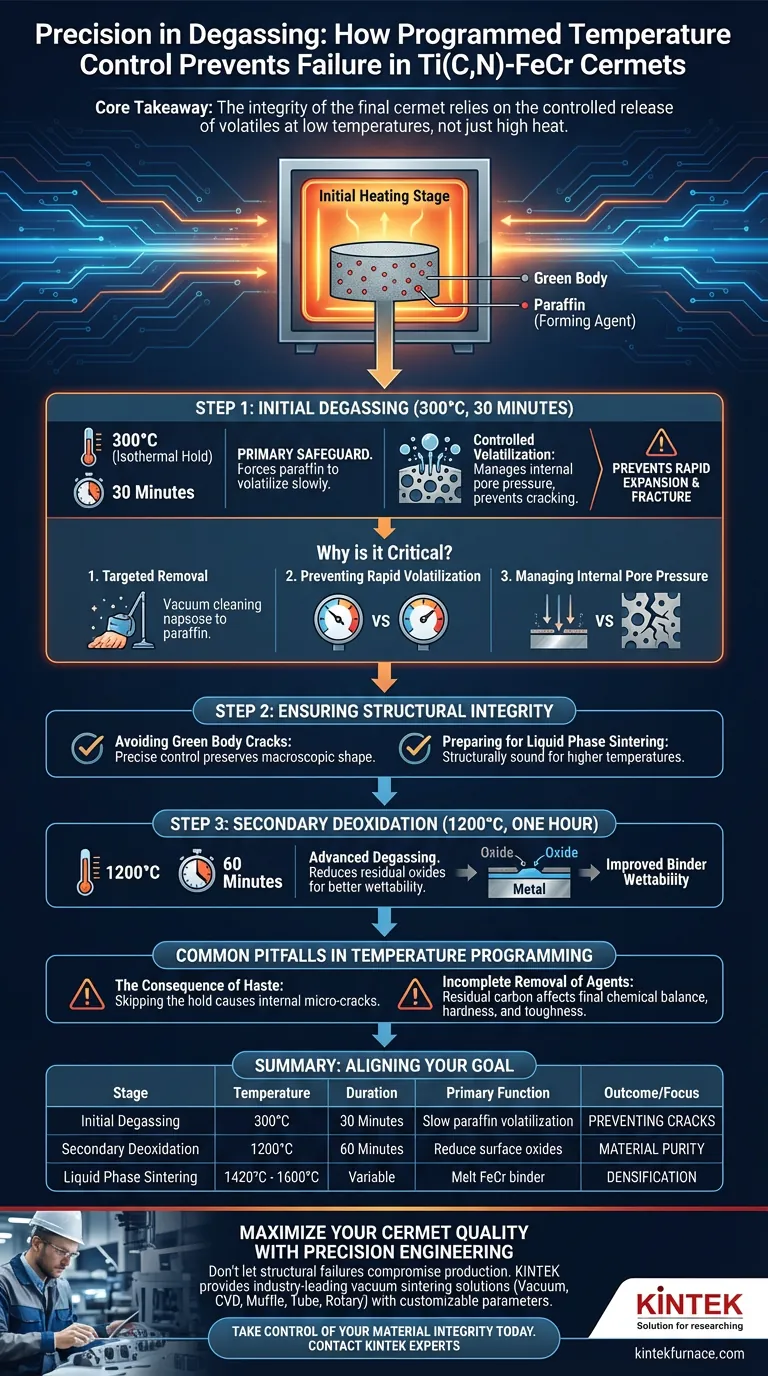

Programmed temperature control is the primary safeguard against catastrophic structural failure during the initial heating of Ti(C,N)-FeCr cermets. By strictly enforcing a 30-minute isothermal hold at 300°C, the furnace ensures that forming agents, specifically paraffin, are removed gradually. This precise regulation prevents the rapid expansion of gases that would otherwise fracture the fragile "green body" before high-temperature sintering begins.

Core Takeaway The integrity of the final cermet relies not just on high heat, but on the controlled release of volatiles at low temperatures. A dedicated isothermal hold allows forming agents to escape without generating the internal pressure that causes micro-cracking and component failure.

The Mechanism of Controlled Degassing

To understand why this stage is critical, one must look at the physical changes occurring within the compacted powder.

Targeted Removal of Forming Agents

During the pressing stage, agents like paraffin are added to bind the powder. These agents must be completely removed before the material enters the high-heat phases.

The vacuum sintering furnace is programmed to pause the heating ramp specifically at 300°C.

Preventing Rapid Volatilization

If the temperature rises too quickly, the paraffin transitions from solid to gas almost instantly. This rapid phase change creates a massive volume expansion within the material.

By holding the temperature steady for 30 minutes, the furnace forces the paraffin to volatilize at a manageable, slow rate.

Managing Internal Pore Pressure

The "green body" (the pressed but unsintered part) is porous but weak.

Controlled volatilization ensures the gas pressure inside these pores remains lower than the mechanical strength of the compact.

Ensuring Structural Integrity

The success of the subsequent sintering stages is entirely dependent on the quality of the part leaving the degassing stage.

Avoiding Green Body Cracks

The most immediate risk of improper degassing is cracking. If the gas exit rate exceeds the pore network's flow capacity, the stress will physically rip the material apart.

Precise temperature control eliminates this risk, preserving the macroscopic shape of the component.

Preparing for Liquid Phase Sintering

Once the forming agents are safely removed, the material is structurally sound enough to withstand higher temperatures.

This structural stability is a prerequisite for the later stages, where the furnace ramps up to 1500°C–1600°C to melt the FeCr binder and densify the cermet.

Secondary Deoxidation (Advanced Degassing)

While the primary degassing targets forming agents at 300°C, the temperature program plays a secondary purification role at higher temperatures.

Reducing Residual Oxides

Supplementary thermal control includes a one-hour isothermal hold at 1200°C.

This stage facilitates thermal chemical reactions that reduce oxygen impurities remaining on the powder surfaces.

Improving Binder Wettability

By removing these oxides in a vacuum, the process improves how well the metal binder wets the Ti(C,N) ceramic phase.

This ensures that when the liquid phase forms, it can fully penetrate and densify the material.

Common Pitfalls in Temperature Programming

Strict adherence to these thermal profiles is necessary because the trade-offs of speeding up the process are severe.

The Consequence of Haste

Skipping or shortening the 300°C hold to save time is a false economy.

Accelerating this stage almost guarantees internal micro-cracks, which may not be visible until the part fails under stress in its final application.

Incomplete Removal of Agents

If the hold time is insufficient, residual carbon from the paraffin may remain trapped.

This contamination can alter the chemical balance of the cermet, negatively impacting the hardness and toughness achieved during the final 1420°C to 1480°C sintering window.

Making the Right Choice for Your Goal

To maximize the performance of Ti(C,N)-FeCr cermets, your furnace programming must be aligned with specific processing milestones.

- If your primary focus is Preventing Cracks: Prioritize the 30-minute hold at 300°C to ensure the slow, safe release of paraffin forming agents.

- If your primary focus is Material Purity: Ensure your program includes a one-hour hold at 1200°C to reduce surface oxides and improve binder wettability.

- If your primary focus is Densification: verify the furnace can maintain precise control in the 1500°C to 1600°C range to facilitate uniform liquid phase sintering.

Success in cermet production is defined by the patience exercised during the initial heating stages, not just the intensity of the final heat.

Summary Table:

| Stage | Temperature | Duration | Primary Function |

|---|---|---|---|

| Initial Degassing | 300°C | 30 Minutes | Slow volatilization of paraffin to prevent green body cracking. |

| Secondary Deoxidation | 1200°C | 60 Minutes | Reduction of surface oxides to improve binder wettability. |

| Liquid Phase Sintering | 1420°C – 1600°C | Variable | Melting of FeCr binder for full densification and hardness. |

Maximize Your Cermet Quality with Precision Engineering

Don't let structural failures or impurities compromise your production. KINTEK provides industry-leading vacuum sintering solutions backed by expert R&D and world-class manufacturing. Whether you require Vacuum, CVD, Muffle, Tube, or Rotary systems, our high-temperature furnaces are fully customizable to meet your specific degassing and sintering parameters.

Take control of your material integrity today. Contact our technical experts at KINTEK to discover how our advanced furnace technology can optimize your lab or production workflow.

Visual Guide

References

- T.H. Pampori, Jakob Kübarsepp. Exploring Microstructural Properties, Phase Transformations, and Wettability in High-Chromium Content Iron-bonded Ti(C,N)-based Cermet. DOI: 10.2497/jjspm.16p-t14-06

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is the transformation of ZnS to ZnO critical in microwave-assisted zinc recovery? Unlock 92.5% Extraction Yields

- What is the significance of an in-situ high-temperature heating stage? Unlock Real-Time Crystal Structure Insights

- Why is a Cold Isostatic Press (CIP) utilized for LLTO samples? Achieve 98% Relative Density in Ceramics

- What is the role of a laboratory constant temperature drying oven? Preserving Magnetic Nanocatalyst Integrity

- How does a constant temperature forced air drying oven contribute to the pore activation process of biomass carbon?

- What role does phosphoric acid (H3PO4) play during the chemical activation stage of sawdust? Boost Porosity & Efficiency

- What is the necessity of preheating reinforcement materials? Eliminate Defects in Aluminum Alloys

- Why is an aging station required for Ni-doped LaFeO3 gas sensors? Ensure Stability and Precision