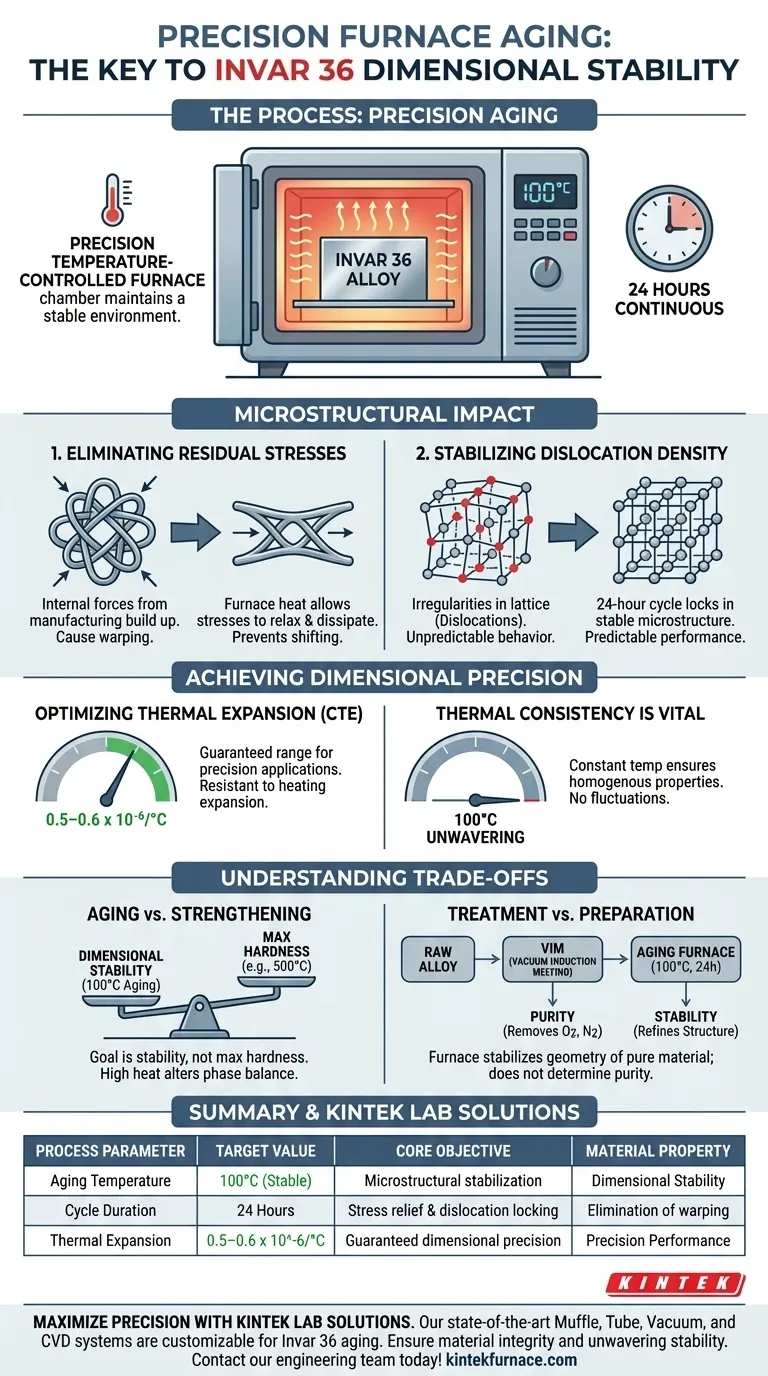

A precision temperature-controlled furnace facilitates the long-term aging of Invar 36 by maintaining a strictly stable environment at 100°C for a continuous 24-hour period. This specific thermal cycle is critical for eliminating residual internal stresses and stabilizing the alloy's microstructure without altering its fundamental composition.

The core objective of this process is to stabilize the dislocation density of the alloy, ensuring Invar 36 achieves its defining characteristic: an exceptionally low and consistent coefficient of thermal expansion (0.5–0.6 x 10^-6/°C).

The Microstructural Impact of Aging

Eliminating Residual Stresses

During the manufacturing and shaping of Invar 36, internal forces known as residual stresses build up within the material.

If left untreated, these stresses can cause the material to warp or shift over time. The furnace provides a controlled thermal environment that allows these internal forces to relax and dissipate.

Stabilizing Dislocation Density

Beyond simple stress relief, the 24-hour cycle at 100°C targets the alloy's crystalline structure.

The process stabilizes the dislocation density—irregularities in the crystal lattice. By "locking in" a stable microstructure, the furnace ensures the material behaves predictably under future thermal changes.

Achieving Dimensional Precision

Optimizing Thermal Expansion

The primary value of Invar 36 is its resistance to expanding when heated.

The precise aging treatment ensures the Coefficient of Thermal Expansion (CTE) remains within the target range of 0.5 to 0.6 x 10^-6/°C. Without this step, the CTE might fluctuate, compromising the alloy's precision applications.

The Role of Thermal Consistency

The "precision" aspect of the furnace is vital because fluctuations in temperature during the 24-hour cycle could introduce new inconsistencies.

A constant, unwavering 100°C ensures that the entire bulk of the material is treated uniformly, resulting in homogenous properties throughout the part.

Understanding the Trade-offs

Aging vs. Strengthening

It is important to distinguish the goal of this specific 100°C aging process from other heat treatments.

While precision furnaces can drive hardness and wear resistance through higher temperatures (e.g., 500°C for precipitation hardening in other alloys), the goal here is dimensional stability, not maximum hardness. Applying excessive heat could alter the phase balance detrimental to Invar's low expansion properties.

Treatment vs. Preparation

The aging furnace refines the structure of the solid metal, but it does not determine chemical purity.

Purity is established earlier in the process using Vacuum Induction Melting (VIM) to eliminate impurities like oxygen and nitrogen. The aging furnace acts as the finishing step to stabilize the physical geometry of that pure material.

Making the Right Choice for Your Goal

To achieve the best results with Invar 36, you must align your thermal processing with your specific engineering requirements.

- If your primary focus is Dimensional Stability: Utilize the precision furnace at 100°C for 24 hours to minimize CTE and residual stress.

- If your primary focus is Chemical Purity: Ensure the raw alloy was prepared using Vacuum Induction Melting (VIM) to prevent oxidation prior to any heat treatment.

Precision in thermal control is the bridge between a raw alloy and a high-performance engineering component.

Summary Table:

| Process Parameter | Target Value | Core Objective |

|---|---|---|

| Aging Temperature | 100°C (Stable) | Microstructural stabilization |

| Cycle Duration | 24 Hours | Stress relief & dislocation locking |

| Thermal Expansion (CTE) | 0.5–0.6 x 10^-6/°C | Guaranteed dimensional precision |

| Material Property | Dimensional Stability | Elimination of warping and shifting |

Maximize Dimensional Precision with KINTEK Lab Solutions

Don't let temperature fluctuations compromise your material integrity. KINTEK provides state-of-the-art Muffle, Tube, Vacuum, and CVD systems designed for the rigorous demands of Invar 36 aging and other precision heat treatments.

Backed by expert R&D and manufacturing, our high-temp furnaces are fully customizable to your unique thermal cycling needs, ensuring uniform heating and unwavering stability for your most critical components.

Ready to achieve superior material performance? Contact our engineering team today to discuss your custom furnace requirements!

Visual Guide

References

- Mehmet Kul, Markus Merkel. Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Invar 36. DOI: 10.3390/cryst14121097

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is precise temperature control in a drying oven critical for Li-SPAN battery cycle life? Ensure Peak Performance

- Why is the water quenching process necessary for high-entropy alloys? Master Phase Purity and Microstructural Integrity

- How does a vacuum pressure infiltration system contribute to Diamond/Cu composite green bodies? Achieve 60% Density

- How does the temperature field provided by a High-Temperature Reaction Furnace promote pore development? 700-800°C Mastery

- What is the function of solution and aging heat treatment furnaces? Optimize 17-4 PH Stainless Steel Properties

- What chemical role does phosphoric acid (H3PO4) play when activating biomass? Master Carbon Material Transformation

- What role does a nitrogen protection device play in copper-based halide thin films? Optimize Your Lab Annealing Process

- What is the technical purpose of the ball milling process for Ti12%Zr? Master Mechanical Activation & Alloying