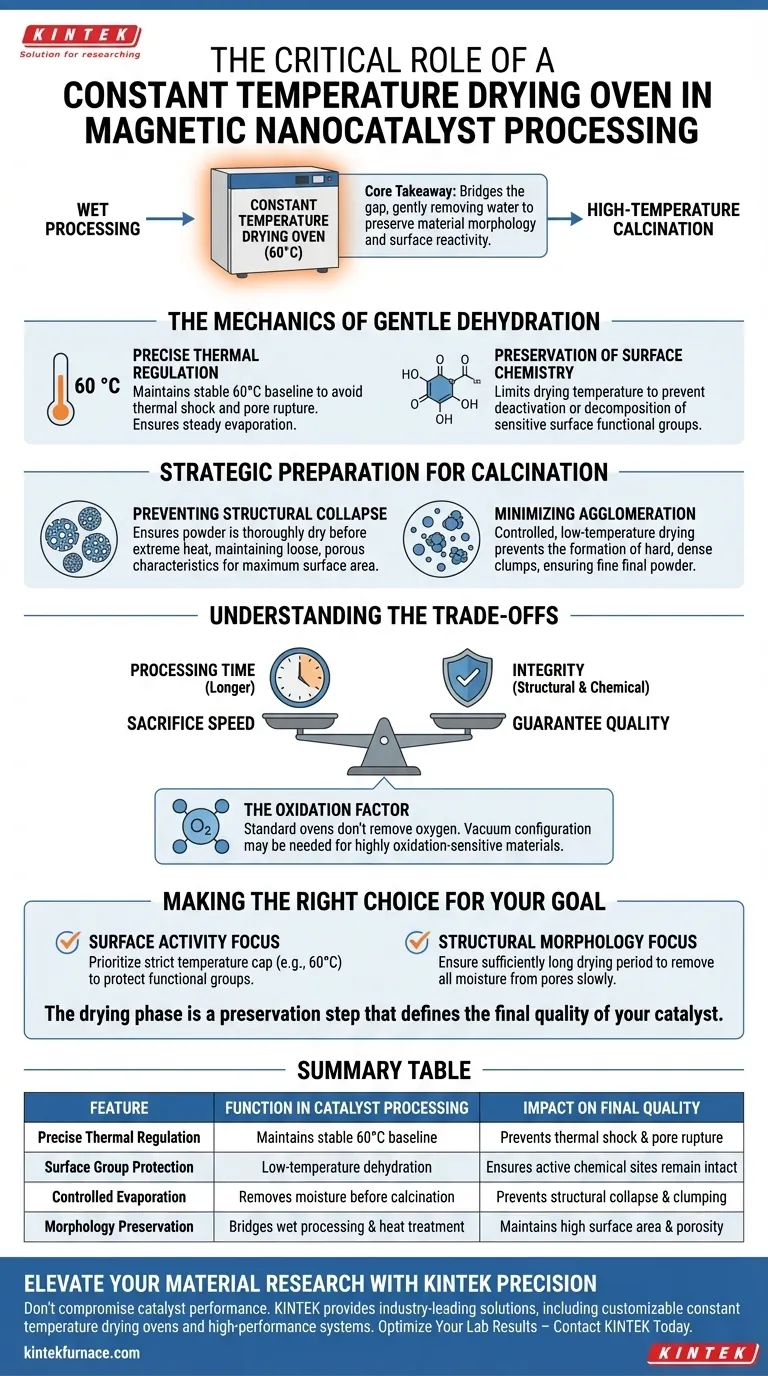

The laboratory constant temperature drying oven serves as a critical stabilization stage in the processing of magnetic nanocatalysts. It provides a controlled, low-temperature environment—typically maintained at 60 °C—to evaporate residual moisture from the material following the washing phase. Its primary value lies in dehydrating the powder without thermally degrading the delicate surface functional groups, thereby ensuring the material is chemically intact for subsequent high-temperature calcination.

Core Takeaway Direct exposure to high heat can destroy the active chemical sites and porous structure of a catalyst before it is fully finished. The constant temperature drying oven bridges the gap between wet processing and final calcination, gently removing water to preserve the material's morphology and surface reactivity.

The Mechanics of Gentle Dehydration

Precise Thermal Regulation

The drying process centers on maintaining a stable thermal baseline, often set at 60 °C for extended periods. This specific temperature threshold is aggressive enough to drive off water molecules trapped in the material but gentle enough to avoid thermal shock.

Unlike high-temperature furnaces used later in the process, the constant temperature oven ensures that the evaporation rate is steady. This prevents the rapid expansion of steam within the catalyst pores, which could otherwise rupture the material's internal structure.

Preservation of Surface Chemistry

The functional groups attached to the surface of magnetic nanocatalysts are often responsible for their chemical activity. These groups can be highly sensitive to heat.

By limiting the drying temperature, the oven prevents the deactivation or decomposition of these surface groups. This ensures that when the material eventually undergoes calcination or catalytic evaluation, the necessary chemical sites are present and active.

Strategic Preparation for Calcination

Preventing Structural Collapse

If a wet slurry is subjected immediately to high-temperature calcination, the physical stress of rapid drying can cause the material's morphology to collapse.

The constant temperature drying oven acts as a preparatory buffer. By ensuring the powder is thoroughly dry before it faces extreme heat, it helps maintain the loose, porous characteristics of the catalyst. This porosity is vital for maximizing the surface area available for catalytic reactions.

Minimizing Agglomeration

Wet nanoparticles have a tendency to clump together (agglomerate) if dried unevenly or too rapidly.

Controlled, low-temperature drying mitigates this risk. It helps maintain a fine micro-nano structure, preventing the formation of hard, dense clumps that are difficult to disperse later. This ensures the final powder remains fine and capable of optimal performance.

Understanding the Trade-offs

Time vs. Integrity

The primary trade-off of using a constant temperature drying oven is processing time. Because the temperature is kept low (e.g., 60 °C) to protect the material, the drying cycle is significantly longer compared to high-heat methods. You are sacrificing speed to guarantee structural and chemical integrity.

The Oxidation Factor

While a standard constant temperature oven controls heat, it does not inherently remove oxygen. For materials that are extremely sensitive to oxidation even at low temperatures, a standard oven may still allow for some oxidative degradation.

In cases where the nanocatalyst is highly prone to oxidation or requires the removal of stubborn solvents from deep pores, a vacuum configuration of the drying oven may be required to lower the pressure and exclude air, though the fundamental principle of controlled, low-temperature heating remains the same.

Making the Right Choice for Your Goal

To optimize the processing of your magnetic nanocatalysts, align your drying parameters with your specific material constraints:

- If your primary focus is Surface Activity: Prioritize a strict temperature cap (e.g., 60 °C) to ensure no functional groups are denatured during the drying phase.

- If your primary focus is Structural Morphology: Ensure the drying period is sufficiently long to remove all moisture from the pores slowly, preventing collapse or cracking during calcination.

The drying phase is not merely about water removal; it is a preservation step that defines the final quality of your catalyst.

Summary Table:

| Feature | Function in Catalyst Processing | Impact on Final Quality |

|---|---|---|

| Precise Thermal Regulation | Maintains stable 60°C baseline | Prevents thermal shock and pore rupture |

| Surface Group Protection | Low-temperature dehydration | Ensures active chemical sites remain intact |

| Controlled Evaporation | Removes moisture before calcination | Prevents structural collapse and clumping |

| Morphology Preservation | Bridges wet processing and heat treatment | Maintains high surface area and porosity |

Elevate Your Material Research with KINTEK Precision

Don't let improper drying compromise your catalyst's performance. KINTEK provides industry-leading laboratory solutions tailored for advanced material science. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as customizable constant temperature drying ovens designed to preserve your delicate nanocatalyst structures.

Whether you are scaling up production or refining surface chemistry, our team of experts is ready to help you find the perfect thermal processing equipment for your unique lab requirements.

Optimize Your Lab Results – Contact KINTEK Today

Visual Guide

References

- Biomass-Derived Magnetic Fe3O4/Biochar Nanoparticles from Baobab Seeds for Sustainable Wastewater Dye Remediation. DOI: 10.3390/ijms26178499

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a precision temperature-controlled furnace facilitate the long-term aging treatment of Invar 36?

- How does a precision carbon dioxide gas flow control system influence the precipitation of high-purity lithium carbonate?

- What are the core advantages of using a microwave hydrothermal synthesis system? Rapid & Uniform CNS Production

- How does a glove box provide environmental control for Mn2AlB2 precursors? Protect Material Purity & Reaction Accuracy

- What is the function of a drying oven in the post-treatment process of Ni and Zn-doped MgO nanoparticles?

- What are the advantages of the sol-gel nitrate combustion method? Achieve Atomic-Level Purity in Oxide Synthesis

- Why is a vacuum heating pretreatment system essential for zeolite characterization? Ensure Precise Pore Structure Data

- Why is precise temperature control essential for carbon material synthesis? Achieve Superior Purity and Microstructure