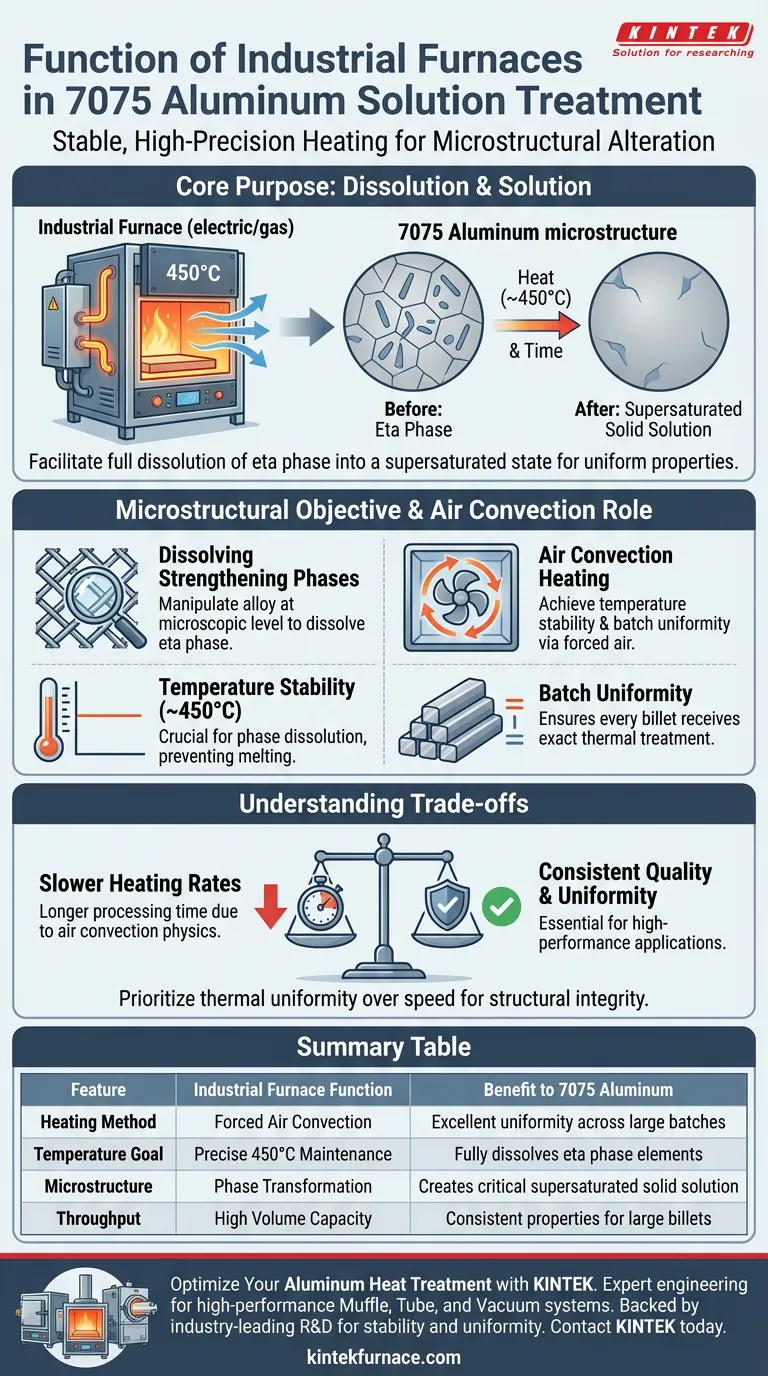

In the conventional solution treatment of 7075 aluminum alloy, industrial electric or gas furnaces serve as stable, high-precision heating environments designed to alter the metal's microstructure. Their primary function is to maintain a temperature of approximately 450°C via air convection, enabling internal strengthening elements to dissolve completely into the aluminum matrix.

The core purpose of these furnaces is to facilitate the dissolution of the eta phase to create a supersaturated solid solution, ensuring that large batches of billets achieve uniform mechanical properties despite the slower heating rate.

The Microstructural Objective

Dissolving the Strengthening Phases

The fundamental goal of using these furnaces is to manipulate the alloy at a microscopic level.

Specific internal strengthening components, known as the eta phase, must be fully dissolved to prepare the metal for subsequent aging processes.

Creating a Supersaturated Solid Solution

By holding the alloy at high temperatures, the furnace forces these distinct phases to merge with the aluminum.

This results in a supersaturated solid solution, which is the critical precursor state required to achieve the high strength characteristics associated with 7075 aluminum.

The Role of Air Convection Heating

Achieving Temperature Stability

Industrial furnaces utilize air convection heating to create a highly stable thermal environment.

Maintaining the temperature specifically around 450°C is crucial; deviations can fail to dissolve the phases or lead to melting of grain boundaries.

Ensuring Batch Uniformity

A key advantage of the conventional furnace is its ability to handle volume.

The convection mechanism ensures excellent temperature uniformity throughout the entire chamber, guaranteeing that every billet in a large batch receives the exact same thermal treatment.

Understanding the Trade-offs

Slower Heating Rates

While these furnaces excel at uniformity and stability, they are not the fastest option available.

The air convection method creates a slower heating rate compared to alternative, more direct heating technologies.

Efficiency vs. Cycle Time

This slower rate means the total processing time for solution treatment is longer.

Operators must accept extended cycle times as the "cost" for ensuring the consistent quality and phase dissolution required for high-performance aerospace or structural applications.

Making the Right Choice for Your Goal

When evaluating the use of industrial electric or gas furnaces for 7075 aluminum, consider your production priorities:

- If your primary focus is material consistency: Rely on these furnaces to guarantee that every part in a large batch achieves the necessary supersaturated state without thermal gradients.

- If your primary focus is cycle speed: Recognize that the physics of air convection will impose a bottleneck on heating rates, requiring careful scheduling to maintain throughput.

Success in solution treatment lies in prioritizing thermal uniformity over heating speed to ensure the structural integrity of the final alloy.

Summary Table:

| Feature | Industrial Furnace Function | Benefit to 7075 Aluminum |

|---|---|---|

| Heating Method | Forced Air Convection | Ensures excellent temperature uniformity across large batches |

| Temperature Goal | Precise 450°C Maintenance | Fully dissolves eta phase strengthening elements |

| Microstructure | Phase Transformation | Creates the critical supersaturated solid solution |

| Throughput | High Volume Capacity | Consistent mechanical properties for large industrial billets |

Optimize Your Aluminum Heat Treatment with KINTEK

Achieving the perfect supersaturated solid solution requires precision that only expert engineering can provide. KINTEK delivers high-performance Muffle, Tube, and Vacuum systems designed specifically for the rigorous demands of 7075 aluminum solution treatment.

Backed by industry-leading R&D, our furnaces offer the temperature stability and uniformity essential for aerospace and structural applications. Whether you need a standard setup or a fully customized high-temperature solution, we provide the equipment that turns material science into industrial success.

Ready to elevate your material properties? Contact KINTEK today to discuss your unique thermal processing needs.

Visual Guide

References

- Hao Wu, Richard Turner. Microstructure Characterisation and Modelling of Pre-Forging Solution Treatment of 7075 Aluminium Alloy Using Novel Heating Methods. DOI: 10.3390/jmmp9010002

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do high-pressure reaction environments facilitate the solvothermal synthesis of Ag2Se? Precision Phase Control

- Why is a N2 and SF6 gas protection system required for magnesium melting? Ensure Safety and Alloy Purity

- How does the use of carbon dioxide and a flow meter impact the physical activation of biochar? Master Pore Development

- What role does an industrial oven play in the pretreatment of oil palm shell for biochar? Ensure Peak Biomass Quality

- What is the purpose of using a laboratory blast drying oven at 107°C for 17 hours for reforming catalysts?

- How does industrial-scale forging equipment influence the morphology of primary carbonitrides in H13 tool steel?

- What factors should be considered when selecting a furnace based on material properties? Ensure Optimal Heat Treatment

- How does a vacuum drying oven contribute to the quality of crosslinked precursors? Expert Guide to Material Integrity