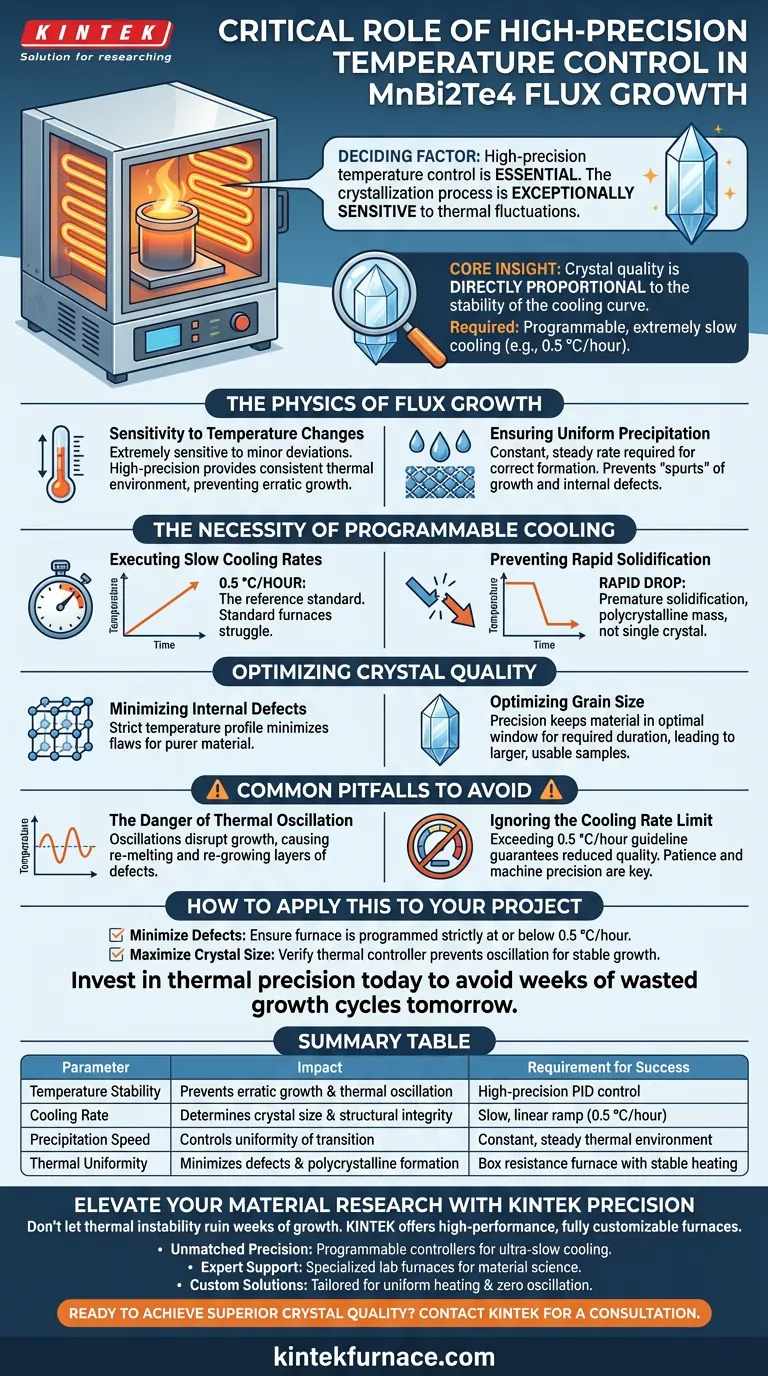

High-precision temperature control is the deciding factor in successfully growing MnBi2Te4 crystals because the material’s crystallization process is exceptionally sensitive to thermal fluctuations. To achieve high-quality growth via the flux method, the furnace must maintain a stable environment that allows the material to precipitate slowly and uniformly from the molten state.

Core Insight: The quality of MnBi2Te4 single crystals is directly proportional to the stability of the cooling curve. Without a furnace capable of executing extremely slow, programmable temperature drops (e.g., 0.5 °C/hour), the process will likely yield crystals plagued by internal defects and poor grain size.

The Physics of Flux Growth

Sensitivity to Temperature Changes

The crystallization of MnBi2Te4 is not a robust process that can withstand thermal instability. It is extremely sensitive to even minor deviations in temperature.

A high-precision box resistance furnace mitigates this by providing a consistent thermal environment. This stability prevents the erratic growth behaviors that occur when temperatures drift unexpectedly.

Ensuring Uniform Precipitation

For a single crystal to form correctly, it must precipitate from the molten flux at a constant, steady rate.

High-precision control ensures that the transition from liquid to solid happens uniformly. This prevents "spurts" of growth that can ruin the crystal's internal structure.

The Necessity of Programmable Cooling

Executing Slow Cooling Rates

The primary requirement for this material is the ability to execute specific, programmable cooling curves.

The reference standard for this process is a cooling rate of 0.5 °C per hour. This is an incredibly slow pace that standard, low-precision furnaces often struggle to maintain linearly.

Preventing Rapid Solidification

If the furnace cannot maintain this slow ramp and drops temperature too quickly, the flux will solidify prematurely.

Rapid solidification prevents the orderly arrangement of atoms required for single-crystal growth. Instead of a single large crystal, you may end up with a polycrystalline mass.

Optimizing Crystal Quality

Minimizing Internal Defects

Thermal control is the primary defense against structural flaws.

By maintaining a strict temperature profile, the furnace minimizes internal defects within the crystal lattice. This results in a purer material with better physical properties.

Optimizing Grain Size

The size of the final crystal—its grain size—is heavily dependent on how long it stays in the optimal growth window.

Precision control keeps the material in this window for the exact duration required. This optimizes the resulting grain size, leading to larger, more usable samples.

Common Pitfalls to Avoid

The Danger of Thermal Oscillation

A furnace may appear to hit a target temperature on average, but if it oscillates (swings up and down) around that setpoint, it will disrupt growth.

For MnBi2Te4, these oscillations can cause the crystal to partially re-melt and re-grow repeatedly. This creates layers of defects that ruin the sample.

Ignoring the Cooling Rate Limit

Attempting to accelerate the process by exceeding the 0.5 °C/hour guideline is a common error.

While faster cooling saves time, it almost strictly guarantees a reduction in crystal quality. The flux method requires patience and machine precision to work effectively.

How to Apply This to Your Project

To maximize your success with MnBi2Te4 growth, match your furnace settings to your specific quality goals:

- If your primary focus is minimizing defects: Ensure your furnace is programmed for a cooling rate strictly at or below 0.5 °C/hour to prevent internal flaws.

- If your primary focus is maximizing crystal size: Verify that your furnace's thermal controller prevents oscillation, as stability is required to grow large, singular grains.

Invest in thermal precision today to avoid weeks of wasted growth cycles tomorrow.

Summary Table:

| Parameter | Impact on MnBi2Te4 Growth | Requirement for Success |

|---|---|---|

| Temperature Stability | Prevents erratic growth & thermal oscillation | High-precision PID control |

| Cooling Rate | Determines crystal size and structural integrity | Slow, linear ramp (0.5 °C/hour) |

| Precipitation Speed | Controls uniformity of the liquid-to-solid transition | Constant, steady thermal environment |

| Thermal Uniformity | Minimizes internal defects and polycrystalline formation | Box resistance furnace with stable heating |

Elevate Your Material Research with KINTEK Precision

Don't let thermal instability ruin weeks of growth cycles. At KINTEK, we understand that growing complex crystals like MnBi2Te4 requires absolute control. Backed by expert R&D and world-class manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research needs.

Our value to you:

- Unmatched Precision: programmable controllers capable of the ultra-slow cooling rates essential for flux growth.

- Expert Support: Specialized lab furnaces designed for material science and semiconductor research.

- Custom Solutions: Tailored configurations to ensure uniform heating and zero oscillation.

Ready to achieve superior crystal quality? Contact KINTEK today for a consultation!

Visual Guide

References

- Yaoxin Li, Chang Liu. Fabrication-induced even-odd discrepancy of magnetotransport in few-layer MnBi2Te4. DOI: 10.1038/s41467-024-47779-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the two key phenomena essential to understanding induction heating? Master the Core Principles

- Why is 800 °C Required for Ln-MoP@C Phosphorization? Unlock Superior Catalyst Engineering

- What industries commonly use batch furnaces? Essential for Aerospace, Medical, and Electronics

- Why use automatic temperature compensation for Sb-Te melts? Ensure Data Accuracy with Precise Thermal Control

- What is the temperature of a graphite furnace? Unlock Extreme Heat Up to 3000°C

- What is the purpose of using high-purity argon gas for NAB alloys? Ensure Superior Nickel-Aluminum Bronze Integrity

- What is the purpose of the 0.5 cm tunnel structure in LLZO sintering? Achieve Superior Structural Uniformity

- What is the function of industrial furnaces in 7075 aluminum solution treatment? Master Material Strength