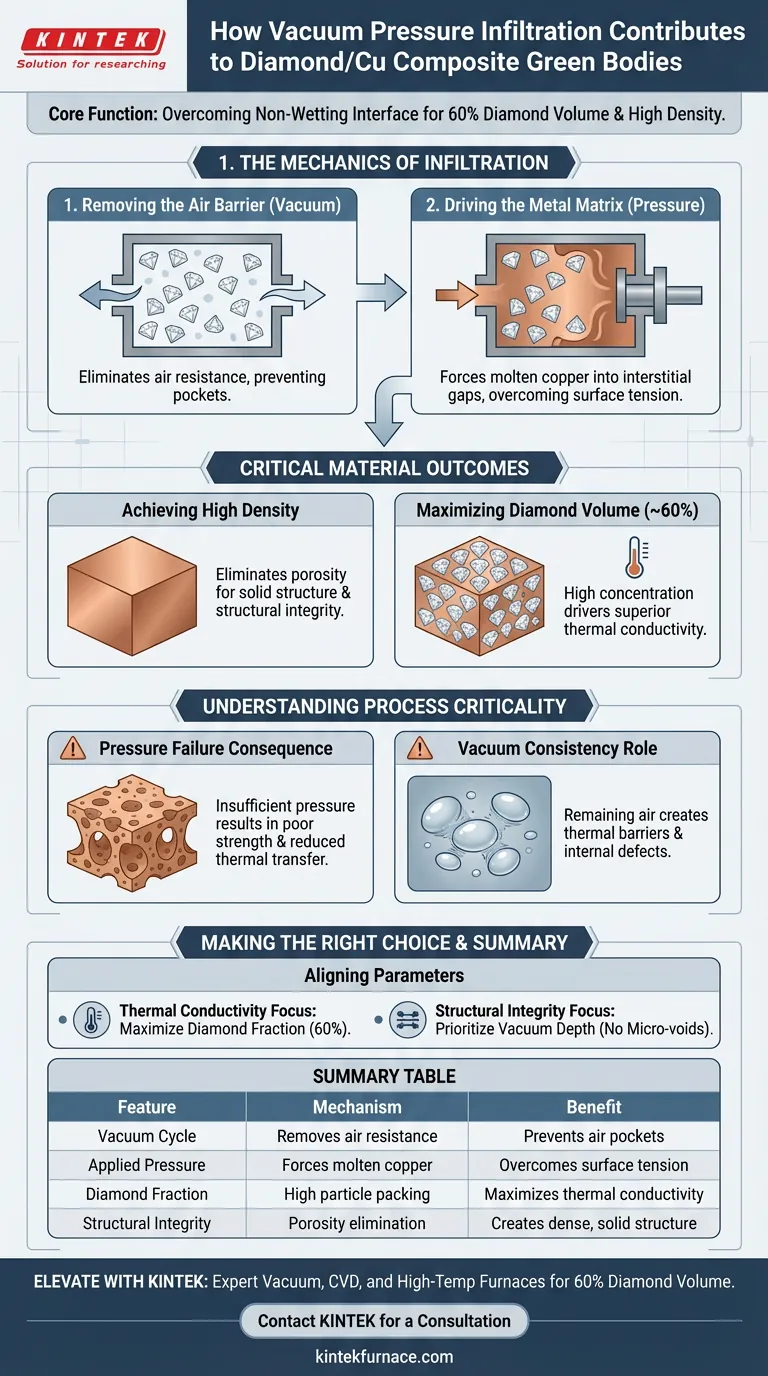

Vacuum pressure infiltration is the fundamental processing mechanism used to overcome the natural resistance between diamond particles and molten copper. This system operates by first creating a vacuum to eliminate air resistance within the pre-placed diamond particles, then applying external pressure to force liquid copper into the interstitial gaps.

The core function of this system is to mechanically overcome the non-wetting nature of the Diamond/Cu interface. By removing air barriers and driving infiltration with pressure, the system achieves a diamond volume fraction of approximately 60%, resulting in a dense composite with exceptional thermal conductivity.

The Mechanics of Infiltration

Removing the Air Barrier

The primary obstacle in creating a dense composite is the presence of air between particles. The vacuum component of the system exhausts residual air from the chamber before the metal is introduced.

By establishing a vacuum environment, the system prevents the formation of air pockets that would otherwise block the flow of molten copper.

Driving the Metal Matrix

Once the air is removed, the system applies significant external pressure. This pressure is strictly necessary to force the molten copper liquid into the tight spaces between the diamond particles.

Without this applied pressure, the surface tension of the copper would prevent it from fully penetrating the diamond preform.

Critical Material Outcomes

Achieving High Density

The combination of vacuum evacuation and pressurized infiltration ensures that the molten copper fully occupies the voids.

This process eliminates porosity, creating a solid, high-density composite structure that is free of the structural weaknesses caused by trapped gas bubbles.

Maximizing Diamond Volume

The efficiency of this system allows for a high concentration of diamond within the copper matrix.

According to standard processing metrics, this method facilitates a diamond volume fraction of approximately 60 percent. This high loading of diamond is the primary driver for the material's superior thermal properties.

Understanding the Process Criticality

The Consequence of Pressure Failure

If the external pressure is insufficient, the copper will bridge over the gaps between diamond particles rather than filling them. This results in a "sponge-like" structure with poor mechanical strength and reduced thermal transfer capabilities.

The Role of Vacuum Consistency

Pressure alone cannot compensate for a lack of vacuum. If air remains in the chamber, the applied pressure will simply compress the trapped gas bubbles rather than eliminating them. These compressed bubbles create internal defects that act as thermal barriers, defeating the purpose of using diamond.

Making the Right Choice for Your Goal

To maximize the effectiveness of a Diamond/Cu composite fabrication process, align your parameters with your specific performance targets:

- If your primary focus is Thermal Conductivity: Ensure the system pressure is tuned to maximize the diamond volume fraction to the target 60 percent, as the diamond carries the heat.

- If your primary focus is Structural Integrity: Prioritize the depth of the vacuum cycle to ensure absolute removal of air, preventing micro-voids that lead to cracking or delamination.

Ultimately, the vacuum pressure infiltration system is not just about shaping the material, but about forcing two dissimilar materials to act as a unified, high-performance thermal conductor.

Summary Table:

| Feature | Mechanism | Benefit |

|---|---|---|

| Vacuum Cycle | Removes air and gas resistance | Prevents air pockets and thermal barriers |

| Applied Pressure | Forces molten copper into gaps | Overcomes surface tension for full infiltration |

| Diamond Fraction | High particle packing (60%) | Maximizes thermal conductivity of the composite |

| Structural Integrity | Porosity elimination | Creates a dense, solid structure without defects |

Elevate Your Advanced Material Synthesis with KINTEK

Fabricating high-performance Diamond/Cu composites requires precision control over vacuum and pressure environments. KINTEK provides industry-leading thermal solutions, including customizable Vacuum, CVD, and High-Temp Furnaces, designed to meet the rigorous demands of your R&D or manufacturing processes.

Our expert-backed systems ensure you achieve the 60% diamond volume fraction and structural density your application requires. Whether you need standard lab equipment or a bespoke system for unique material challenges, our team is ready to support your goals.

Ready to optimize your infiltration process? Contact KINTEK today for a consultation!

Visual Guide

References

- Ying Zhou, Degan Xiong. An Investigation on the Spark Plasma Sintering Diffusion Bonding of Diamond/Cu Composites with a Cr Interlayer. DOI: 10.3390/ma17246026

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is hydrothermal synthesis utilized for the production of ZIF-8? Control Nanocrystal Purity and Uniformity

- What are the technical advantages of using high-purity hydrogen as a protective atmosphere? Boost Heat Treatment Speed

- How do high-power IR furnaces compare to traditional equipment for nanocomposites? Unlock Superior Material Control

- What role does thermal processing with precise temperature control and tensile stress play in PVDF fiber stabilization?

- How do laboratory thermostatic baths contribute to the phosphoric acid treatment of 3Y-TZP ceramics? Boost Bioactivity

- Why is precision temperature control critical for MnBi2Te4 growth? Ensure Success in Flux Method Crystallization

- What are the advantages of a laboratory vacuum drying oven for CT and CCT precursors? Preserve Nanostructural Integrity

- What is the significance of using a laboratory vacuum drying oven during the catalyst recovery phase of depolymerization?