At its core, selecting a furnace requires you to understand your material's chemical reactivity. The primary factors are whether your material is sensitive to atmospheric gases like oxygen, which necessitates a vacuum, or if it requires a specific gaseous environment to achieve desired properties like hardness or corrosion resistance, which calls for an atmosphere furnace.

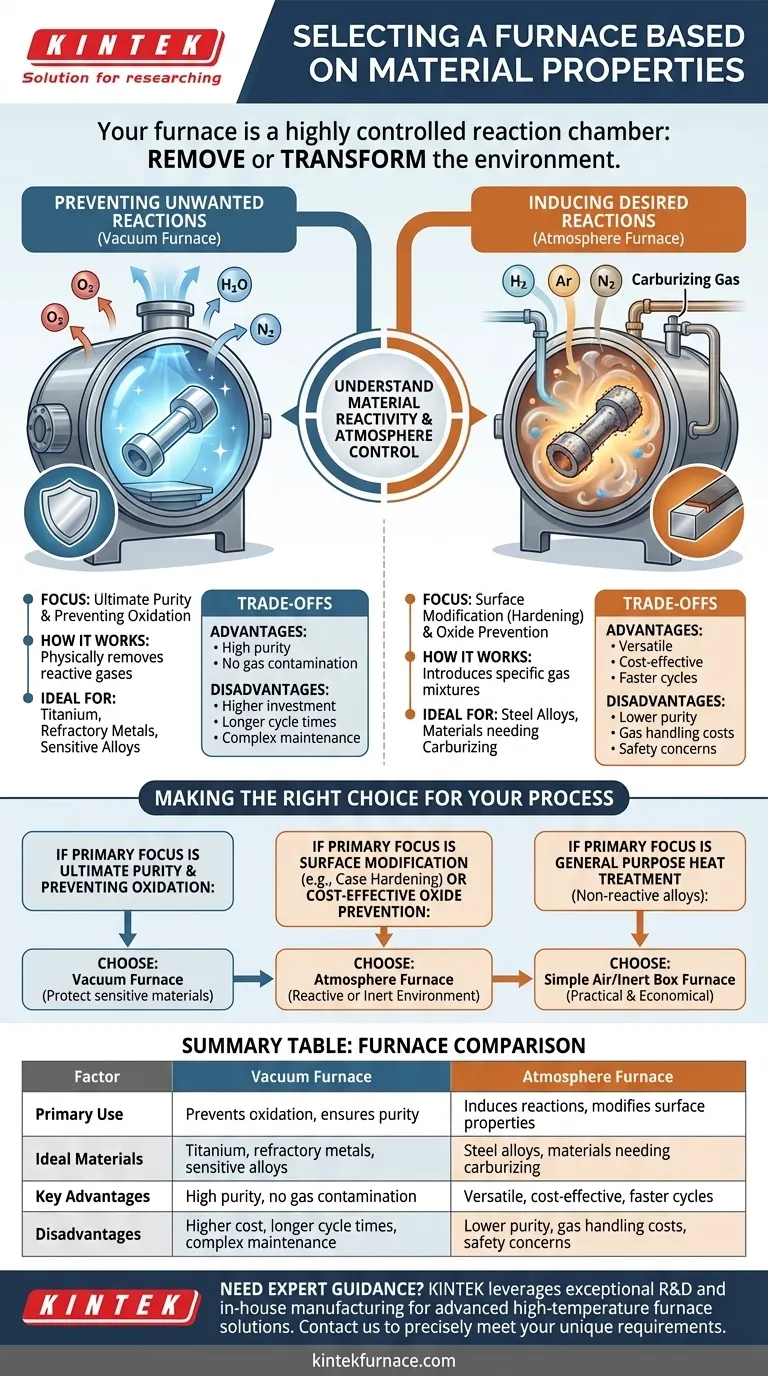

Your furnace is not just a heat source; it is a highly controlled reaction chamber. The fundamental choice is between removing the environment to protect your material (a vacuum furnace) or actively using a specific environment to transform it (an atmosphere furnace).

The Core Principle: Atmosphere Control

The most critical function of a modern industrial furnace, beyond reaching a target temperature, is managing the atmosphere surrounding the material. This atmosphere directly influences the final chemical and physical properties of your part.

Preventing Unwanted Reactions (Oxidation & Contamination)

Many advanced materials, especially at high temperatures, are highly reactive. When exposed to a standard air environment, they can readily form oxides on their surfaces.

This oxidation can be detrimental, leading to discoloration, compromised structural integrity, poor brazing or welding performance, and a failure to meet specifications. This is particularly true for materials like titanium, refractory metals, and certain stainless steels.

A vacuum furnace addresses this by physically removing the reactive gases (oxygen, nitrogen, water vapor) from the chamber, creating an ultra-clean environment that protects the material's purity.

Inducing Desired Reactions (Atmosphere Treatment)

Conversely, some processes intentionally introduce specific gases to create a chemical reaction. This is the domain of the atmosphere furnace, which can be filled with a precise gas mixture to alter a material's properties.

Common examples include:

- Reducing Atmospheres (e.g., Hydrogen): Used to remove surface oxides.

- Inert Atmospheres (e.g., Argon, Nitrogen): Used to prevent reactions without the cost or complexity of a deep vacuum.

- Carburizing Atmospheres: Used to introduce carbon into the surface of steel to increase hardness.

These treatments are essential for achieving outcomes like improved surface hardness, wear resistance, and overall strength in common materials like steel alloys.

Understanding the Trade-offs

Choosing a furnace involves balancing process requirements with operational realities. Each type comes with distinct advantages and disadvantages.

Vacuum Furnaces: Purity vs. Complexity

A vacuum furnace offers the ultimate control over environmental purity, making it non-negotiable for sensitive applications in aerospace, medical, and electronics.

However, this precision comes at a cost. Vacuum furnaces typically have a higher initial investment, longer cycle times due to the need to pump down the chamber, and more complex maintenance requirements for pumps and seals.

Atmosphere Furnaces: Versatility vs. Purity

Atmosphere furnaces, including many common box furnaces, are the workhorses of the heat-treating industry. They are highly versatile and cost-effective for processes like hardening, annealing, and sintering.

The trade-off is a lower level of purity. While an inert gas atmosphere prevents most oxidation, it cannot match the cleanliness of a high vacuum. Furthermore, they introduce the ongoing cost and safety management associated with handling large volumes of process gases.

Making the Right Choice for Your Process

Your decision should be guided by the final state you need your material to be in.

- If your primary focus is ultimate purity and preventing any oxidation: A vacuum furnace is the correct choice to protect sensitive materials.

- If your primary focus is surface modification (like case hardening) or cost-effective oxide prevention: An atmosphere furnace provides the necessary reactive or inert environment.

- If your primary focus is general-purpose heat treatment of non-reactive alloys: A simple air or inert-atmosphere box furnace is often the most practical and economical solution.

Ultimately, aligning the furnace's environmental capabilities with your material's intrinsic properties is the key to achieving predictable and successful results.

Summary Table:

| Factor | Vacuum Furnace | Atmosphere Furnace |

|---|---|---|

| Primary Use | Prevents oxidation, ensures purity | Induces reactions, modifies surface properties |

| Ideal Materials | Titanium, refractory metals, sensitive alloys | Steel alloys, materials needing carburizing |

| Key Advantages | High purity, no gas contamination | Versatile, cost-effective, faster cycles |

| Disadvantages | Higher cost, longer cycle times, complex maintenance | Lower purity, gas handling costs, safety concerns |

Need expert guidance on selecting the perfect furnace for your materials? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?