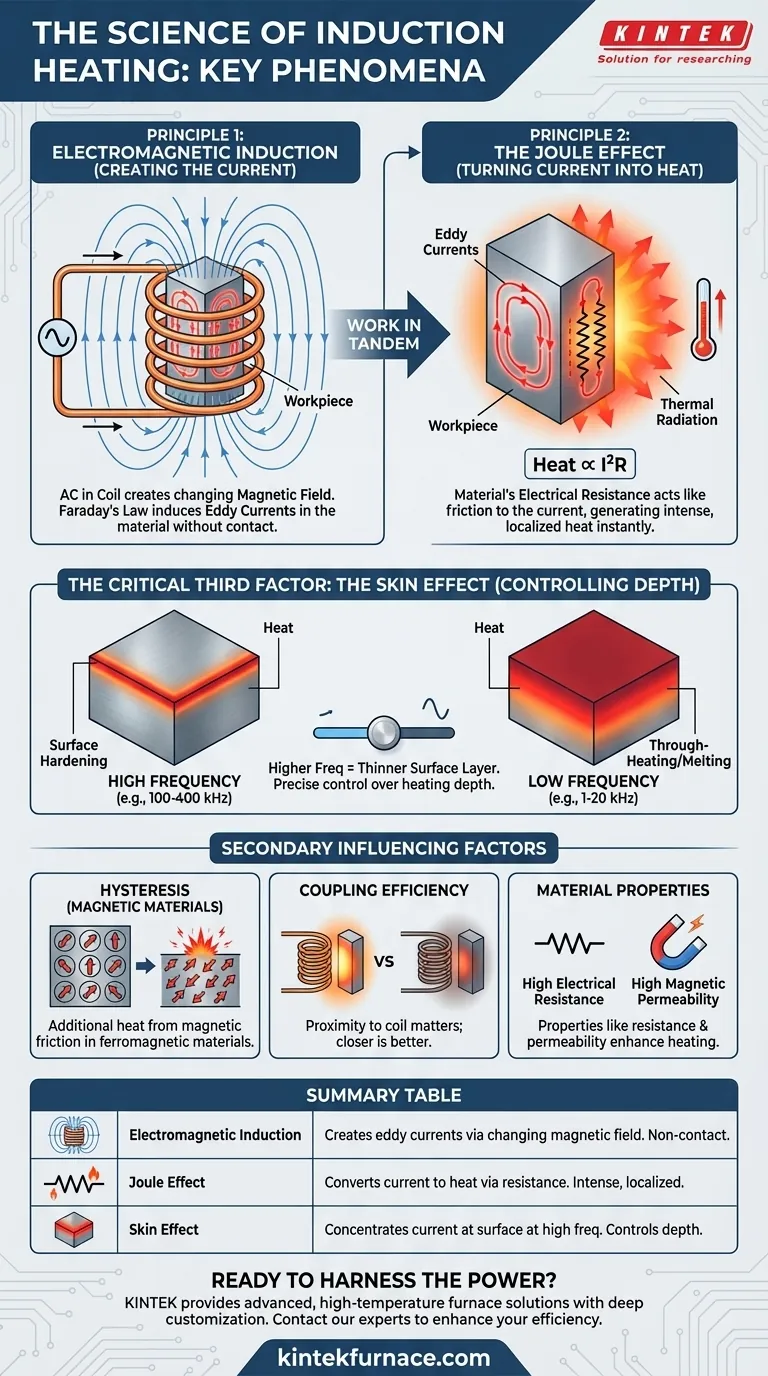

At its core, induction heating operates on two fundamental physical principles: Electromagnetic Induction, which creates an electrical current inside a material without physical contact, and the Joule Effect, which converts that current into heat. These two phenomena work in tandem, allowing for the precise and rapid heating of conductive materials.

Induction heating is a two-step process. First, a changing magnetic field induces a mirror current within a target material. Second, the material's own internal resistance causes that induced current to generate intense, localized heat.

Principle 1: Electromagnetic Induction – Creating the Current

To understand induction heating, you must first grasp how it generates an electrical current inside a solid object from the outside. This is the magic of electromagnetic induction.

The Role of the Induction Coil

An induction heating system uses a specially designed coil, typically made of copper tubing. A high-frequency alternating current (AC) is passed through this coil.

This AC current creates a powerful and rapidly changing magnetic field in the space around and within the coil.

Faraday's Law in Action

When a conductive material, like a piece of steel, is placed inside this changing magnetic field, Faraday's Law of Induction takes effect.

The law states that a changing magnetic field will induce an electrical current in any conductor placed within it. These are called eddy currents. They flow in closed loops within the material, mirroring the current in the external coil.

Principle 2: The Joule Effect – Turning Current into Heat

Simply creating a current is not enough; that current must be converted into thermal energy. This is where the second principle, the Joule effect, comes into play.

Electrical Resistance as Friction

Think of electrical resistance as a form of friction for moving electrons. Every conductive material has some level of resistance.

As the induced eddy currents flow through the material, they encounter this resistance. The energy lost in overcoming this "friction" is released directly as heat.

The Heat Generation Formula

This heating is described by the Joule effect, where the heat generated is proportional to the material's resistance multiplied by the square of the current (Heat ∝ I²R).

Because induction can create very large eddy currents, the resulting heat generation can be massive and almost instantaneous.

The Critical Third Factor: The Skin Effect

While induction and the Joule effect explain what happens, the Skin Effect explains where it happens. This phenomenon is critical for controlling the process.

What is the Skin Effect?

At high frequencies, alternating currents (like our eddy currents) do not use the entire volume of a conductor. They are forced to flow in a thin layer near the surface.

This phenomenon is known as the skin effect. The higher the frequency of the current, the thinner this surface layer becomes.

Why Frequency is Key to Control

The skin effect gives operators precise control over the heating depth.

High frequencies (e.g., 100-400 kHz) concentrate the heat on the immediate surface, which is ideal for surface hardening. Lower frequencies (e.g., 1-20 kHz) allow the magnetic field and eddy currents to penetrate deeper, resulting in through-heating for applications like forging or melting.

Understanding the Trade-offs and Secondary Effects

A complete understanding requires acknowledging factors that modify the core principles. These are not just theoretical details; they have major practical consequences.

Hysteresis: A Bonus for Magnetic Materials

For ferromagnetic materials like iron and steel (below their Curie temperature), a secondary heating effect occurs. Hysteresis losses are caused by the friction of magnetic domains rapidly realigning with the changing magnetic field. This adds to the heat generated by the Joule effect, making induction particularly effective for these materials.

Coupling Efficiency

The efficiency of energy transfer depends on the proximity of the workpiece to the coil. This is called coupling. A workpiece that is close to the coil and whose shape conforms to the coil's field will heat much more efficiently than one that is far away. Poor coupling wastes energy and slows the heating process.

Material Properties

The effectiveness of induction heating is highly dependent on the target material's properties. High electrical resistance contributes to more Joule heating. High magnetic permeability (in materials like iron) enhances both the induced currents and hysteresis losses, leading to much faster heating.

Applying This to Your Heating Goal

Understanding these principles allows you to select the right parameters for your specific industrial or scientific objective.

- If your primary focus is surface hardening: Use a high frequency to leverage the skin effect, concentrating intense heat on the surface for a shallow, hard case.

- If your primary focus is through-heating or melting: Use a lower frequency to ensure the magnetic field penetrates deep into the material for uniform heating.

- If your primary focus is heating magnetic steel: You will benefit from the combined power of the Joule effect and hysteresis losses, resulting in very efficient heating below the material's Curie point.

By mastering how these physical laws interact, you can transform induction from a concept into a precise and powerful thermal tool.

Summary Table:

| Phenomenon | Core Function | Key Takeaway |

|---|---|---|

| Electromagnetic Induction | Creates eddy currents within a material using a changing magnetic field. | Enables non-contact heating. |

| Joule Effect | Converts the induced electrical current into heat due to the material's resistance. | Generates intense, localized heat. |

| Skin Effect (Critical Factor) | Concentrates the current flow near the surface at high frequencies. | Allows precise control over heating depth. |

Ready to harness the power of induction heating for your application?

KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique thermal processing requirements.

Contact our experts today to discuss how our induction heating solutions can enhance your efficiency and results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing